Integral impacting type composite canister cover

A composite material film and main material technology, which is applied in the field of integral breakthrough composite material film cover, can solve the problems of decreased overall strength, low pressure bearing capacity, complicated process, etc., and achieves the effects of rapid response, simple structure and simple production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

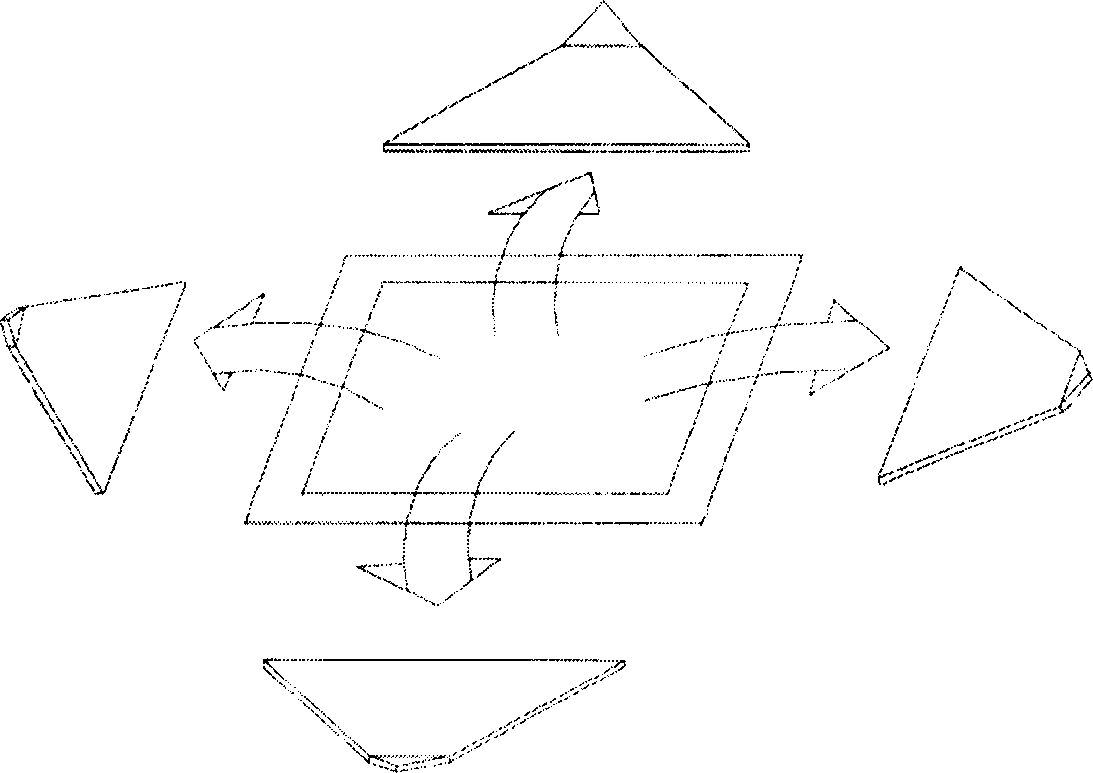

[0021] This embodiment is a manufacturing process of a film cover. The film cover is formed by hand lay-up + compression molding process, and the film cover is completed after three times of molding and curing. According to the design plan, the forming mold adopts the form of upper and lower molds, and the molds are as follows: Figure 4 , 5 As shown, one side of the lower mold has a bump for prefabricated scoring on its circumference, and the other side is a smooth flat plate.

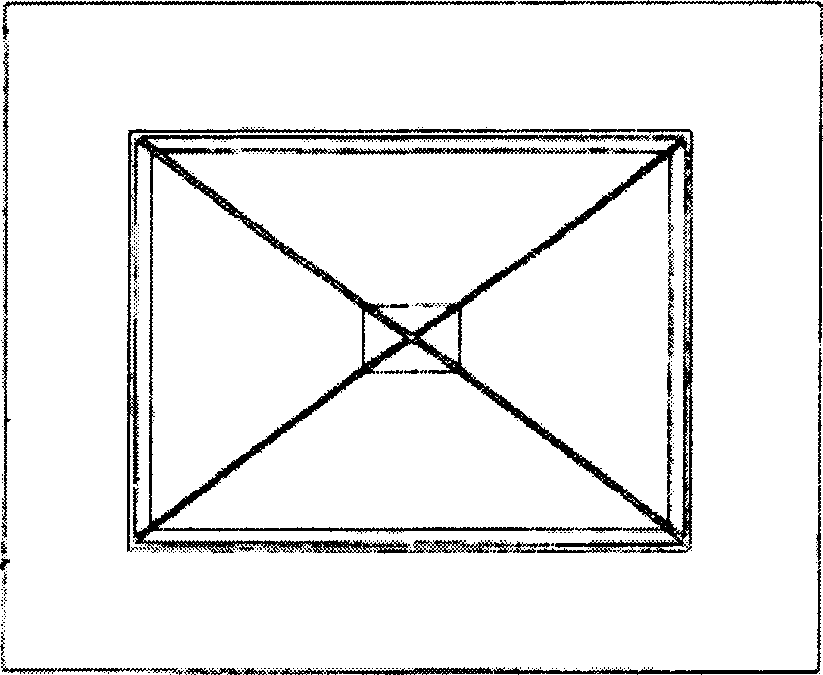

[0022] Film cover structure

[0023] 1. The main body and frame of the film cover

[0024] It is composed of several layers of 0.2 plain woven glass cloth and epoxy resin, and the laminate is [(0°90°)(±45°)(0°90°)(±45°)] quasi-isotropic symmetrical structure ;

[0025] 2. Structural form of weak area

[0026] The main body and the frame are directly glued together, which is a circle of glue layer, and 1-3 layers of 0.1 plain weave glass cloth strips are pasted on the upper and lower surfaces, an...

Embodiment 2

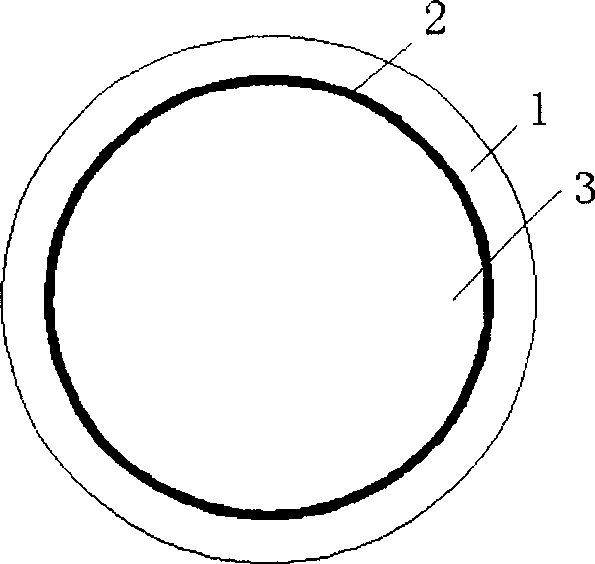

[0062] This embodiment is a specific process of a film cover burst test. Test device such as Image 6 shown. Install the film cover on the test cylinder as required, turn on the air compressor, turn off the air compressor after the pressure reaches 0.8MPa, open the inlet valve to slowly charge the pressure and carefully observe the deformation of the film cover. After charging to a certain pressure, keep it for a period of time, observe whether the membrane cover has any sound, whether there is delamination, and at the same time observe whether the reading of the pressure gauge drops during the pressure holding process, and then unload it to 0.00MPa, and observe whether the membrane cover has residual deformation , for damage. Repeat the above process to observe the deformation of the film cover and the residual deformation after unloading. After it is confirmed that there is no damage and the airtightness is good, the membrane cover will be broken through the test. Inflat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com