Porous paste state bed reactor and reaction method

A technology of reactor and slurry bed, which is applied in porous slurry bed reactor and the reaction method belongs to the field of chemical machinery, which can solve problems such as difficult completion, achieve low consumption of reaction materials, shorten evaluation time, and uniform distribution of temperature and pressure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

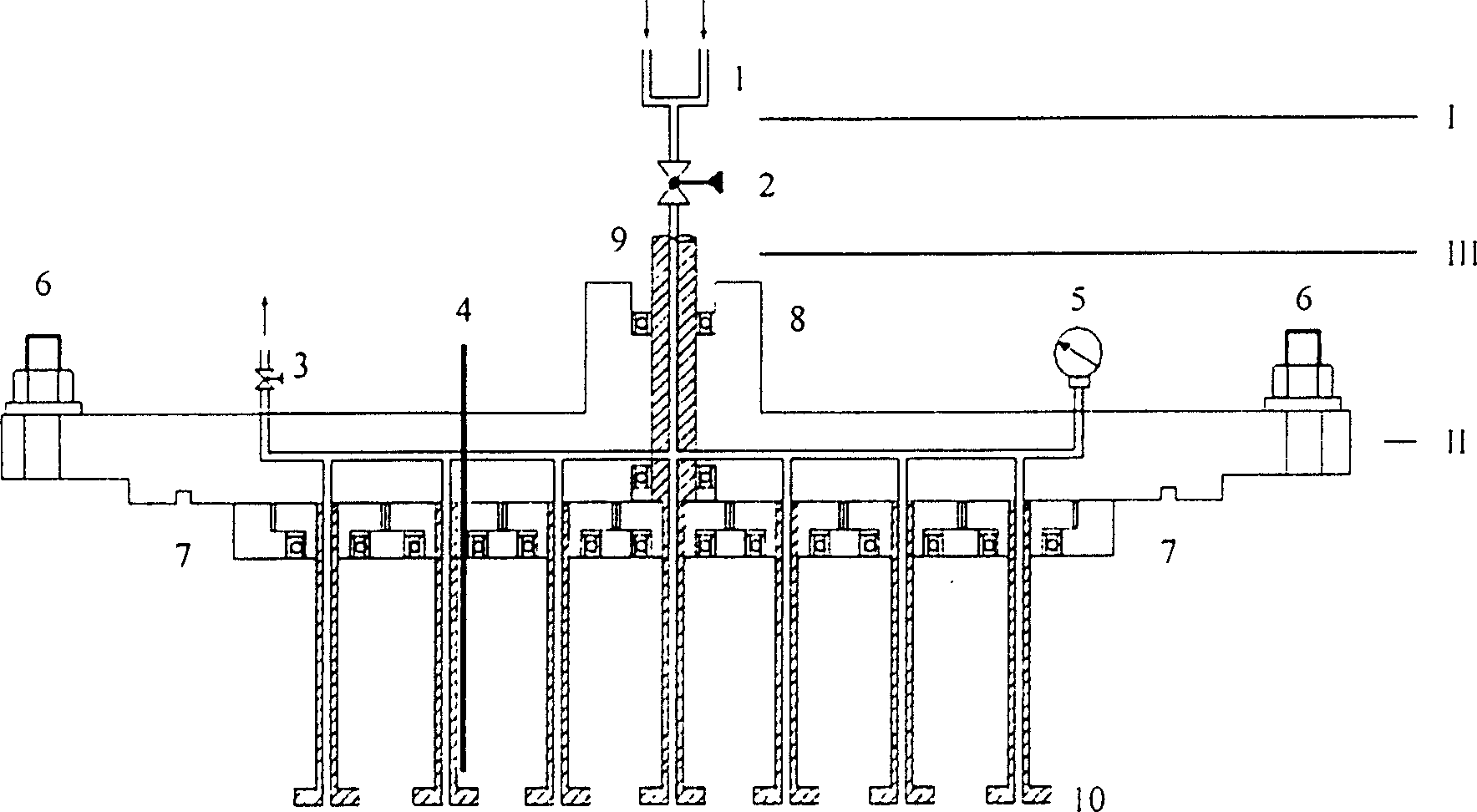

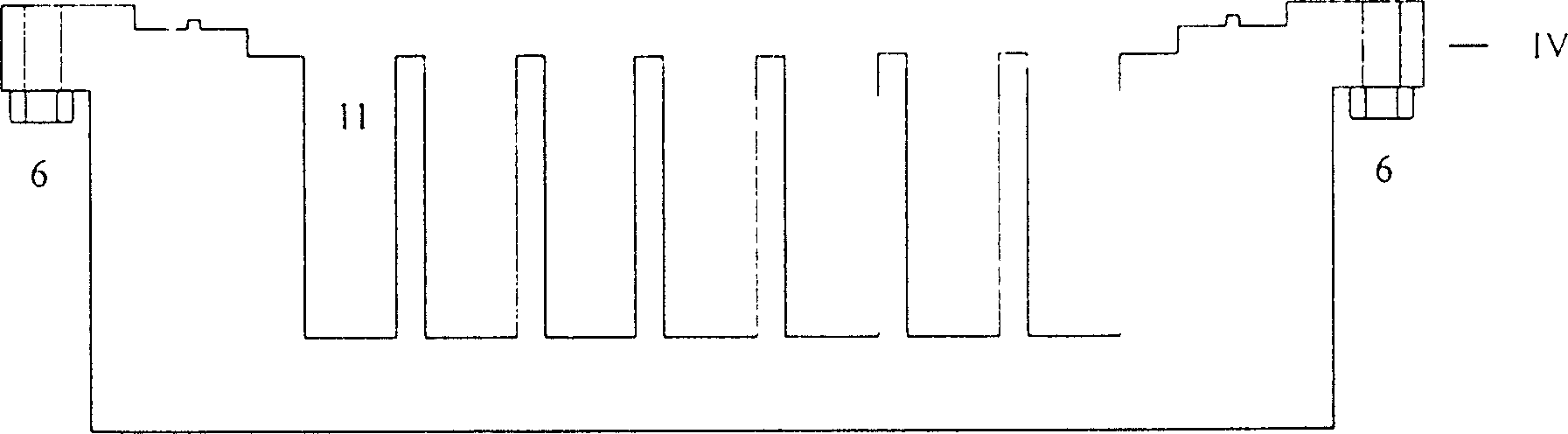

[0015] Process the reactor body IV with a 1G18Ni9Ti stainless steel material with a diameter of 30 cm and a height of 10 cm. On the reactor body IV, process 37 small hole reactors 11 with a diameter of 2 cm and a height of 8 cm. The interval between holes is 0.8 cm. The kettle cover II is made of 1G18Ni9Ti stainless steel, with a diameter of 30cm and a height of 6cm. The hollow stirring rod 10 is made of 1G18Ni9Ti stainless steel. The heating power of the electric furnace is 0.5kW. The operating temperature of the reactor is 50-220°C and the pressure is 0.1-5.0MPa.

Embodiment approach 2

[0017] Be 25cm in diameter and be 10cm in height TA2 titanium alloy material process reactor body IV, process 20 small hole reactors 11 with a diameter of 2.5cm and a height of 7.5cm according to the interval of 0.5cm; the reactor kettle cover is made of TA2 Titanium alloy material processing, diameter 25cm, height 5cm, hollow stirring rod is processed by TA2 titanium alloy material, the reaction gas is distributed to the gas delivery pipe through the spherical valve to reach each reactor hole, the gas delivery pipe is processed by stainless steel material, the inner diameter is 0.4cm, the wall thickness 0.2.5cm, heated by a heat conduction oil bath, the heating power is 1kW, the operating temperature of the reactor is 50-180°C, and the pressure is 0.1-3.0MPa.

Embodiment approach 3

[0019] Synthesis of dimethyl carbonate by methanol liquid-phase oxidative carbonylation reaction: Weigh 0.2g of each of the 37 prepared solid powder catalysts and put them into 37 reactor holes, then add 8ml of methanol respectively, cover the lid of the kettle, and tighten it to fix screw. Open the ball valve and fill with O 2 To 2.4MPa, keep for 30 minutes to check the airtightness, and then open the vent valve to discharge O 2 , and then recharge O 2 To 0.8MPa, continue to fill with CO until the total pressure is 2.4MPa, close the ball valve to completely separate each reactor hole to maintain an independent reaction system. Set the reaction temperature to 140°C, adjust the rotation speed to 700 rpm, and stop heating after 90 minutes of reaction. After the temperature in the kettle dropped to room temperature, samples were taken from each reactor hole, and the product composition was analyzed by HP6890 gas chromatograph.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com