Corn starch soaking prodn. process of adding vegetable protease

A production method, corn starch technology, applied in the field of corn starch enzymatic soaking production process, to achieve the effects of reducing energy consumption, improving production efficiency, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

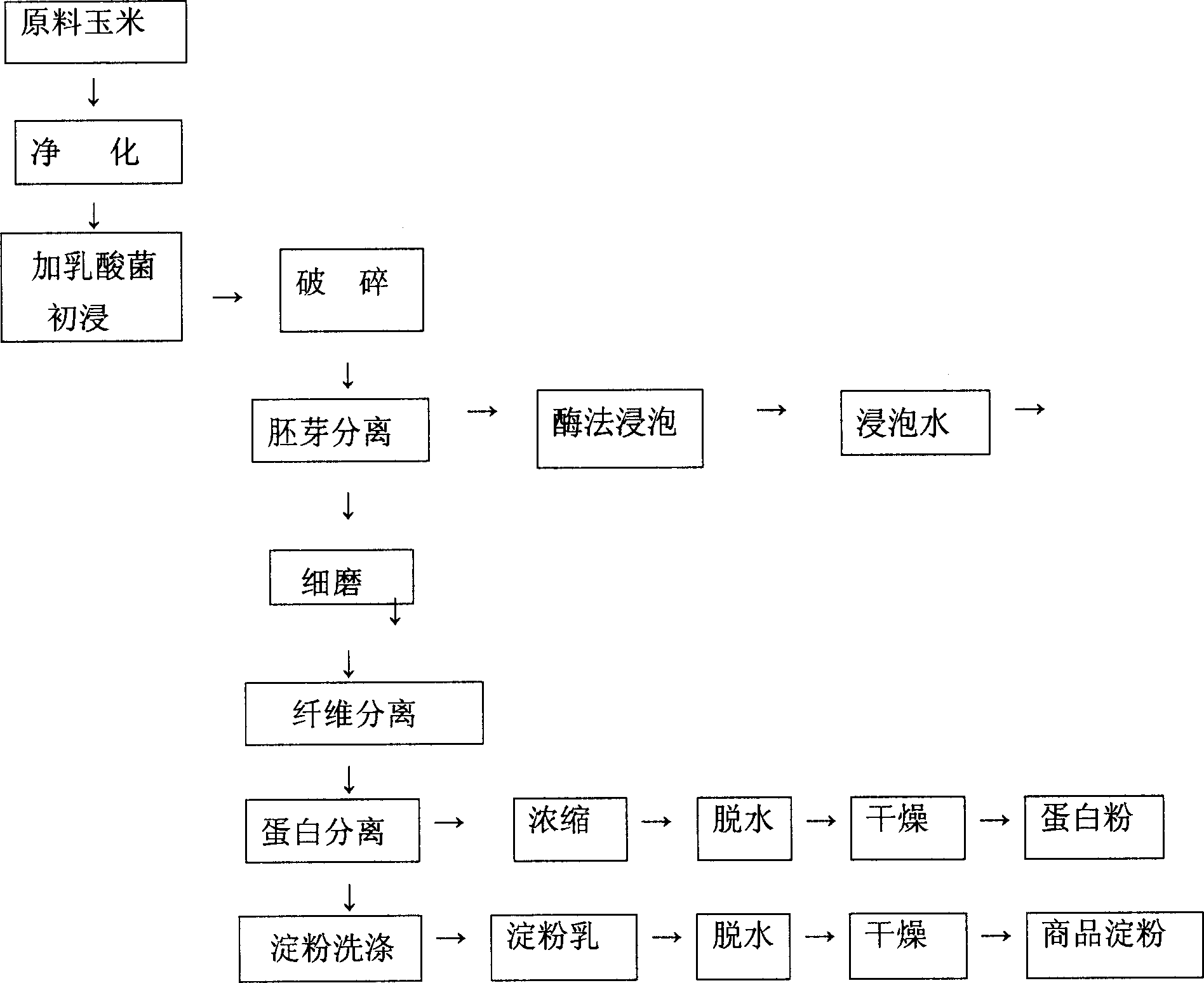

Image

Examples

Embodiment 1

[0019] Embodiment 1. When the concentration of lactic acid bacteria added to the soaking solution is 0.1%, the bromelain concentration is 0.1%, and the SO 2 When the concentration is 0.06%, the purpose of shortening the soaking time can be achieved. The soaking time is generally 23-24 hours, and the starch yield is the same as the current wet soaking production process.

Embodiment 2

[0020] Embodiment 2, when the concentration of lactic acid bacteria added to the soaking solution is 0.5%, the bromelain concentration is 0.3%, SO 2 When the concentration is 0.06%, the soaking time can be significantly shortened. The soaking time is generally 20 hours, and the starch yield can be increased by 2 percentage points compared with the current wet soaking production process.

Embodiment 3

[0021] Embodiment 3, when the concentration of lactic acid bacteria added to the soaking solution is between 0.1% and 0.5%, the concentration of bromelain is between 0.1% and 0.3%, SO 2 When the concentration is 0.06%, the soaking time is generally 20 to 14 hours, and the starch yield is basically the same as the current wet soaking production process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com