Solidified silicon rubber combination and producing method for compound molding object of liquid crystal polymer and silicon rubber

A silicone rubber composition, liquid crystal polymer technology, applied in chemical instruments and methods, liquid crystal materials, synthetic resin layered products, etc. problem, to achieve the effect of good transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

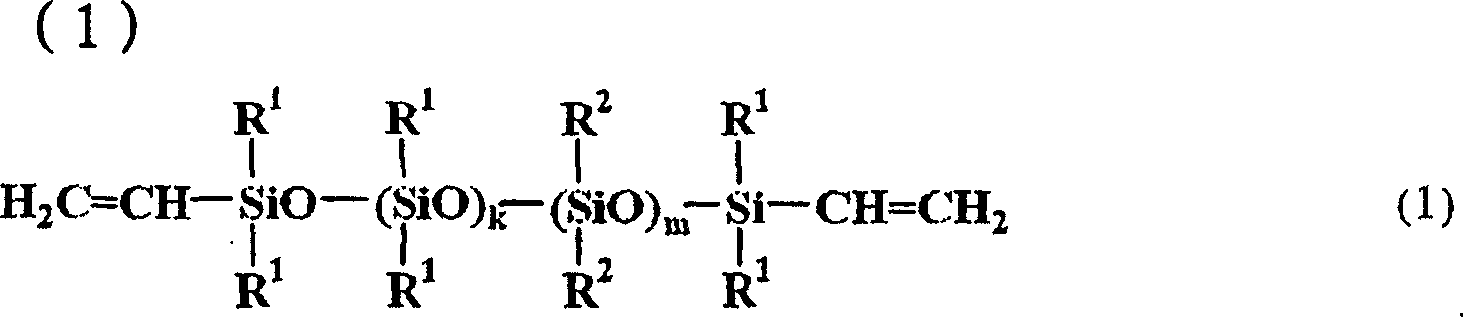

[0081] In 50 parts of polysiloxane (VF) represented by following formula (i).

[0082] [chemical 13]

[0083]

[0084] Joined by SiO 2 Unit 50 mol%, (CH 3 ) 3 SiO 0.5 Unit 42.5 mol% and Vi 3 SiO 0.5 50 parts of vinylmethylsiloxane (VMQ) with a resin structure consisting of 7.5 mol% of units, and the amount of SiH groups is 1.5 times the molar amount of the total amount of vinyl groups in the above-mentioned (VF) and (VMQ) components. Formula (ii)

[0085] [chemical 14]

[0086]

[0087] 0.05 part of octanol-modified solution of organohydrogenpolysiloxane and chloroplatinic acid, 5-ethyl-2-(2-hydroxyl-1,1-dimethylethyl)-5-(hydroxymethyl )-1,3-dioxane diacrylate (trade name: Kayarad R-604, Nippon Kayaku) 1.0 part to prepare a silicone rubber composition. The composition was thermoformed at 150° C. / 4 hr to form a cured product, and the tensile strength, hardness (measured using a type A spring testing machine) and elongation were measured in accordance with JIS K63...

Embodiment 2

[0089] Except that the R-604 used in Example 1 was changed to 2-acrylic acid (octahydro-4,7-methane-1H-indenyl) bis(methylene) ester (trade name: カヤラツド R-684, Nippon Kayaku Except that, a silicone rubber composition was prepared using the same composition as in Example 1 to form a cured product, and the results measured in the same manner as in Example 1 are shown in Table 1.

Embodiment 3

[0091] Except that the R-604 used in Example 1 was changed to lauryl acrylate, a silicone rubber composition was prepared with the same composition as in Example 1, and a cured product was formed. The results measured in the same manner as in Example 1 are shown in Table 1. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com