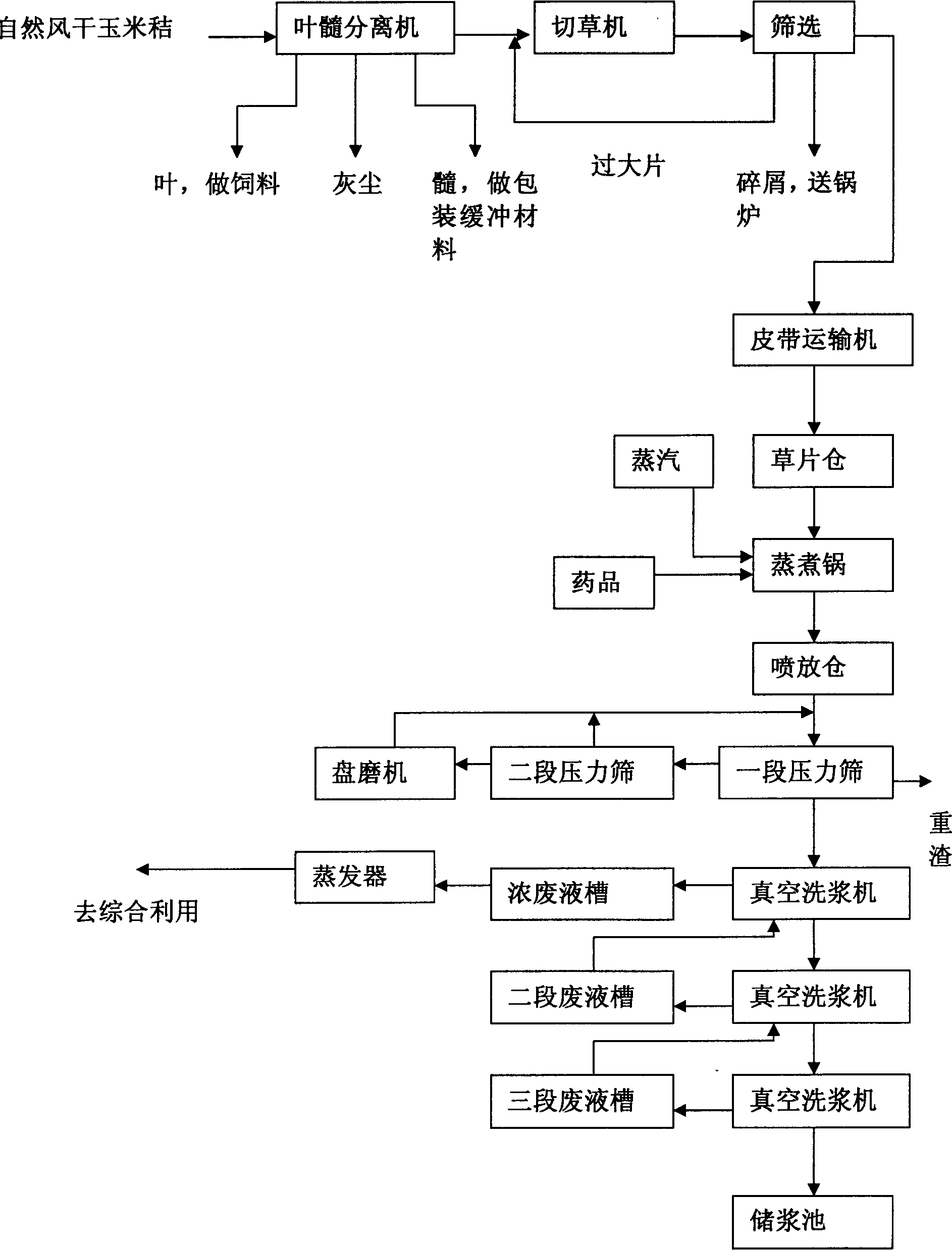

Process of preparing chemical pulp with corn stalk peel

A corn stalk and chemical pulping technology, which is applied to pulping with inorganic alkali, pulping with organic solvent, pulping with acid salt/acid anhydride, etc., can solve the problems of complicated production process, long cooking time, waste liquid pollution, etc. , to achieve significant economic and social benefits, advanced product quality, and shortened cooking time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0014] Example 1: pulping by AS-AQ method. Remove the leaves and leaf sheaths from the air-dried corn stalks produced in Dalian, and remove the pith. 2 SO 3 and NaOH, the total dosage is 13% (as Na 2 O meter), sulfitation degree 0.55, anthraquinone consumption 0.1%, liquid ratio 4: 1. After the cooking pot is packaged, run it dry for 10 minutes, then raise the temperature to 110°C and release steam to zero pressure (gauge pressure), continue to heat up to the highest temperature of 145°C, and keep the temperature at the highest temperature for 80 minutes. Then put the pot, utilize this condition to cook, can make yield rate 52.85%, Kappa number 10.8, bleaching rate 2.4%, viscosity 1264ml / g, unbleached pulp whiteness 39.6% ISO corn stalk AS-AQ pulp. It can be seen from the above data that the method of the present invention has lower dosage and lower cooking temperature, but the cooking speed is much faster than the above-mentioned prior art of corn stalk pulping.

[0015] ...

example 3

[0016] Example 3: NS-AQ pulping. Remove the leaves and leaf sheaths from the air-dried corn stalks produced in Dalian, and remove the pith. 2 SO 3 and Na 2 CO 3 , the total dosage is 13% (as Na 2 O meter), sulfitation degree 0.60, anthraquinone consumption 0.1%, liquid ratio 4: 1. After the cooking pot is packaged, run it dry for 10 minutes, then raise the temperature to 110°C and release steam to zero pressure (gauge pressure), continue to heat up to the highest temperature of 170°C, and hold the temperature for 85 minutes at the highest temperature. Then put the pot, utilize this condition to cook, can make yield rate 53.12%, kappa number 9.1, bleaching rate 1.8%, viscosity 1268ml / g, unbleached pulp whiteness 42.7%ISO corn stalk NS-AQ pulp.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com