Laser diode array dual feedback external cavity laser

A laser diode, dual feedback technology, applied in the field of external cavity lasers, can solve the problem of inability to improve spatial characteristics, and achieve the effect of improving spatial characteristics and spectral characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

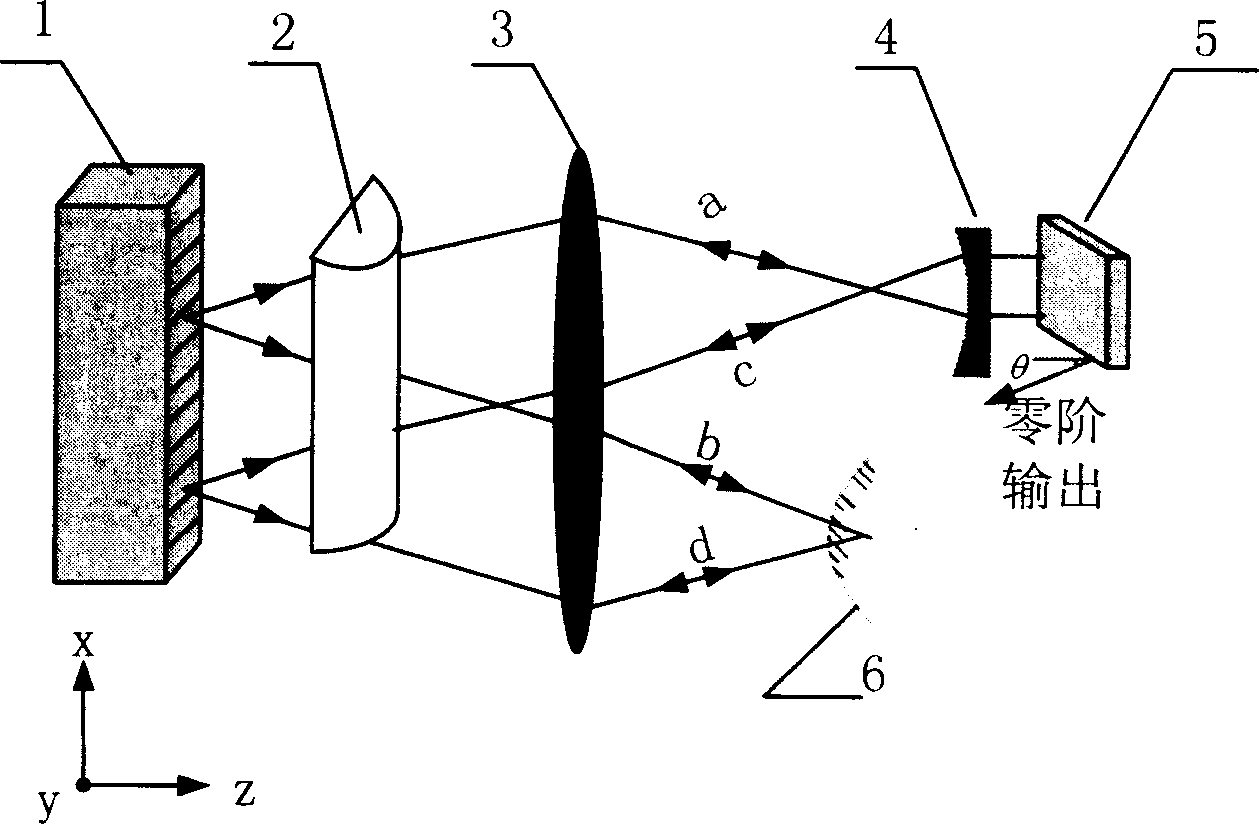

[0017] see first figure 1 , as can be seen from the figure, the laser diode array double feedback external cavity laser of the present invention includes a laser diode array 1, and a fast axis collimating mirror 2 and a lens 3 are arranged in the fast axis direction of the laser diode array 1, and in the The top behind the lens 3 is a concave lens 4 and a grating 5, and the bottom is a spherical reflector 6. The lens 3 and the spherical reflector 6 constitute a feedback cavity for a path of light propagating downward, and the lens 3 will transmit a path of light downward The light converges at the focal point of the spherical reflector 6; the lens 3, the plano-concave lens 4 and the grating 5 constitute a feedback chamber for the upwardly propagating one-way light, and the lens 3 converges the upwardly-spreading one-way light on the focal point of the concave lens 4, and passes through the concave lens After 4, the light beam is coupled to the grating 5 in parallel, where the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com