MgIn2O4/MgAl2O4 composite substrate material and preparing method thereof

A composite substrate, mgin2o4 technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of less use, increased device volume, lattice mismatch, etc., and achieves easy operation and simple preparation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

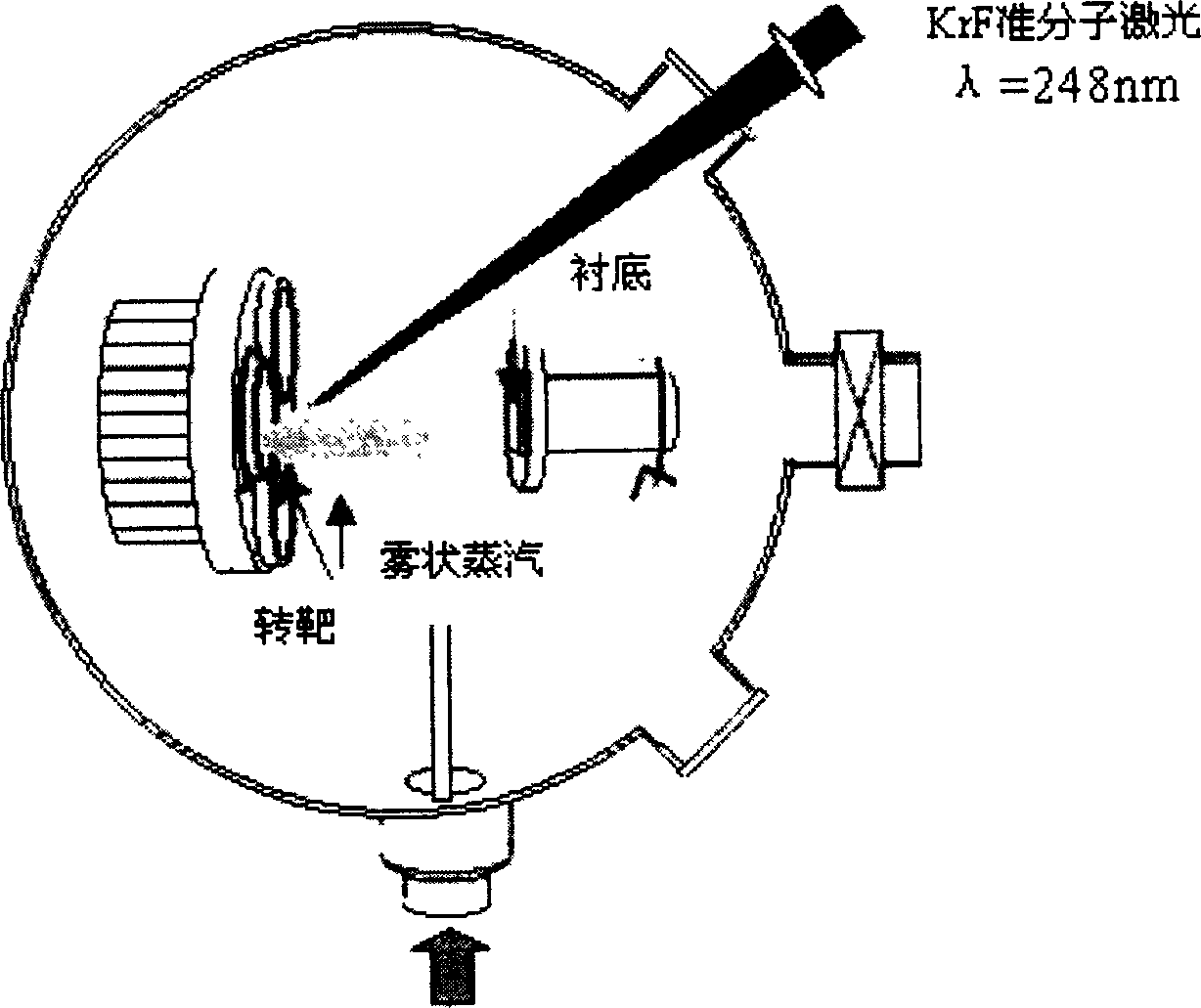

[0024] figure 1 is a schematic diagram of a pulsed laser deposition (PLD) system used in the present invention. The mechanism of the PLD method is to first pass a KrF excimer laser with a pulse width of 25-30ns (laser wavelength is 248nm) through the lens at about 10J / cm 2 The energy density concentrates the light, and irradiates the MgIn in the vacuum device through the optical window. 2 o 4Target material, after the target material absorbs the laser light, it becomes a high-temperature molten state due to electronic excitation, so that the surface of the material is evaporated and gasified, and the gaseous particles are released and diffused in the form of columns. Properly heated MgAl placed at a few centimeters 2 o 4 On a single crystal substrate, attach and accumulate to deposit MgIn 2 o 4 film.

[0025] Composite substrate material MgIn prepared by pulse laser deposition of the present invention 2 o 4 / MgAl 2 o 4 Specific

[0026] The process flow is as follo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com