Method for manufacturing composite section bar coated with cladding material and dedicated die thereof

A technology of coating materials and composite profiles, which is applied in the manufacture of composite profiles coated with coating material layers and the field of special molds, which can solve the problems of easy-to-damage polymer composite material layer surface appearance, high production cost, complicated operation, etc. problems, to achieve the effect of improving mechanical strength and electrical breakdown resistance insulation performance, reducing repair rate and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

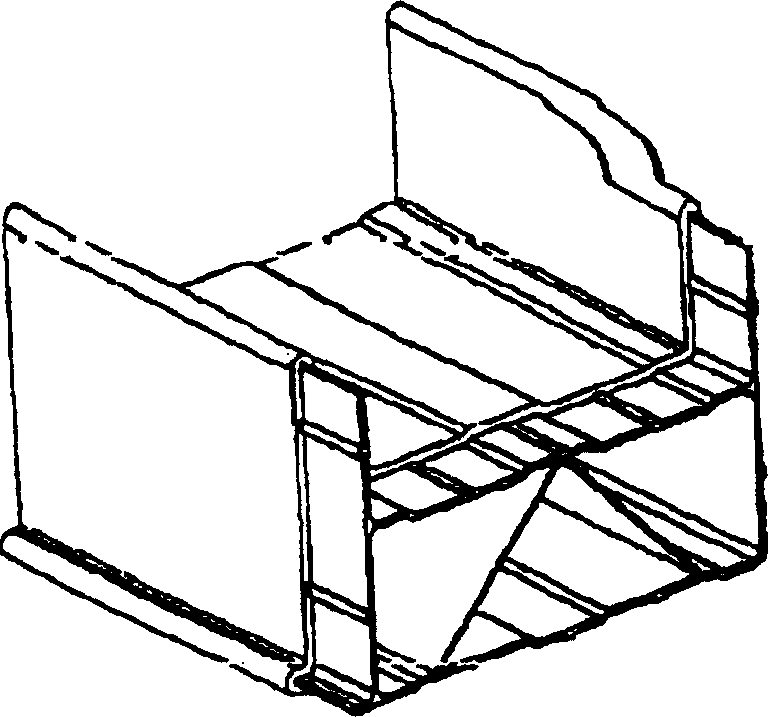

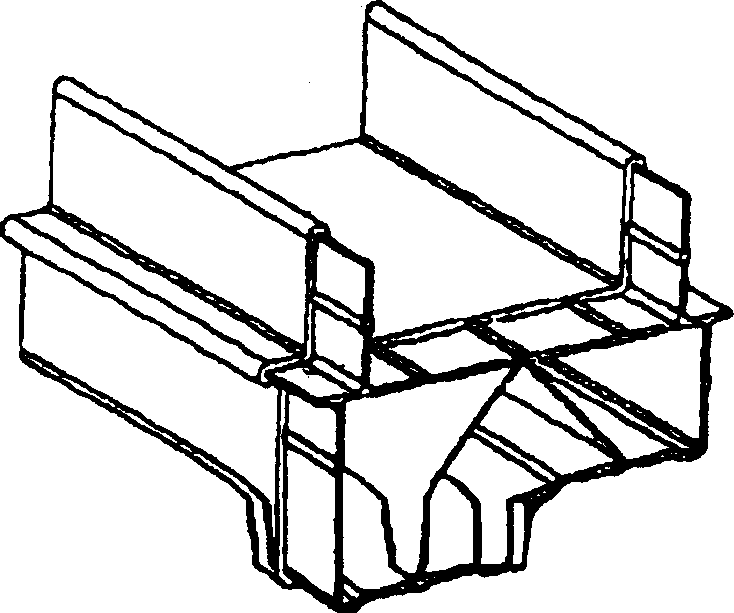

[0046] Figure 2A -2D shows the three-dimensional schematic diagram of four kinds of aluminum alloy composite profiles commonly used in practice. In various engineering practices, it is often used to coat the outer surface of aluminum alloy profiles of various cross-sectional shapes with high Aluminum alloy composite profiles with molecular composite layers.

[0047] The manufacturing method of the said composite profile of this invention is as follows.

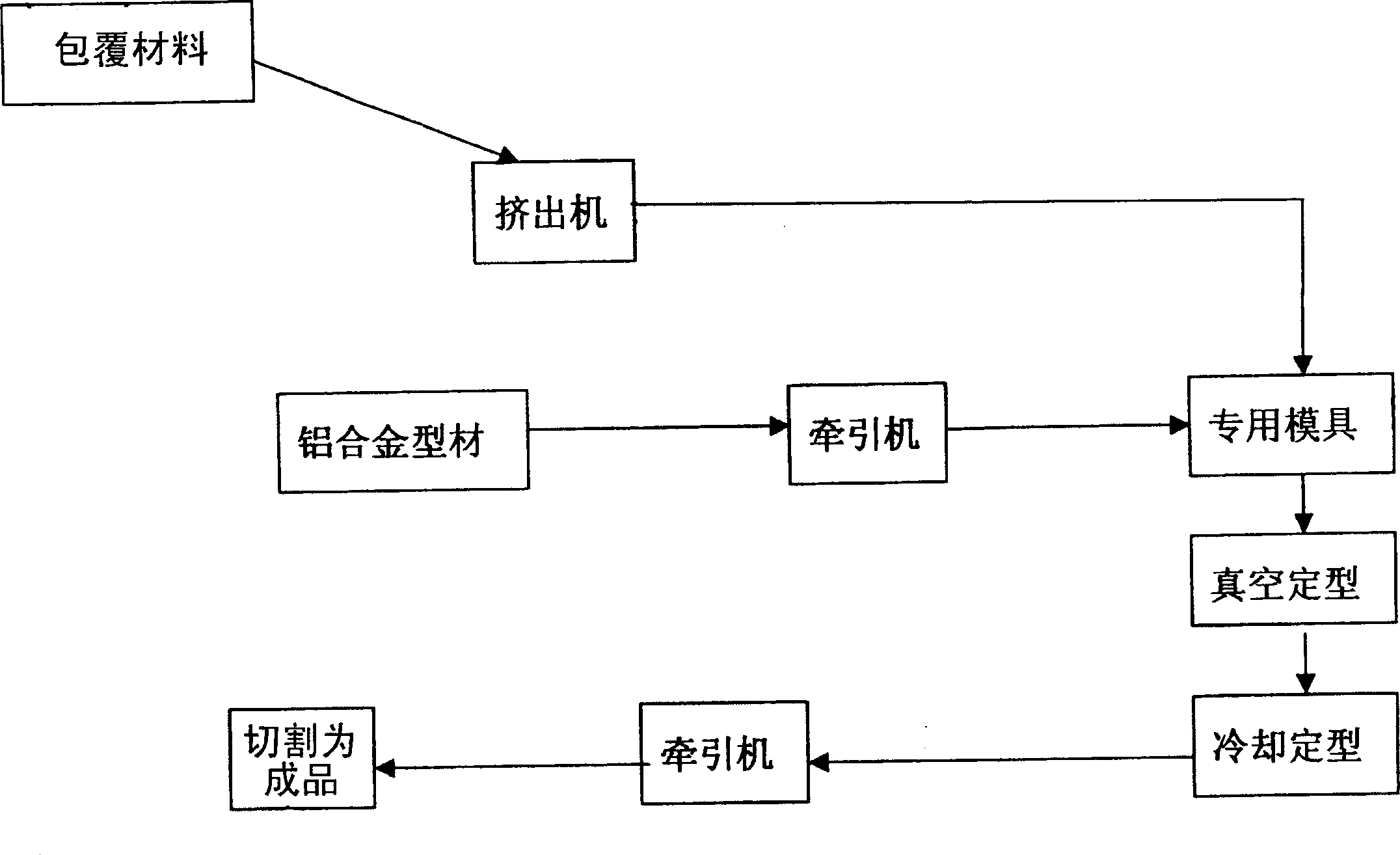

[0048] figure 1 Shown is the manufacturing process flow of the aluminum alloy composite profile covered with cladding material layer in this embodiment. Such as figure 1 and image 3 As shown, first, according to the prior art, based on various uses, the polymer coating material is granulated and shaped according to different formulas, and then the granulated solid powder polymer coating material is transported into the Extrusion is performed in the hopper of the extruder 2, so that after the processing of the extruder 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com