Prepn process of SiN ceramic with high heat conductivity

A technology of silicon nitride ceramics and high thermal conductivity, which is applied in the preparation of high thermal conductivity silicon nitride ceramics, low-temperature rapid sintering to prepare high thermal conductivity silicon nitride ceramics, can solve the problems that have not yet been seen in high thermal conductivity silicon nitride ceramics, and achieve Excellent thermal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

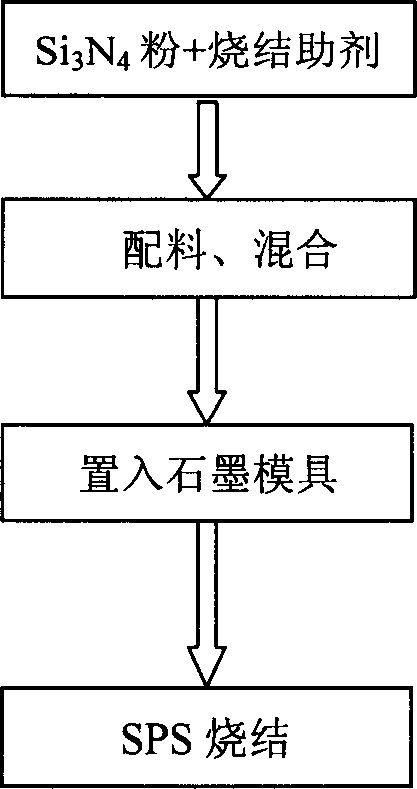

[0021] Add 3wt% sintering aid MgSiN 2 After the powder is evenly mixed, it is then loaded into a graphite mold, and SPS is sintered under the conditions of 60MPa, 1500°C, and a holding time of 12 minutes. After sintering, the samples were cooled to room temperature with the furnace.

[0022] The thermal conductivity of silicon nitride ceramics prepared by the above process can reach 100W / m K, and the three-point flexural strength σ b Up to 946MPa, Vickers hardness is 17GPa, fracture toughness is 7.41MPam 1 / 2 . The corrosion morphology of the polished surface is as follows: figure 2 shown.

Embodiment 2

[0024] Add 5wt% sintering aid MgSiN 2 After the powder is evenly mixed, it is then loaded into a graphite mold, and SPS is sintered under the conditions of 30MPa, 1550°C, and a holding time of 12 minutes. After sintering, the samples were cooled to room temperature with the furnace.

[0025] The thermal conductivity of silicon nitride ceramics prepared by the above process can reach 112W / m K, and the three-point flexural strength σ b 800MPa, Vickers hardness 16.5GPa, fracture toughness 7.68MPam 1 / 2 .

Embodiment 3

[0027] Add 9wt% sintering aid MgSiN 2 After the powder is uniformly mixed, it is then loaded into a graphite mold, and SPS is sintered under the conditions of 20MPa, 1550°C, and a holding time of 5 minutes. After sintering, the samples were cooled to room temperature with the furnace.

[0028] The thermal conductivity of silicon nitride ceramics prepared by the above process can reach 63W / m K, and the three-point flexural strength σ b is 900MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com