Heating control method for electric carburizing furnace

A technology of heating control and electric furnace, applied in the direction of non-electric variable control, temperature control, control/regulation system, etc., which can solve the problems of backward carburizing electric furnace heating control technology, affecting product quality and output, and inability to continuously adjust furnace temperature. Achieve the effects of compact structure, strong isolation and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

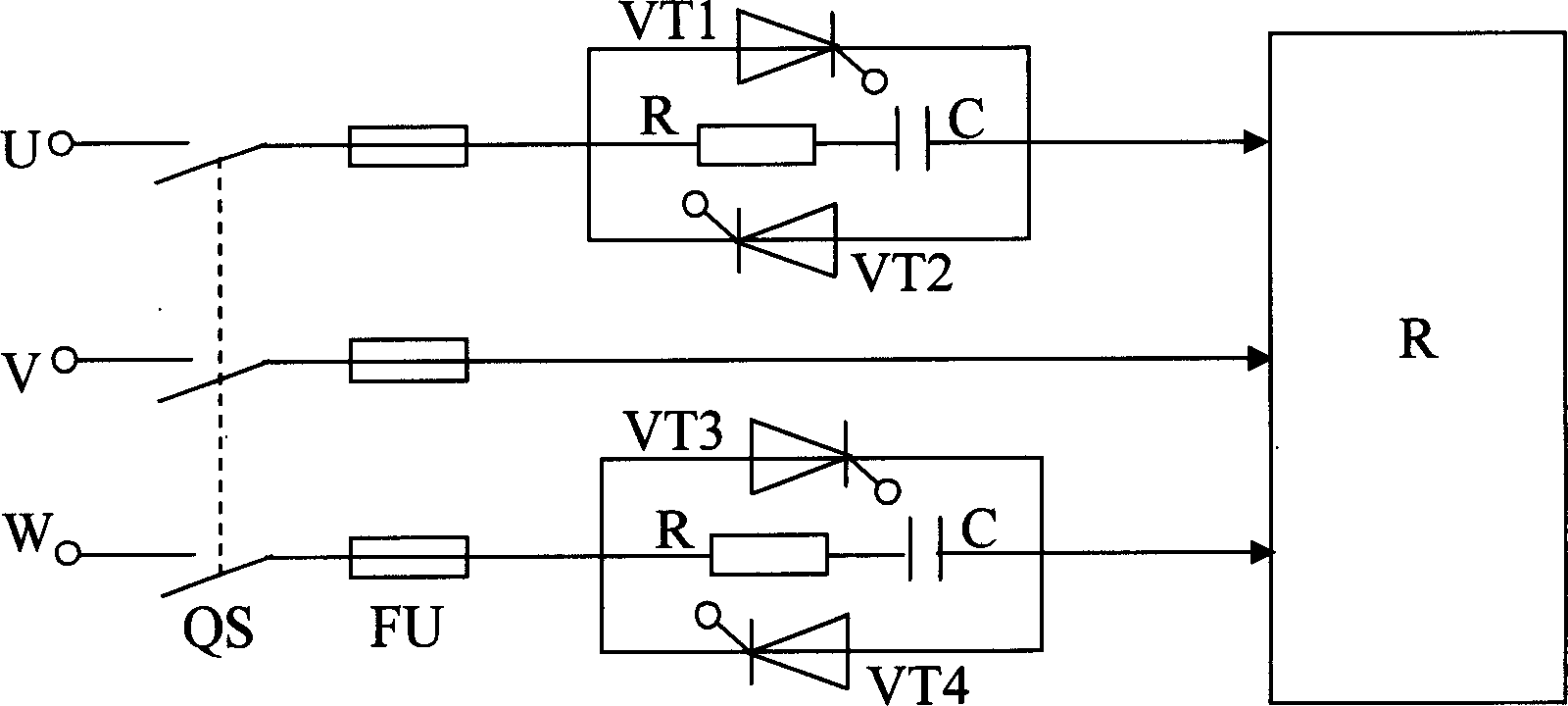

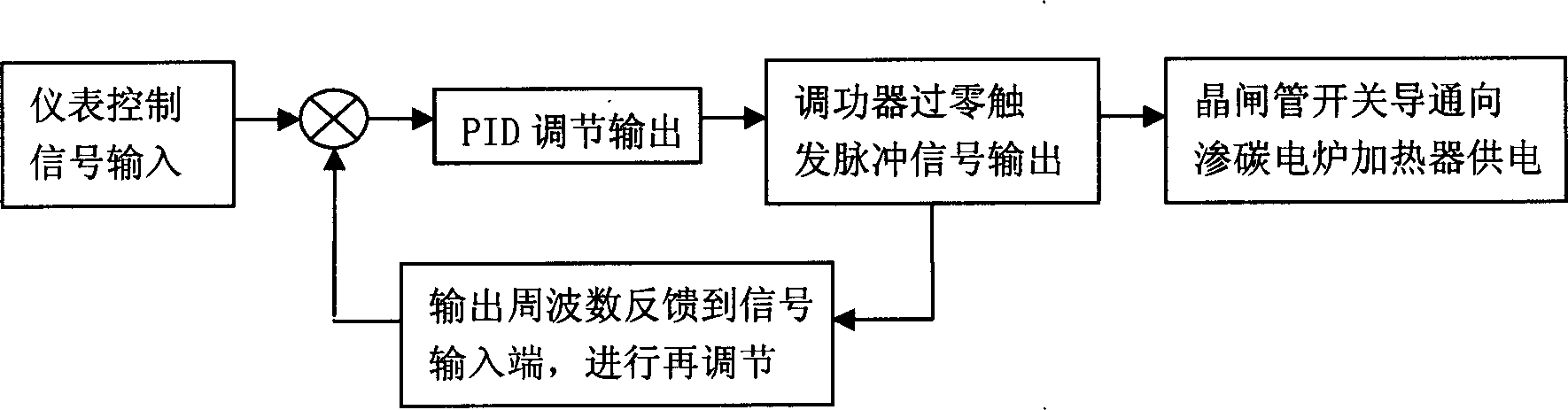

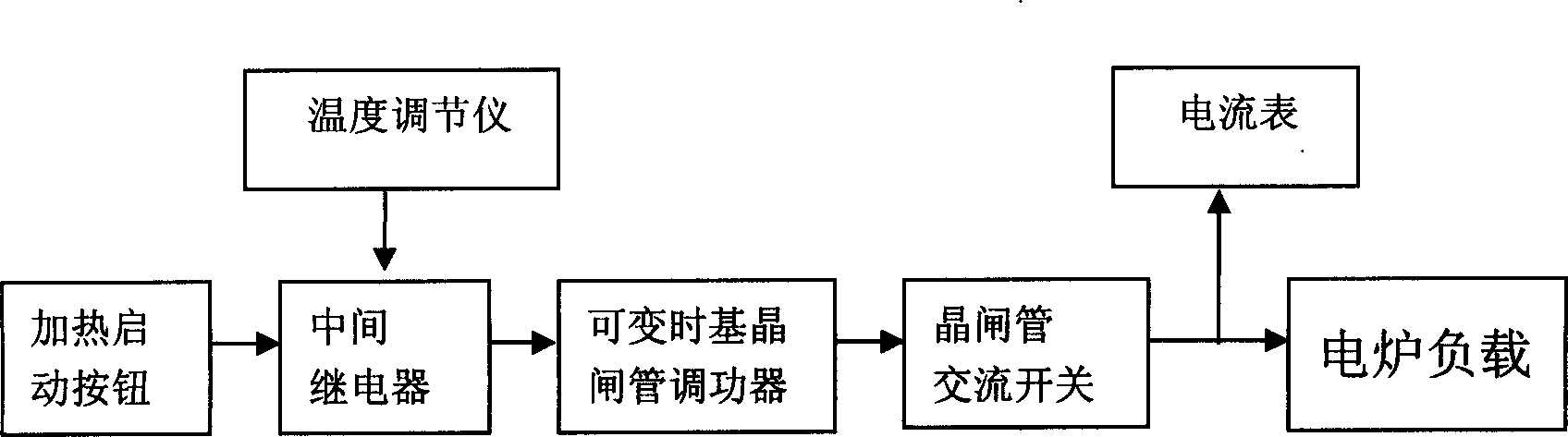

[0020] A combined and integrated thyristor variable time base power regulator is installed. The main circuit adopts three-phase control two-phase mode, and each control phase is composed of two ordinary unidirectional thyristors connected in antiparallel to form an AC non-contact switch, which is connected between the AC power supply and the electric furnace load.

[0021] The control circuit is composed of power supply, synchronous transformer, signal processing circuit, trigger circuit, etc., and the pulse transformer is replaced by a photoelectric coupling element, which has good matching and strong isolation. There is no positive or negative requirement for the connection between the instrument input signal and the actuator, and there is no wiring requirement for the connection between the controller and the main circuit thyristor switch. It has the function of component over-temperature protection and fast fuse blowout, thyristor breakdown and alarm function of phase loss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com