Method and device of sealing-off separating device in printed substrate liquid state heat-conducting medium

A technology for printed circuit boards and heat conduction medium, applied in the directions of printed circuits, printed circuit manufacturing, electrical components, etc., can solve the problems of reducing the integrity rate of components, environmental pollution, low heat utilization efficiency, etc. The effect of high friendliness and high energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

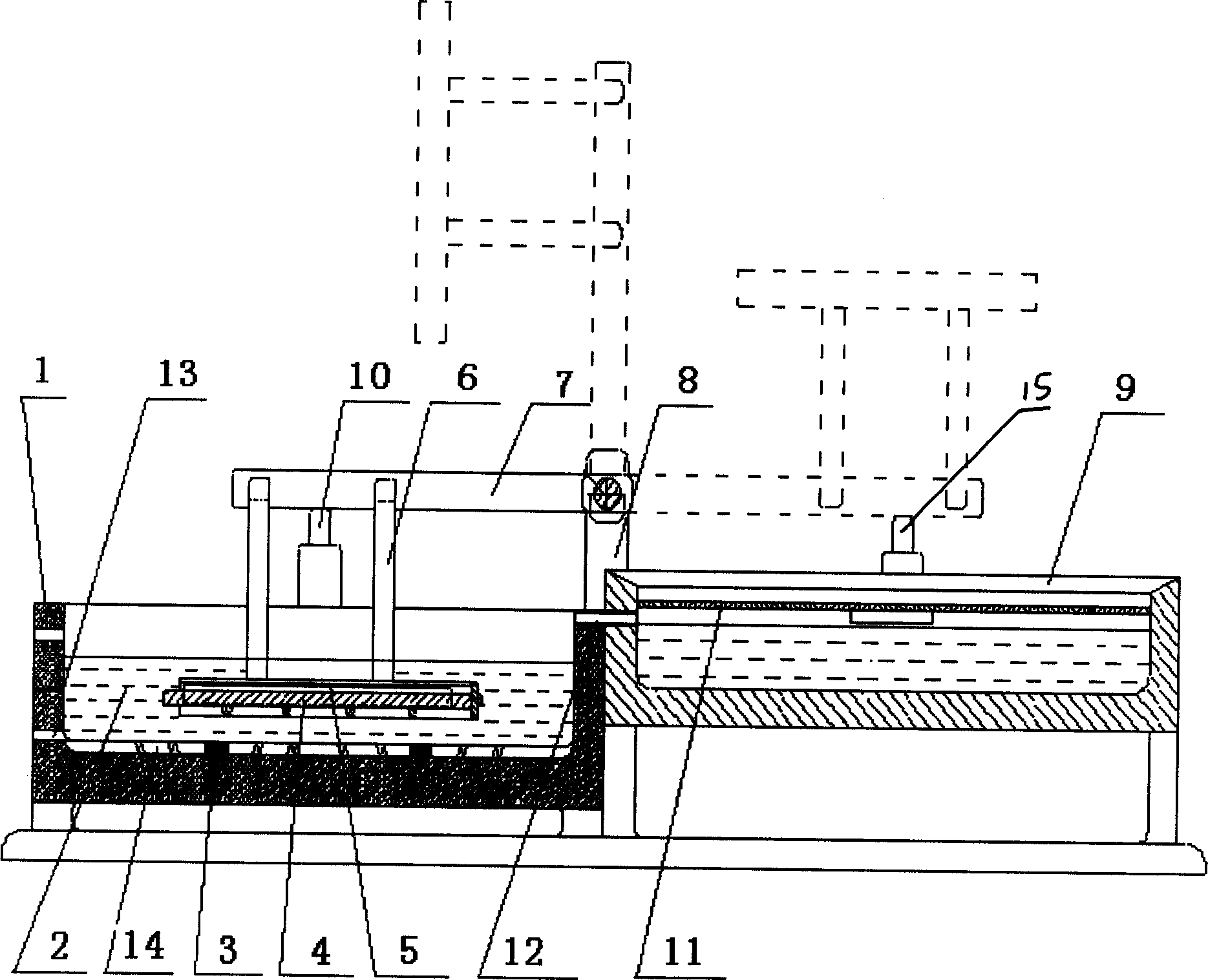

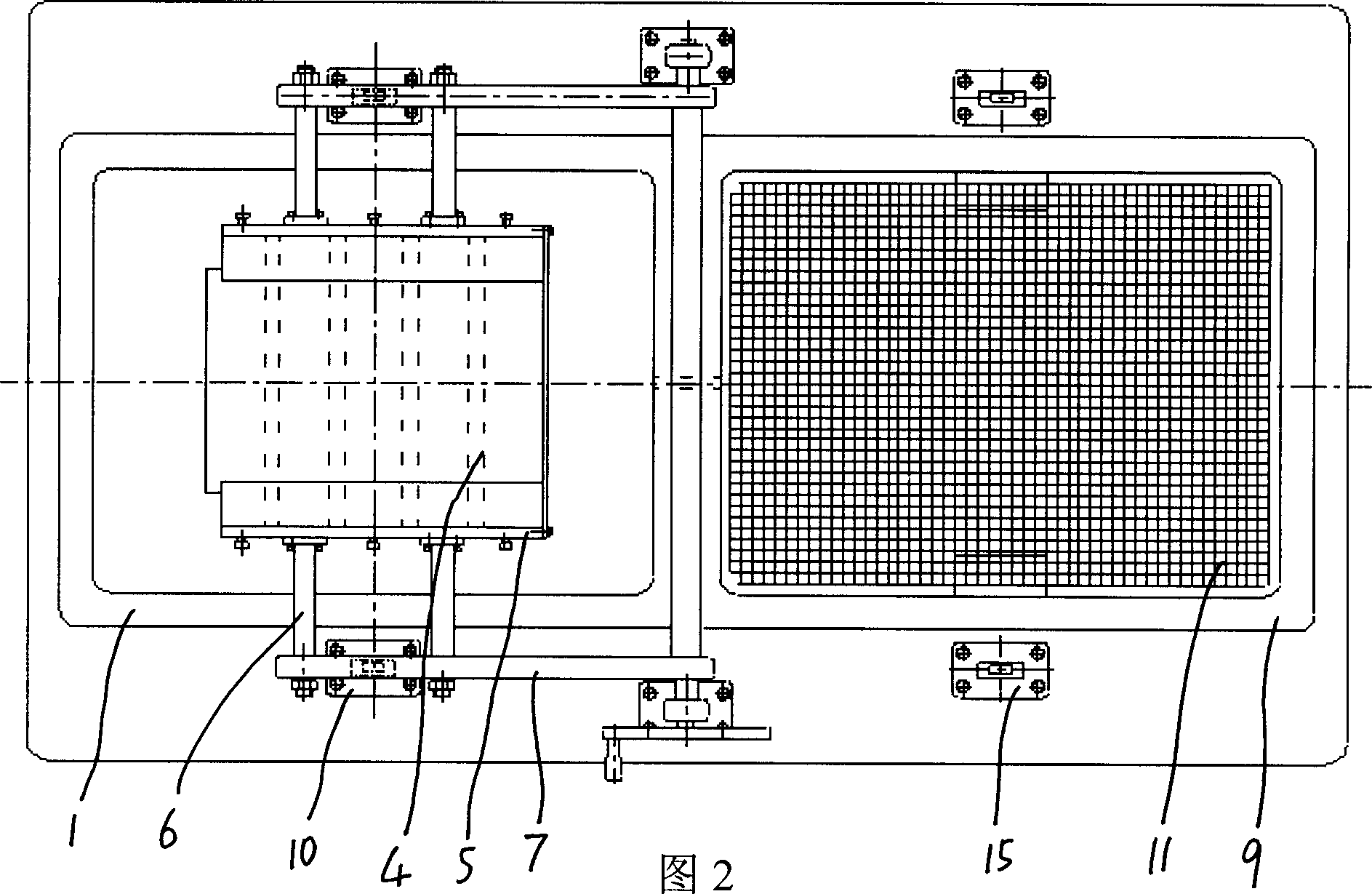

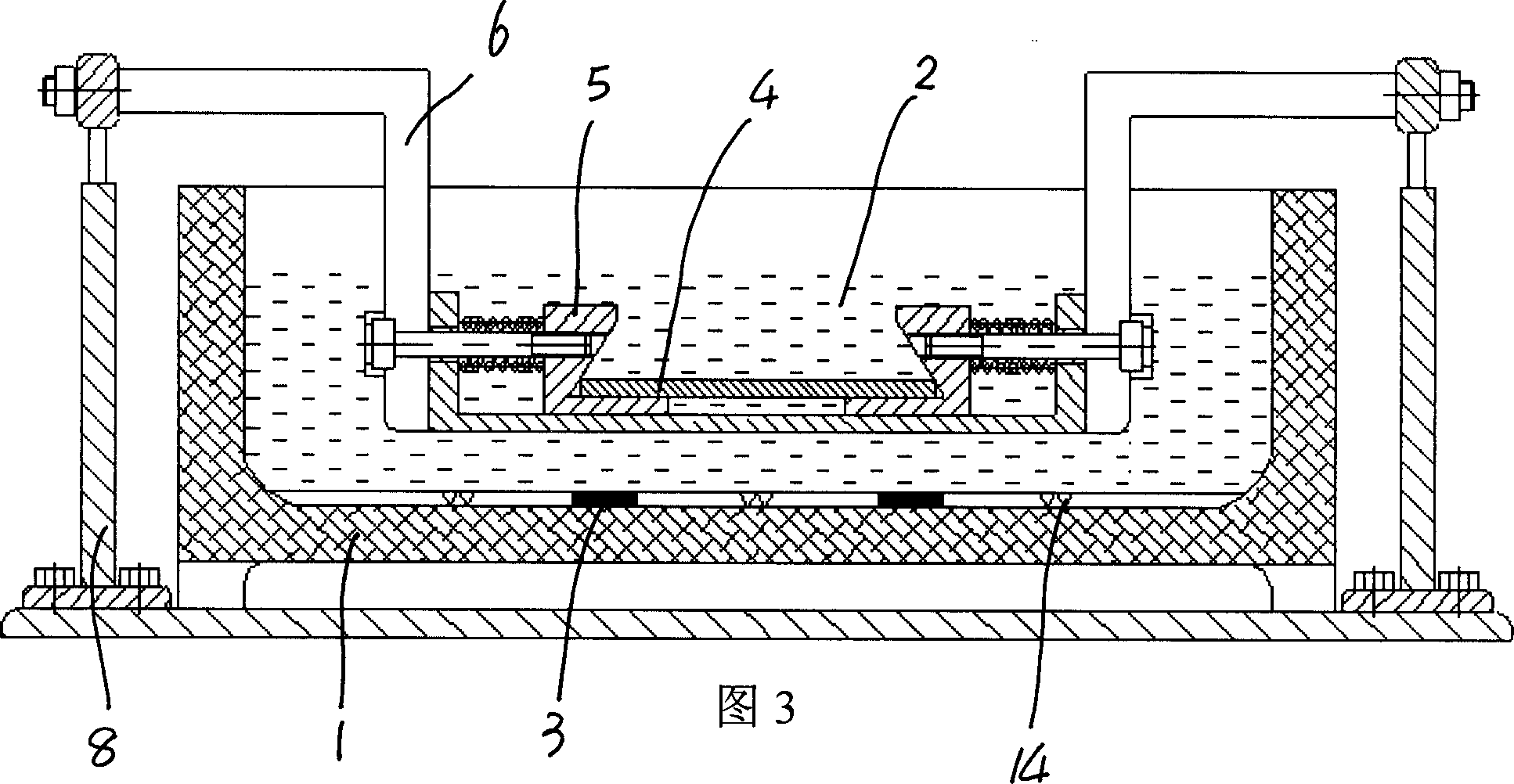

[0044] Submerge the circuit board to be processed with soldered components in the liquid heat-conducting medium, keep the liquid heat-conducting medium at the temperature at which the solder melts, and collect the solder, circuit board and components separately after the solder is melted. In the specific implementation, the circuit board should be kept Both the board and the pins of the components with solder attached to it can be completely immersed in the heat-conducting medium.

[0045] The circuit board to be processed is placed with the component facing upwards and suspended horizontally in the heat-conducting medium, and ultrasonic vibration is applied to the heat-conducting medium and / or mechanical vibration is applied to the circuit board.

[0046] The heat conduction medium is silicone oil with a boiling point of 250°C-300°C, a flash point of 300°C-350°C, and a liquid at room temperature. Silicone oil is resistant to high temperatures and has a high ignition point. It ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling point | aaaaa | aaaaa |

| Flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com