Insulating method and structure for workshop operating side and inner side of external wall

A technology for operating surfaces and exterior walls, applied in building structures, building components, building insulation materials, etc., can solve problems such as building corrosion, hygroscopicity, damage to insulation, etc., to ensure personal safety and corporate property safety, insulation, etc. Safe and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

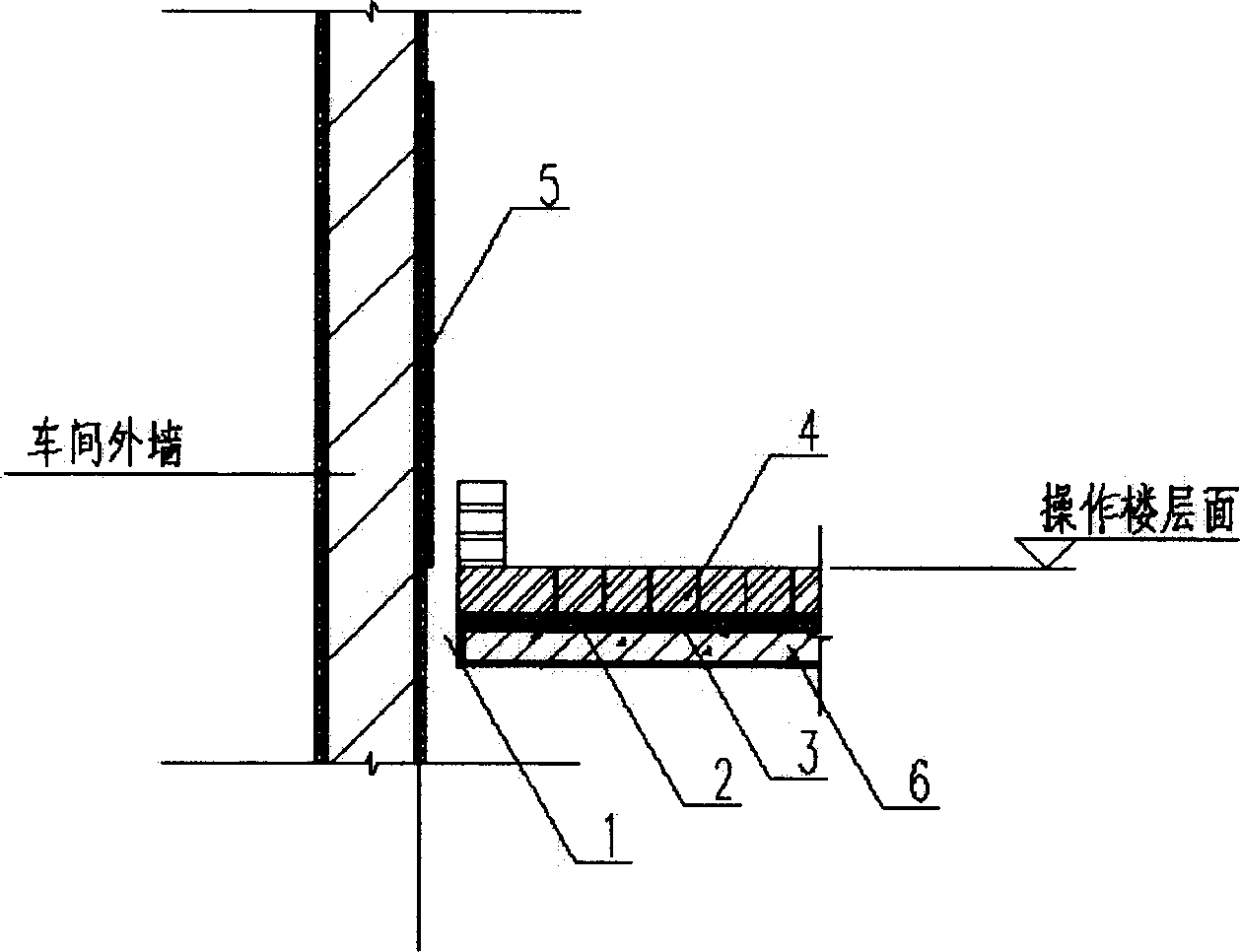

[0011] Embodiment of the present invention: first make the cast-in-place reinforced concrete operating floor slab 6 in the factory building, make it disengage from the outer wall, form an air insulation joint 1 with a width of 100mm, and place it on the cast-in-situ reinforced concrete operating floor slab 6 Make one deck 20mm thick, 1: 3 cement mortar leveling layer 2, coat one deck chlorosulfonated rubber coating waterproof insulation layer 3 on the surface of cement mortar leveling layer 2, chlorosulfonated rubber coating can directly adopt the finished product sold on the market, Then paste an acid-resistant clinker brick insulation surface layer 4 with a thickness of 113 mm on the surface of the waterproof insulation layer 3; in order to prevent the moving tools and equipment on the operation surface from directly contacting the outer wall, the acid-resistant clinker brick insulation surface layer at the end of the floor 6 on the operation floor 4 Turn up 215mm to form a r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com