Composite geotextile for civil structure

A composite geotextile and civil engineering technology, which is applied in the direction of braids, textiles, papermaking, road construction reinforcements, etc., can solve the problem that it is difficult to meet high-standard road engineering requirements, affect the overall performance of composite geotextiles, and shorten the service life of the overlay and other problems, to achieve the effect of avoiding water and soil loss, enhancing filtration and barrier, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

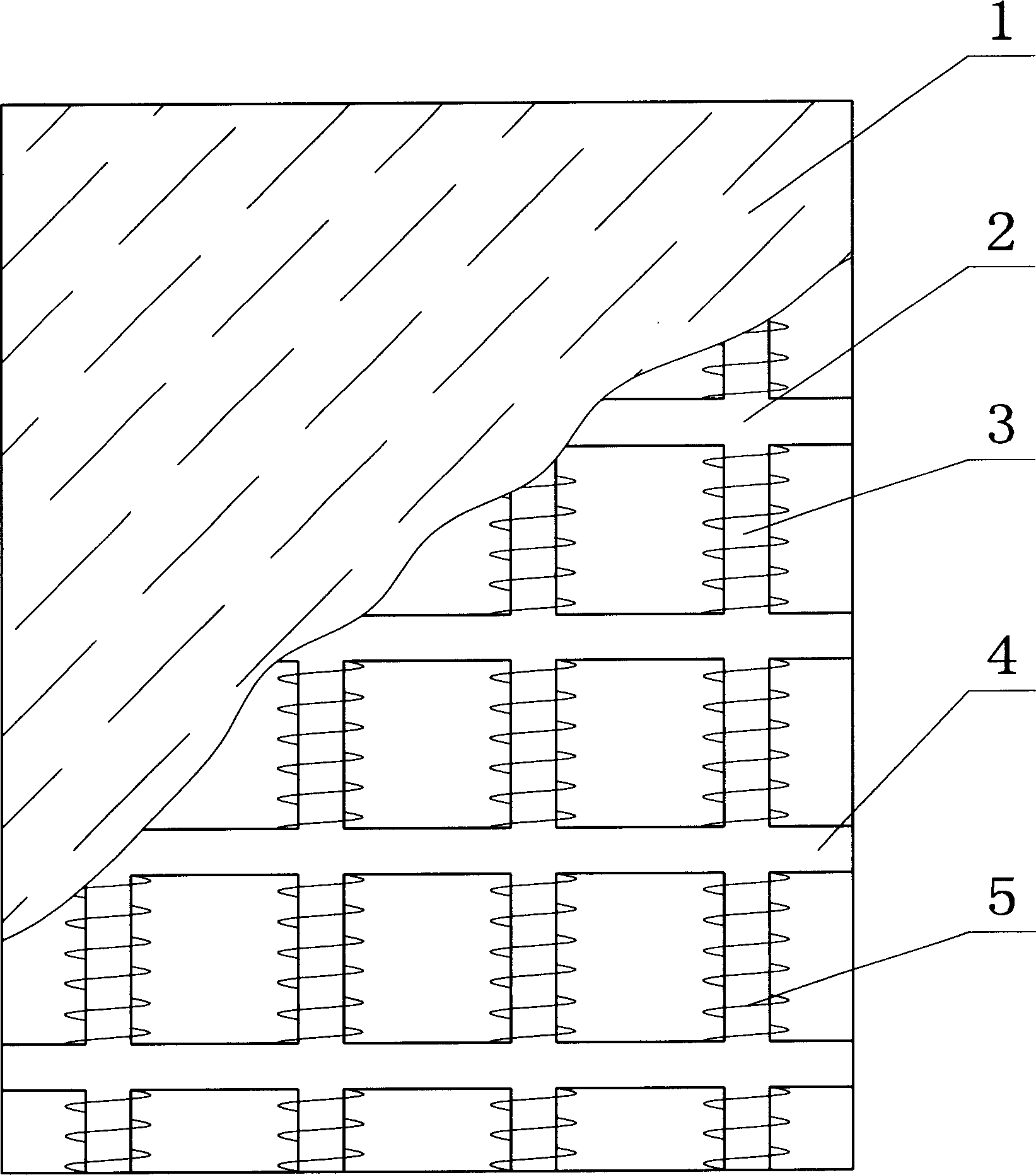

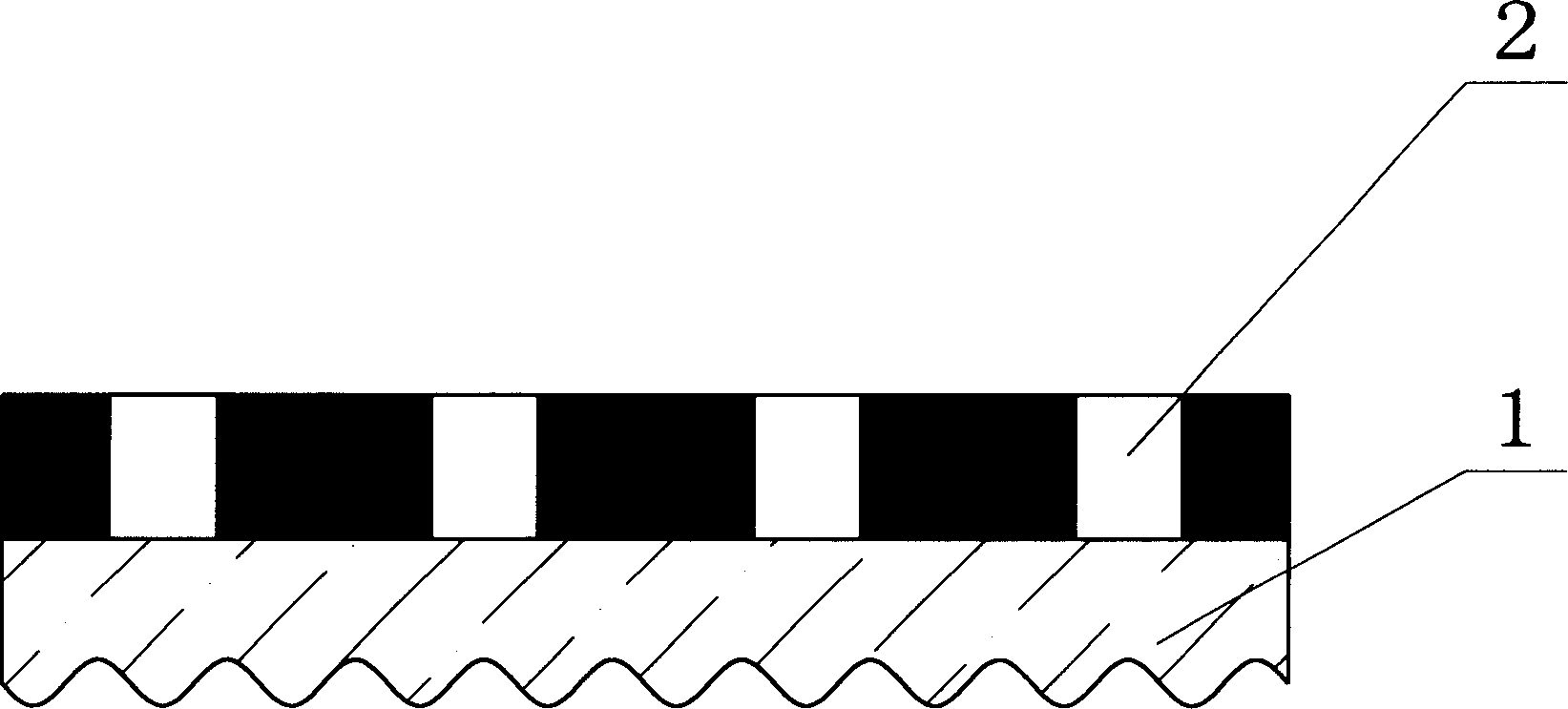

[0023] The grid composite geotextile in this embodiment includes a layer of singeing geotextile (1) and a layer of reinforced grid (2), and the reinforced grid (2) is made of glass fiber tow through the warp knitting process on the singeing geotextile (2) The surface forms a grid structure, the warp tow is woven on the surface of the geotextile, and the weft tow is woven and fixed on the surface of the geotextile only at the intersection with the warp tow to form a whole. The singeing geotextile (1) is made by singeing one surface of the geotextile. The surface of the singeing geotextile (1) is relatively rough after singeing, and it is not easy to slide during the construction process, so that the grid composite geotextile The cloth is relatively flat during the paving process. The reinforcement grid (2) is made of nylon fiber filament warp, and the reinforcement grid (2) is a grid structure composed of a set of warp threads (3) and a set of weft threads (4); the geotextile i...

Embodiment 2

[0026]The grid composite geotextile in this example includes a layer of singeing geotextile (1) and a layer of reinforced grid (2), and the reinforced grid (2) is made of nylon fiber tow through the warp knitting process (2) The surface forms a grid structure, the warp tow is woven on the surface of the geotextile, and the weft tow is woven and fixed on the surface of the geotextile only at the intersection with the warp tow to form a whole. The singeing geotextile (1) has a rough surface after singeing, and it is not easy to slide during the construction process, so that the grid composite geotextile is relatively flat during the paving process. The reinforcement grid (2) is made of glass fiber filament warp, and the reinforcement grid (2) is a grid structure composed of four sets of warp threads (3) and four sets of weft threads (4); the geotextile is made of polyester filament fibers non-woven fabric.

[0027] During road construction, first compact the roadbed, pave and f...

Embodiment 3

[0029] The grid composite geotextile in this embodiment includes a layer of singeing geotextile (1) and a layer of reinforced grid (2), and the reinforced grid (2) is made of polypropylene fiber tow through a warp knitting process (2) The surface forms a grid structure, the warp tow is woven on the surface of the geotextile, and the weft tow is woven and fixed on the surface of the geotextile only at the intersection with the warp tow to form a whole. The singeing geotextile (1) has a rough surface after singeing, and it is not easy to slide during the construction process, so that the grid composite geotextile is relatively flat during the paving process. The reinforcement grid (2) is made of glass fiber filament warp, and the reinforcement grid (2) is a grid structure composed of two sets of warp threads (3) and two sets of weft threads (4); the geotextile is made of polyester filament fibers non-woven fabric.

[0030] During road construction, first compact the roadbed, pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com