Lithium ion secondary cell

A secondary battery and lithium-ion technology, applied in secondary batteries, lithium batteries, battery electrodes, etc., can solve the problems of inability to check heat dissipation guarantee, low mobility of lithium ions, etc., and achieve the effect of excellent heat dissipation characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

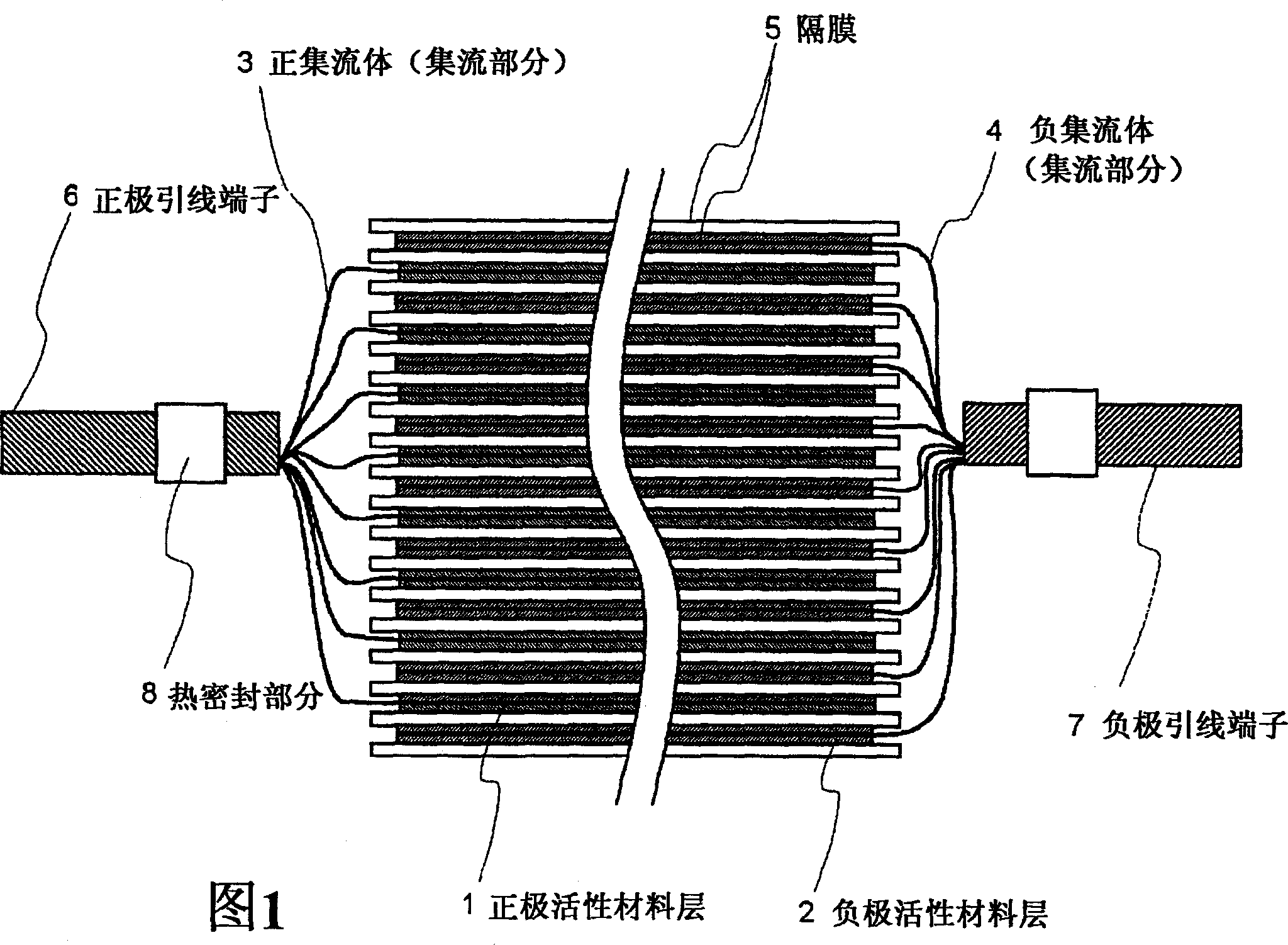

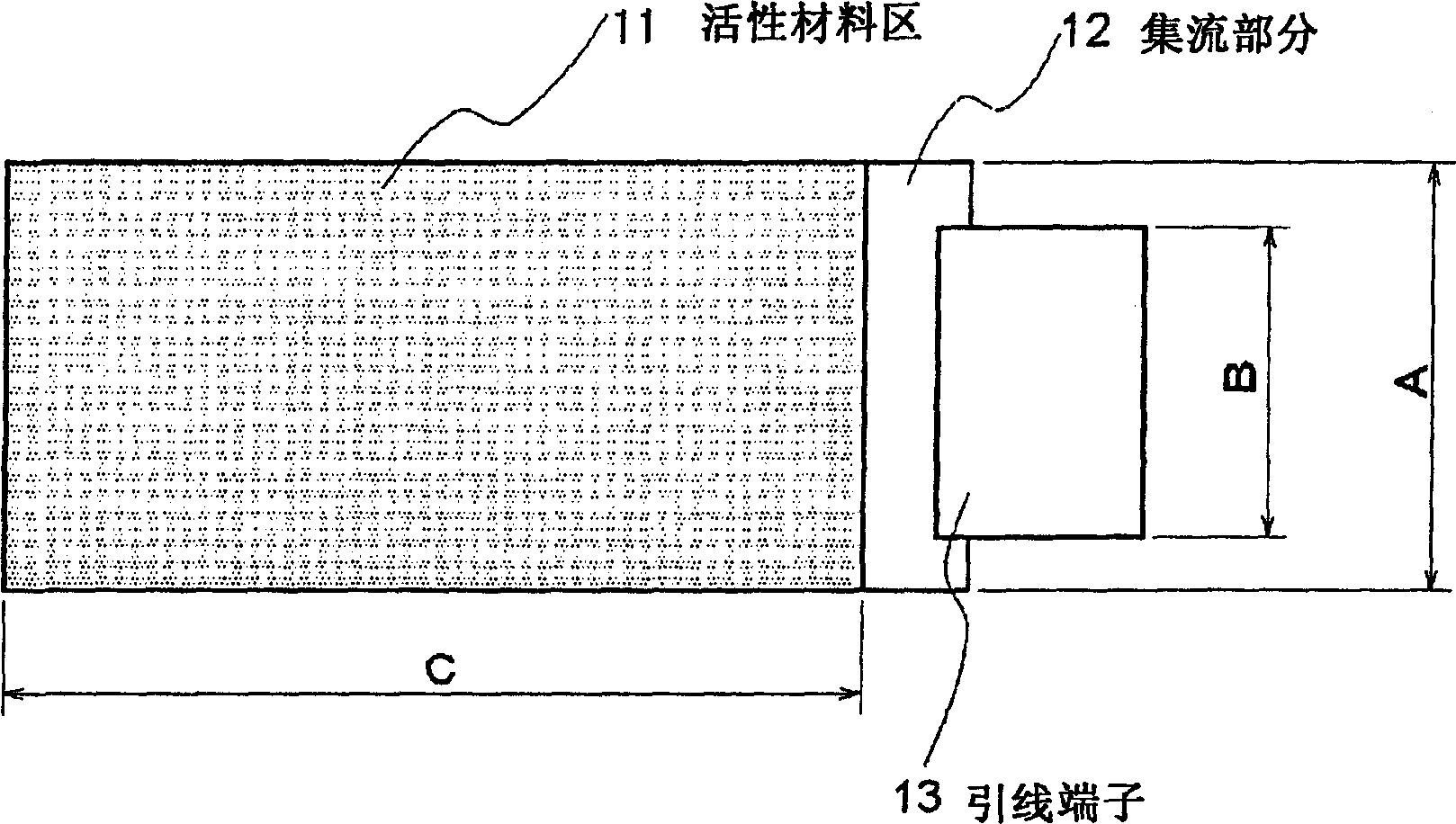

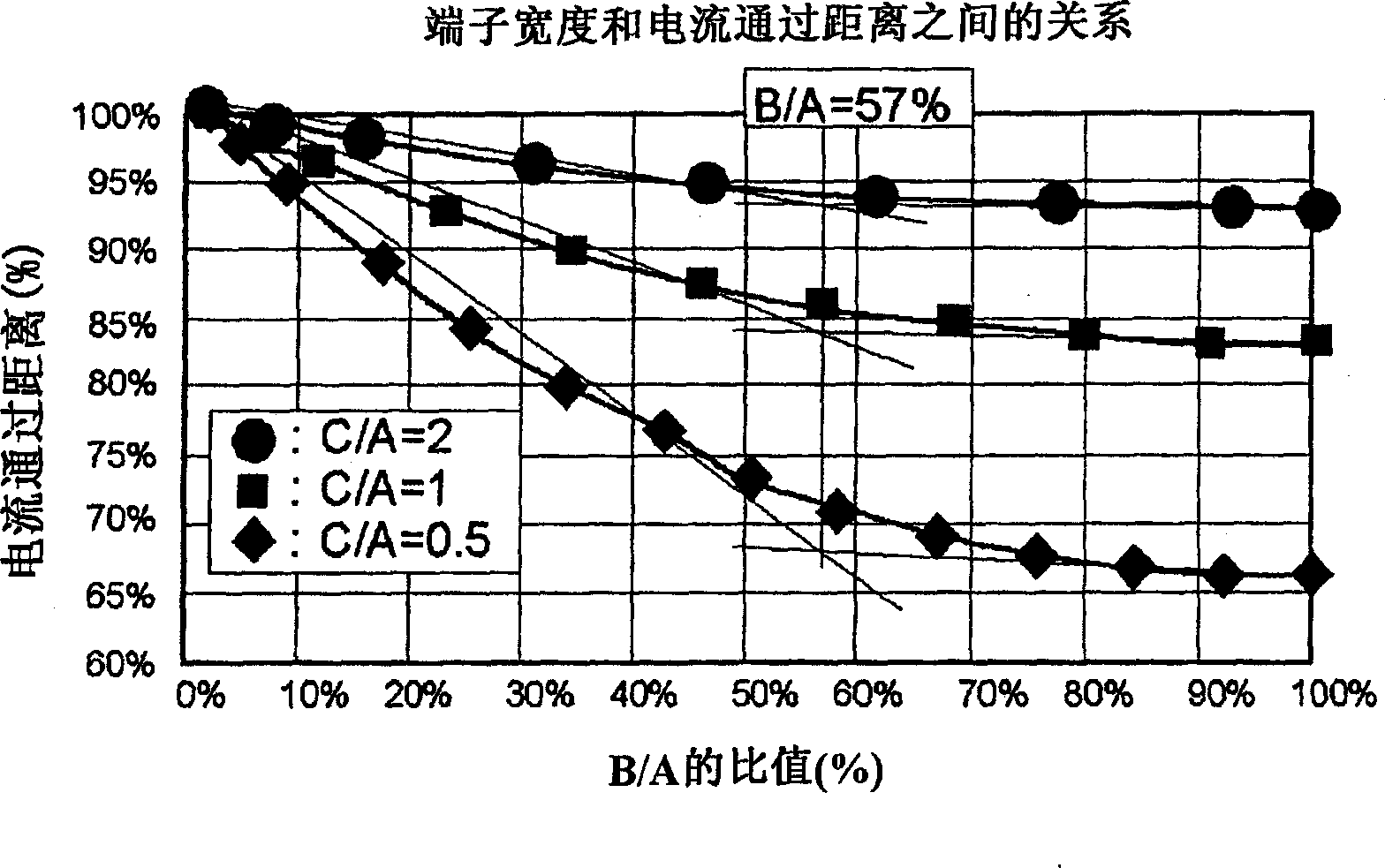

[0095] Lithium manganese oxide powder with a spinel structure with an average particle size of 5 μm, a carbon-containing conductive donor, and polyvinylidene fluoride (polyvinylidene fluoride) were mixed in a weight ratio of 90:5:5 and dispersed in N-methyl- 2-pyrrolidone (NMP) and agitated to form a slurry. The amount of NMP is adjusted so that the slurry has proper viscosity. The slurry was applied using a doctor blade onto one side of an aluminum foil having a thickness of 20 μm, which became a positive current collector. When coating, the uncovered portion (the portion where the current collector is exposed) is slightly banded. Next, it was dried in a vacuum at 100° C. for 2 hours. In a similar manner, the slurry was coated on the other surface and dried in vacuum. At this time, align both sides of the uncovered portion. A sheet coated with active material on both sides is rolled. At this time, the pressing pressure was adjusted so that the thickness of the positive e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com