Middle content chromium copper, iron-containing antiseptic anticreas rustless steel sheet belt and its production method

A stainless steel plate, copper and iron technology, applied in the direction of manufacturing tools, temperature control, metal rolling, etc., can solve the problems such as the surface quality, formability and wrinkle resistance of copper-containing stainless steel, and the inability to produce cold-rolled strips, etc. Achieve the effect of good cold formability and surface wrinkle resistance, beautiful surface quality, good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The specific implementations of the chromium-containing copper-containing ferrite antibacterial and anti-wrinkle stainless steel cold-rolled strip and its manufacturing method will be described in detail below in conjunction with the examples. The specific implementation mode is not limited to the following examples.

[0047] Example 1 of medium chromium copper-containing ferrite antibacterial and anti-wrinkle stainless steel cold-rolled strip

[0048] The composition of this embodiment is (weight %):

[0049] C 0.03 N 0.04 Si 0.60 Mn 0.80 P 0.04

[0050] S ≤0.02 Cr 17.0 Cu 1.30 Ni 1.20 Mo 1.40

[0051] Ti 0.40 Nb 0.30

[0052] The rest is the balance element Fe and unavoidable impurity elements.

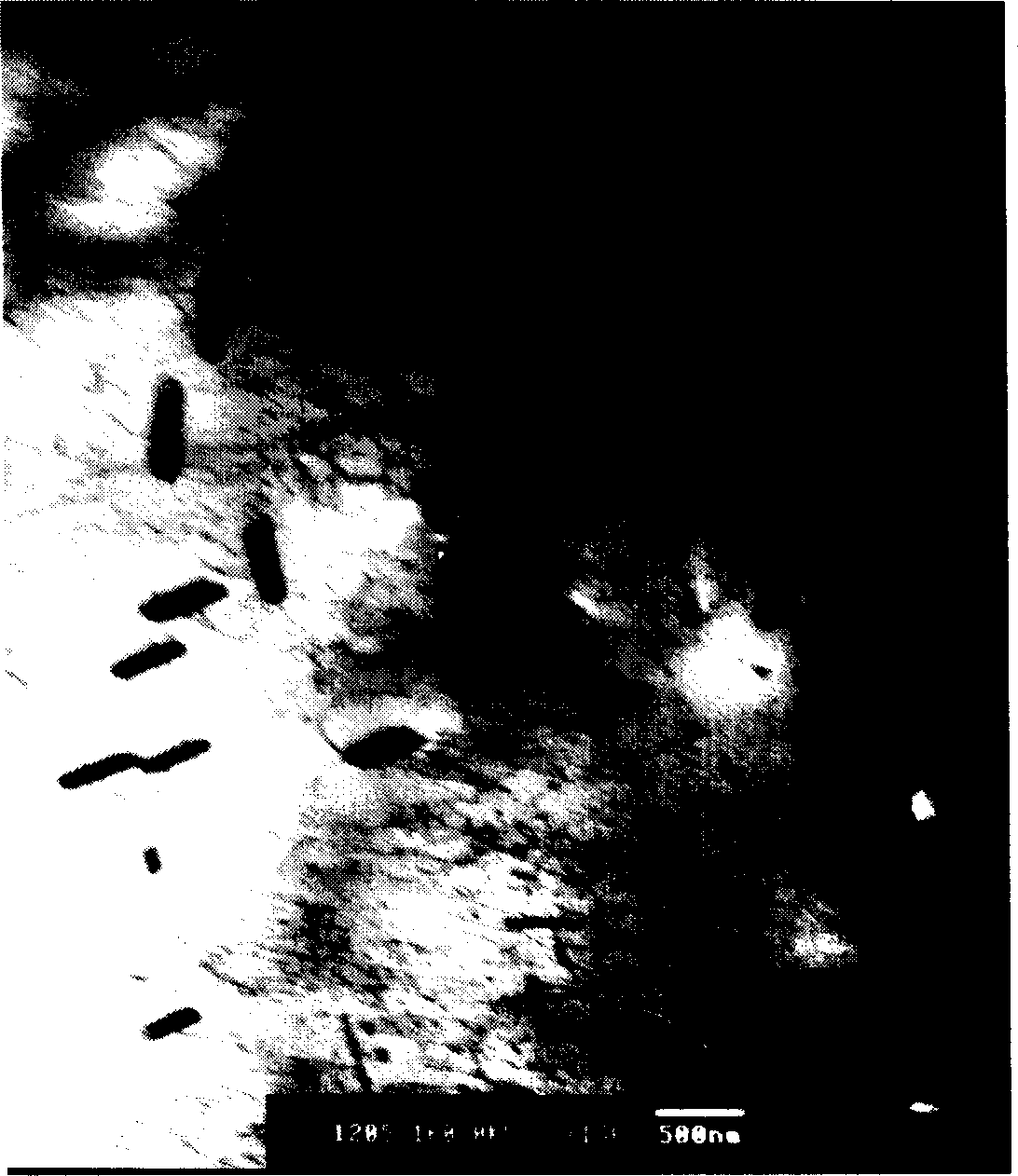

[0053] In the cold-rolled stainless steel strips after hot rolling, cold rolling of one rolling process, multiple annealing and pickling, copper-rich precipitates with a particle size of 0.1-0.5 μm are dispersed in the stainless steel matrix and their total area is The r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com