Double-face glass fibre board and production thereof

A glass fiber board and manufacturing method technology, applied in chemical instruments and methods, glass/slag layered products, sheets/boards, etc., can solve the problems of single function, high cost, low strength, etc. Long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

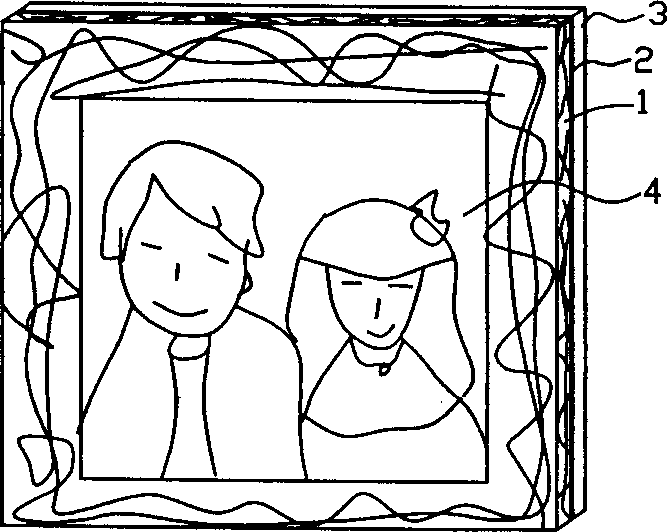

[0046] The first embodiment of the present invention is such as figure 1 As shown, the double-sided fiberglass board includes a crystal glue layer 1 and a glass fiber layer 2 made of glass fiber cloth and a surface glue layer 3, wherein the glass fiber layer is placed between the crystal glue layer and the surface glue layer; A filler is placed between layer 1 and fiberglass layer 2 (as in one photo 4). Therefore, the double-layer fiberglass board has a permanent commemorative value, and the fiberglass board can also be placed anywhere for decoration, and can also be used as a gift to relatives and friends, because the main raw materials of its crystal glue layer and surface glue layer are all different. Saturated resin for durability and long shelf life.

[0047] The method of manufacturing the first embodiment of the present invention is as follows:

[0048] Take the first mold, such as Figure 5Described, described first mold comprises a bottomed outer frame 10, the bott...

no. 2 example

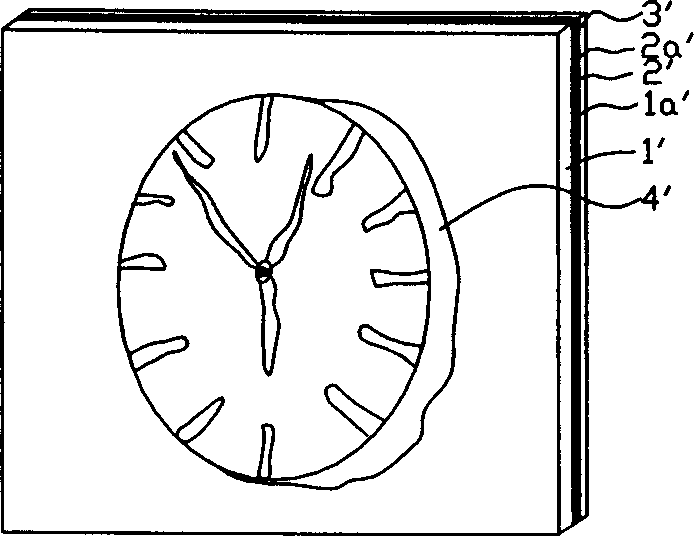

[0057] The second embodiment of the present invention is such as figure 2 As shown, the double-sided fiberglass board includes crystal glue layers 1', 1'a and glass fiber layers 2', 2a' made of glass fiber mats and a surface glue layer 3', and the glass fiber layer 2a' is attached to the surface The glue layer 3', the crystal glue layer 1a' is arranged between the glass fiber layer 2a' and the glass fiber layer 2', the glass fiber layer 2' is close to the crystal glue layer 1' on one side, and the other side is close to the crystal glue layer 1a '; There is a watch 4' between the crystal glue layer 1' and the glass fiber layer 2'. Therefore, the double-layer fiberglass board can be used as a clock and can be used to decorate indoors or outdoors. Meanwhile, the crystal glue layer and the surface glue layer are unsaturated resins, which are durable and can protect the clock inside.

[0058] The method for manufacturing the double-sided glass plate in the second embodiment of t...

no. 3 example

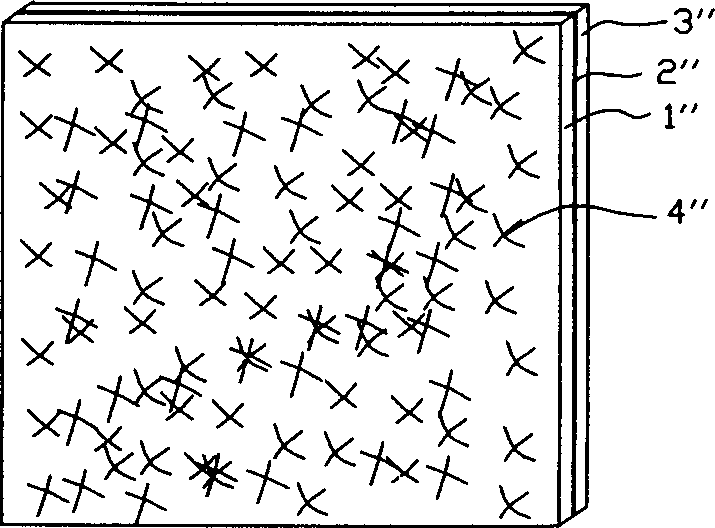

[0070] The third embodiment of the present invention is such as image 3 As shown, the double-sided fiberglass board includes crystal glue layers 1", 3" and a glass fiber layer 2" made of glass fiber cloth, and the glass fiber layer 2" is arranged on the crystal glue layer 1" and the crystal glue layer 3". Between; the crystal glue layer 1" and the crystal layer 3" are provided with a laser strip 4". The laser strip itself can emit light, while the crystal glue is transparent, so that the double-sided fiberglass board can emit beautiful light at night and can It is installed on the exterior of the building to play a decorative role, especially at night, and it can also form a special pattern through multiple pieces of the same double-sided glass.

[0071] The method for manufacturing the double-sided glass plate in the third embodiment of the present invention is as follows:

[0072] Take the first mold, such as Figure 5 Described, described first mold comprises a bottomed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com