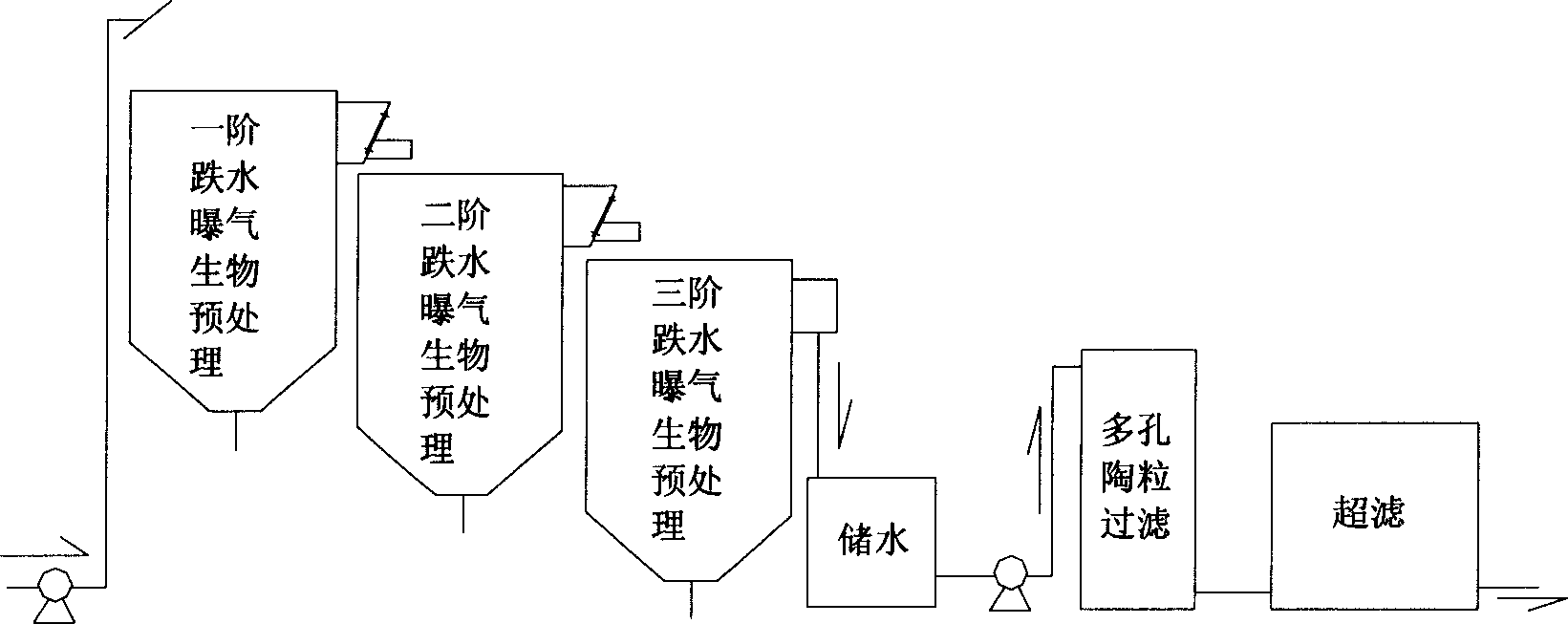

Dropping, aeration and biological pretreatment- super filtering combined drinking water purification process

A technology of biological pretreatment and water drop aeration, applied in the field of drinking water treatment, can solve the problems of low removal rate of organic matter in water, inability to remove ammonia nitrogen, high water quality of drinking water, etc. Safe, long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

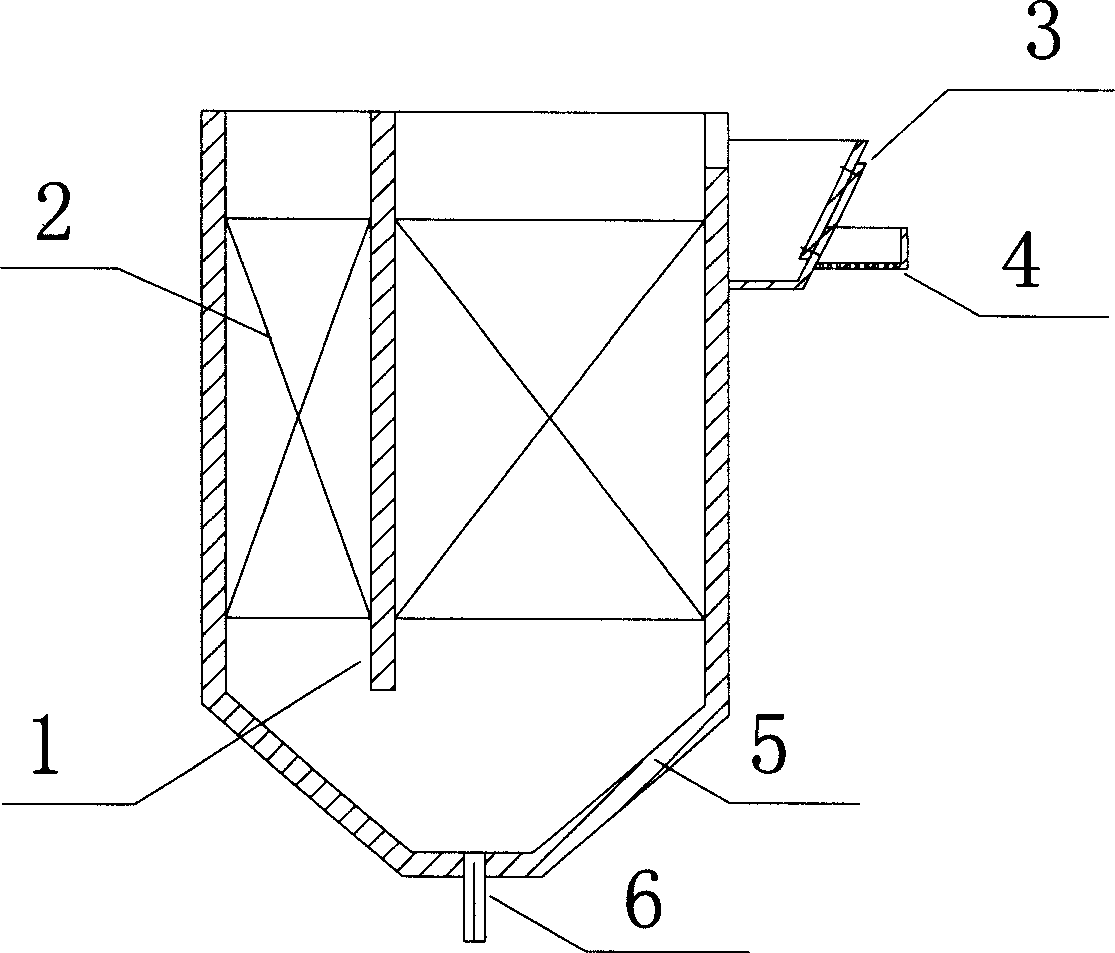

[0019] see figure 1 and 2 . First construct the biological pretreatment device of multi-stage falling water aeration, the present invention adopts three-stage (according to the degree of organic pollution of water quality, also can be greater than three-stage) the biological contact oxidation reactor of falling water aeration, each stage biological contact oxidation The filling volume of the filler 2 in the reactor is equal, and the filler 2 is divided into two parts by the deflector 1. A drop weir 3 is set near the end face of the reactor, and a surrounding barrier is provided under the drop weir 3. The water drop porous baffle 4, the inner diameter of the holes of the drop water porous baffle 4 is 3-5mm, and other structures are similar to general bioreactors. The drop height of each stage is 0.3m, and the total hydraulic retention time (HRT) of the biological contact oxidation reactor is about 1.5 hours. 1 After the filler 2 on one side is divided into two parts, it clim...

Embodiment 2

[0022] Same as in Example 1, first build five biological contact oxidation reactors to form a five-stage falling water aeration biological pretreatment device, and then raise the raw water to be treated at one time, and at a height of 0.5m, the biological contact oxidation Under the condition that the total hydraulic retention time (HRT) of the reactor is about 2.0 hours, the step-by-step drop water oxygenation and biological contact oxidation treatment, the use of biological drop water oxygenation biological pretreatment removes most of the ammonia nitrogen, trace organic matter and algae in the water and other substances, and then the turbidity of the water is further reduced after being filtered by the porous ceramsite filter. The effluent water meets the drinking water quality standard.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com