Doped rare earth element gallium oxide type fluorescent substrate material and its prepn. method

A technology of fluorescent substrates and rare earth elements, which is applied in the direction of luminescent materials, chemical instruments and methods, and climate sustainability, can solve the problems of obtaining yellow light emission, waste of raw materials, and increasing the volume of devices, and achieves a simple preparation process, The effect of small lattice mismatch and simplified preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

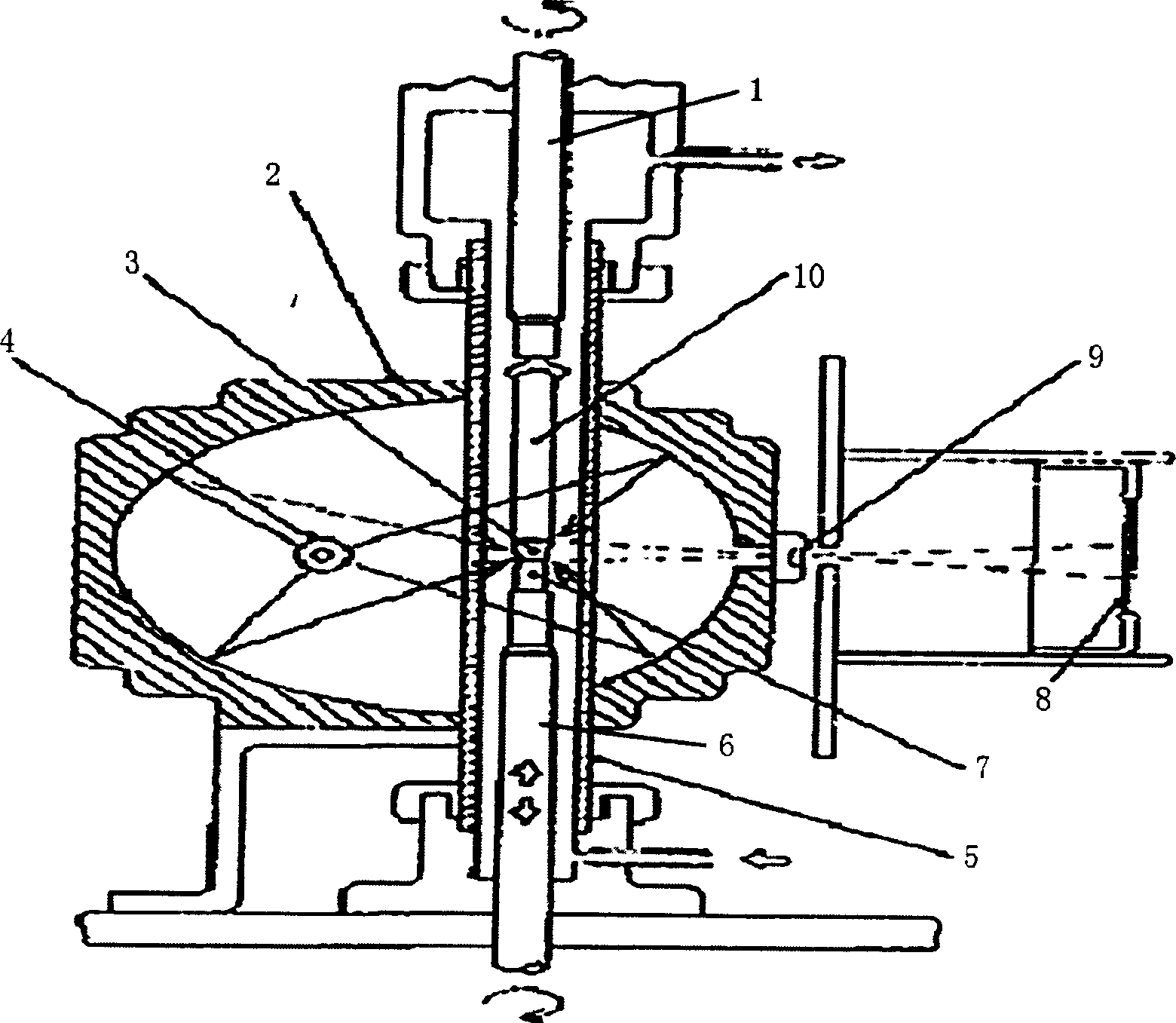

[0048] According to the above process step , weigh the dry 0.0999mol Ga 2 o 3 and 0.0002mol of CeO 2 . According to step , mix the raw materials evenly. According to step , the raw material is pressed into a raw material rod 10 under an isostatic pressure of 10-100 MPa. According to step , the raw material rod 10 was sintered at a temperature of 1450° C. for 12 hours. Install the raw material rod 10 and the a-axis seed crystal 7 in the floating zone furnace according to step . According to step , the raw material rod 10 is melted by means of infrared lamp 4 heating; the growth atmosphere is N 2 +O 2 , N / (O+N)=10%. The growth rate of the crystal is 5mm / hr, the rotational speed of the crystal is 10rpm, and the growth temperature of the crystal is 1750°C. After the crystals go through the processes of inoculation, necking, shouldering, equal necking, closing, and cooling, the growth ends. According to step put the crystal in N 2 Annealing treatment under the atmosphere...

Embodiment 2

[0050] According to embodiment one process step , take by weighing the Ga of the dry 0.099mol that purity is 99.999% 2 o 3 and 0.001mol of CeO 2 . Steps in Example 1 were repeated, and the raw material rod 10 and a-axis seed crystal 7 were installed in the floating zone furnace according to step . According to step , the raw material rod 10 is melted by means of infrared lamp 4 heating; the growth atmosphere is N 2 +O 2 , N / (O+N)=50%. The growth rate of the crystal is 5mm / hr, the rotational speed of the crystal is 10rpm, and the growth temperature of the crystal is 1750°C. After the crystals go through the processes of inoculation, necking, shouldering, equal necking, closing, and cooling, the growth ends. According to step put the crystal in N 2 Annealing treatment under the atmosphere, the annealing temperature is 1000 ℃, keep warm for 30 hours. The heating or cooling rate is 50°C / hr. The obtained crystals are processed and grown in the epitaxial growth suitable...

Embodiment 3

[0052] According to embodiment one process step , take by weighing the Ga of the dry 0.099mol that purity is 99.999% 2 o 3 and 0.002mol of CeO 2 . Steps in Example 1 were repeated, and the raw material rod 10 and a-axis seed crystal 7 were installed in the floating zone furnace according to step . According to step , the raw material rod 10 is melted by means of infrared lamp 4 heating; the growth atmosphere is N 2 +O 2 , N / (O+N)=90%. The growth rate of the crystal is 5mm / hr, the rotational speed of the crystal is 10rpm, and the growth temperature of the crystal is 1750°C. After the crystals go through the processes of inoculation, necking, shouldering, equal necking, closing, and cooling, the growth ends. According to step put the crystal in N 2 Annealing treatment under the atmosphere, the annealing temperature is 1300 ℃, keep warm for 30 hours. The heating or cooling rate is 50°C / hr. The obtained crystals are processed and grown in the epitaxial growth suitable...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com