Compounding process of concrete hydration reducer

A preparation method and heat of hydration technology, applied in the field of concrete admixtures, can solve the problems of backward temperature control measures, limited temperature reduction, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

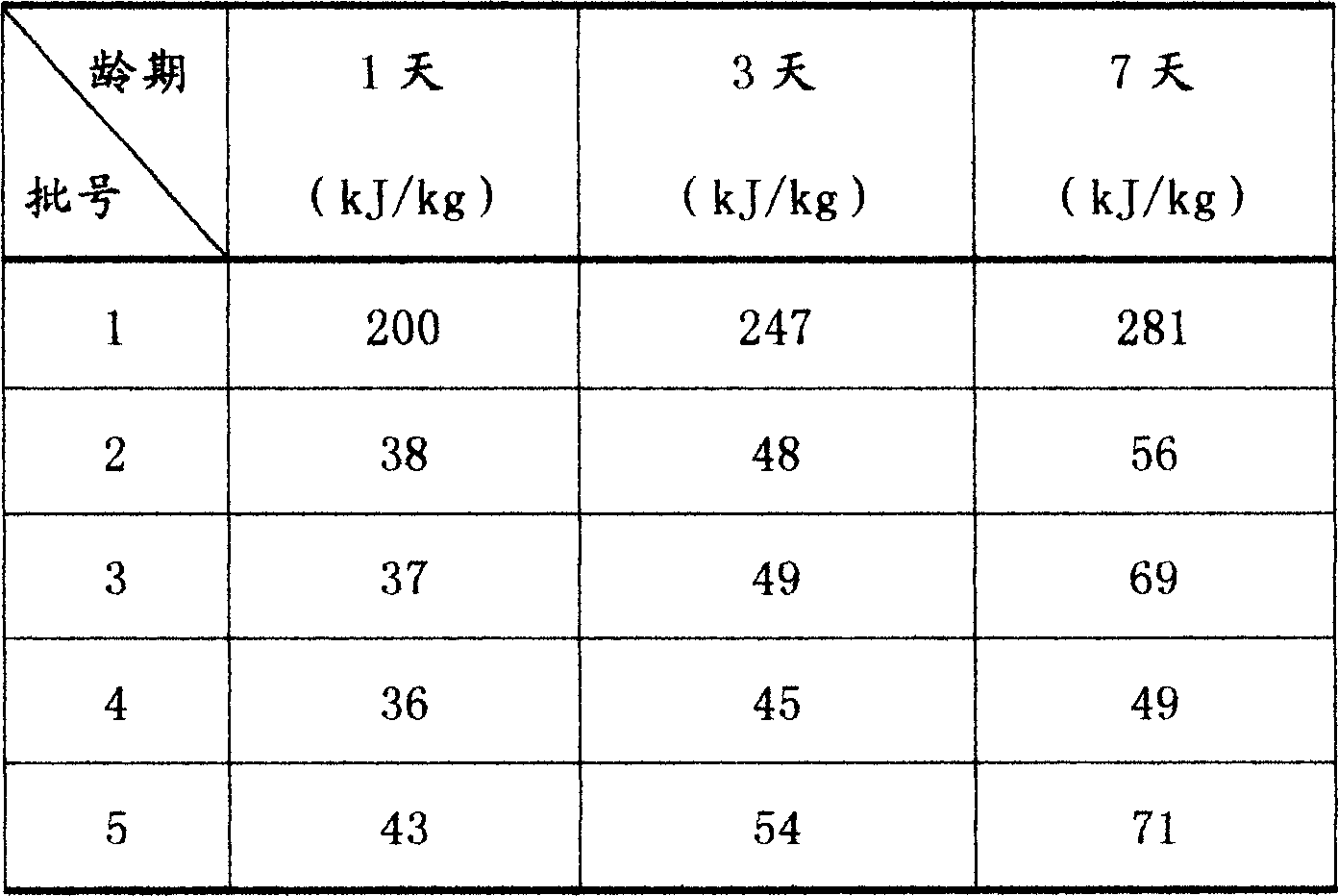

Image

Examples

Embodiment 1

[0008] Will be selected from polyacrylic acid-starch graft, polyglycolic acid-lactic acid copolymer, modified starch, polyglycolic acid-lactic acid copolymer, polyformamide, polymethyl methacrylate, polyacrylonitrile alkyl ester and ethyl A raw material in the base cellulose is dissolved in water; reacted at 5-55°C, and the reacted water phase and solid phase are separated, and the separated solid phase is the concrete hydration heat reducer; the separated solid phase is Drying; crushing, the fineness is less than 0.315mm. The selected from polyacrylic acid-starch graft, polyglycolic acid-lactic acid copolymer, modified starch, polyglycolic acid-lactic acid copolymer, polyformamide, polymethyl methacrylate, polyacrylonitrile alkyl ester and The molar ratio of a raw material in ethyl cellulose to water is: 1:1-50.

Embodiment 2

[0010] Will be selected from polyacrylic acid-starch graft, polyglycolic acid-lactic acid copolymer, modified starch, polyglycolic acid-lactic acid copolymer, polyformamide, polymethyl methacrylate, polyacrylonitrile alkyl ester and ethyl A raw material in the base cellulose is dissolved in water; react at 10-50°C, and separate the reacted water phase and solid phase, and the separated solid phase is the concrete hydration heat reducer; the separated solid phase is Drying; crushing, the fineness is less than 0.315mm. The selected from polyacrylic acid-starch graft, polyglycolic acid-lactic acid copolymer, modified starch, polyglycolic acid-lactic acid copolymer, polyformamide, polymethyl methacrylate, polyacrylonitrile alkyl ester and The molar ratio of a raw material in ethyl cellulose to water is: 1:5-40.

Embodiment 3

[0012] Will be selected from polyacrylic acid-starch graft, polyglycolic acid-lactic acid copolymer, modified starch, polyglycolic acid-lactic acid copolymer, polyformamide, polymethyl methacrylate, polyacrylonitrile alkyl ester and ethyl A raw material in the base cellulose is dissolved in water; react at 15-40°C, and separate the reacted water phase and solid phase, and the separated solid phase is the concrete hydration heat reducer; the separated solid phase is Drying; crushing, the fineness is less than 0.315mm. The selected from polyacrylic acid-starch graft, polyglycolic acid-lactic acid copolymer, modified starch, polyglycolic acid-lactic acid copolymer, polyformamide, polymethyl methacrylate, polyacrylonitrile alkyl ester and The molar ratio of a raw material in ethyl cellulose to water is: 1:8-35.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com