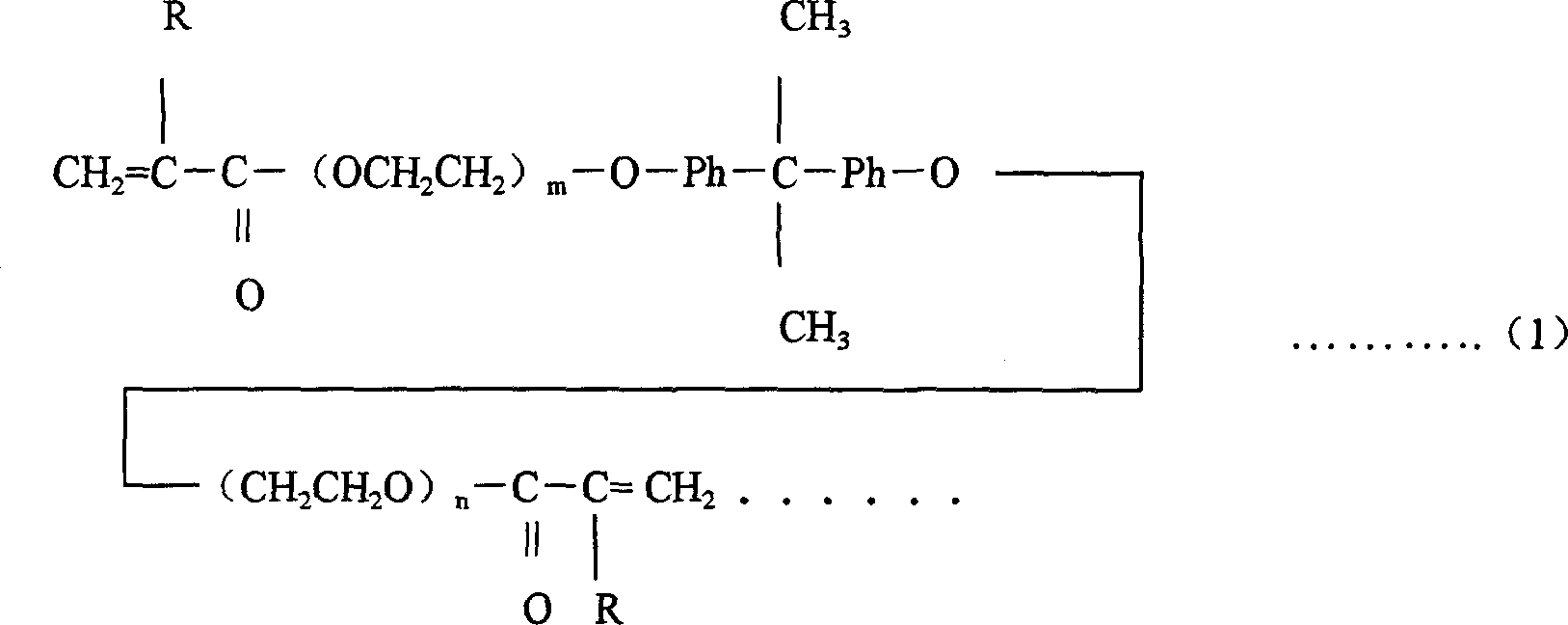

Photocurable resin composition, and its preparing method and use

A resin composition and composition technology, applied in the field of materials, can solve problems such as insufficient curing degree and short curing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

application example 1

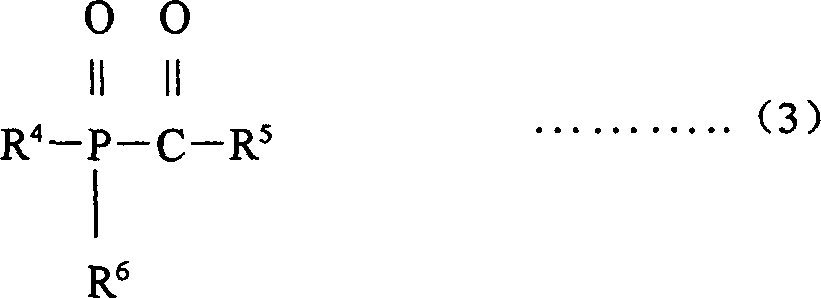

[0097] To 100 parts of vinyl ester resin [VE-1], add 1.5 parts of a diacylphosphine oxide compound photoinitiator that is photosensitive to all light in the wavelength range from ultraviolet light to visible light: two (2, 4, 6- Trimethylbenzoyl)-phenylphosphine oxide (trade name: Irgacure 819, produced by Ciba Seika Co., Ltd., hereinafter referred to as I-819), obtained a photocurable resin composition-1 capable of photosensitivity to all light in the wavelength range from ultraviolet light to visible light. The composition contains Hydroxyl amine compounds.

[0098] Then pour the photocurable resin composition into a frame made of glass plate to a thickness of 3 mm, and then use a 2KW metal halide lamp [trade name: Dynabeam2, manufactured by Toshiba Lighting Technology Co., Ltd.], which is a visible light source. Irradiate it at a distance of 1m for ten minutes to fully cure it. The bending strength and Barcol hardness (BH) of the obtained molded panels were measured. T...

comparative example 1

[0100] A room temperature curing catalyst butanone peroxide / cobalt naphthenate (Co: 6%)=1.0 part / 0.5 part was added to 100 parts of vinyl ester resin [VE-1] to obtain room temperature curable resin composition-1.

[0101] Then, the room temperature curable resin composition-1 was poured into a frame made of glass plate so that the thickness reached 3 mm, and it was left at room temperature for 24 hours to be cured at room temperature. Then prepare a molded plate that has undergone secondary post-curing for two hours at 120° C., and measure the flexural strength and Barcol hardness (BH) of the molded plate. The results are shown in Table 1. It can be seen from Table 1 that when the room temperature curable resin composition-1 is cured at room temperature, the same hardness as room temperature curing + secondary post-curing cannot be obtained even after curing for 24 hours. Resin composition-1 can obtain hardness and physical properties equivalent to room temperature curing + s...

application example 2

[0104] To 100 parts of unsaturated polyester resin UP-1, add 3.0 parts of 2,4,6-trimethylbenzoyl diphenylphosphine oxide (trade name: Darocur TPO, produced by Ciba Seika Co., Ltd.) and 0.3 parts of copper naphthenate to obtain a photocurable resin composition-2 with metal salts and photosensitive to all light in the wavelength range from ultraviolet to visible light.

[0105] Add 1.5 parts of I-819, 0.5 parts of cobalt naphthenate, and 1.2 parts of butanone peroxide to 100 parts of polyester methacrylate resin UPM-1 to obtain resin composition-3 with room temperature curing function and light curing function.

[0106] Then use photocurable resin compositions -2 and -3, according to the surface mat +450g / cm 2 The laminated product structure of 3 layers of chopped strand mat + surface mat, so that the glass fiber content reaches 25wt%, and then a visible light source 250W metal halide lamp [manufactured by Mitsubishi Electric Corporation] is irradiated for 15 minutes from a di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com