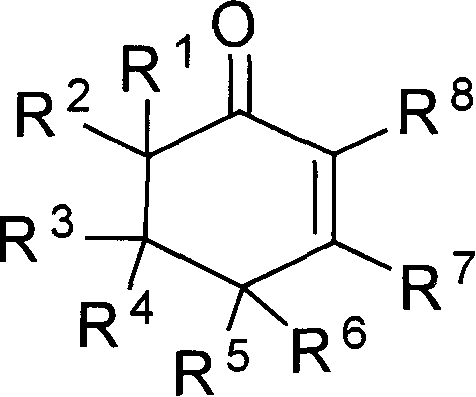

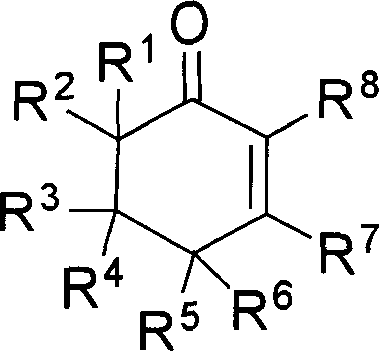

2-cyclohexenones and process for preparing same

A technology for cyclohexenones and compounds, which is applied in the field of 2-cyclohexenones and their preparation, can solve problems such as synthesis limitations and restrictions, and achieve good yields, easy operation, and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

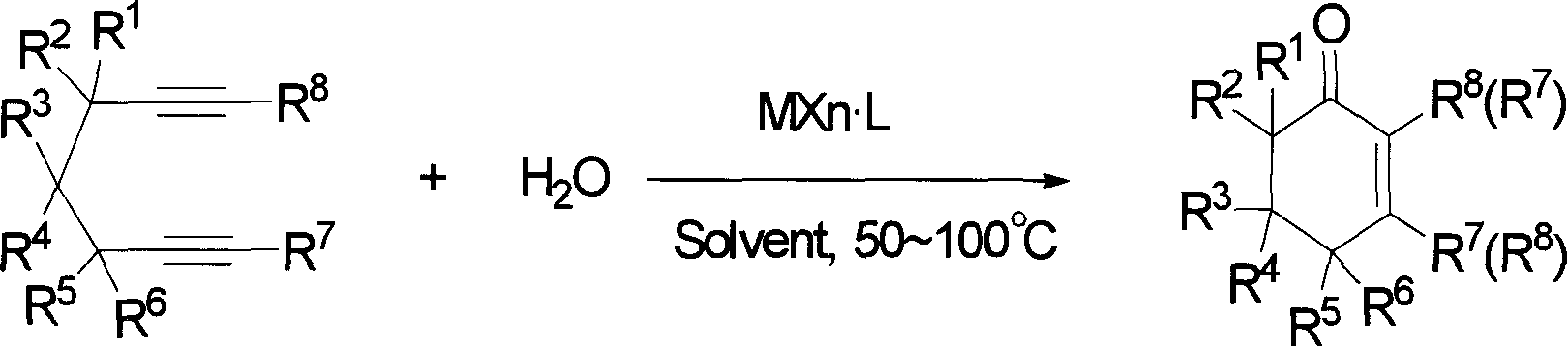

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1: the preparation of 3-methyl-5,5-dimethyl carboxylate-2-cyclohexenone

[0020] Dimethyl 2,2-dipropargyl malonate (104.1 mg, 0.5 mmol), methyl gold complex (MeAuPPh 3 , 5mg, 0.01mmol), trifluoromethanesulfonic acid (100μL, 0.5mmol), water (100μL, 5.0mmol) and n-octane (50μL, internal standard substance for GC analysis) were mixed in methanol (2.0mL), and The mixed solution was heated at below 50° C. for 1 hour to react. After the reaction, according to gas chromatography analysis, the target compound was confirmed with a yield of 94%. Then, the reaction mixture was subjected to column chromatography (silica gel column; developing solvent: petroleum ether: ethyl acetate=5:1; R f =0.3) Separation and purification to obtain the target compound 95mg (yield 84%), and carried out boiling point, NMR, IR, mass analysis and elemental analysis, the results are as follows: Bp: 120 ° C (5mm Hg); 1 H NMR (499.10MHz, CDCl 3 ): δ2.01(s, 3H), 2.87(s, 2H), 2.90(s, 2H), 3....

Embodiment 2

[0021] Example 2: Preparation of 3-methyl-5,5-carbomethoxy-2-cyclohexenone

[0022] The operation was referred to Example 1, except that heterophosphotungstic acid was used instead of trifluoromethanesulfonic acid to obtain 55 mg of the target compound (yield 48%).

Embodiment 3

[0023] Example 3: Preparation of 3-methyl-5,5-carbomethoxy-2-cyclohexenone

[0024] Refer to Example 1 for the operation, except that heterophosphomolybdic acid was used instead of trifluoromethanesulfonic acid to obtain 42 mg of the target compound (yield 37%).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com