Safety monitoring mechanism for wafer technique platform

A safety monitoring and process technology, applied in the fields of semiconductor/solid-state device manufacturing, instruments, electrical components, etc., can solve the problems of parts aging, wear, production and assembly, and increased wafer process defect rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

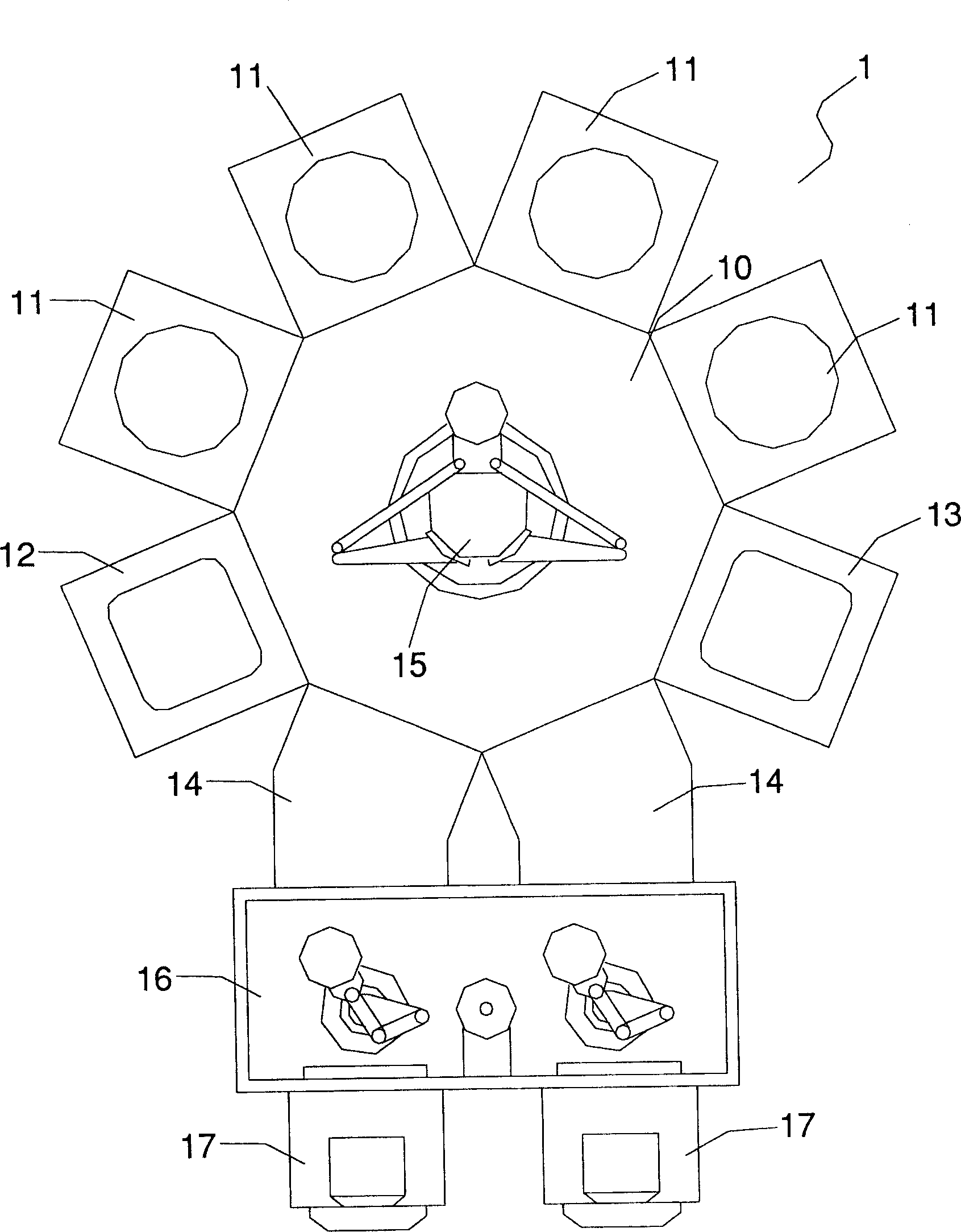

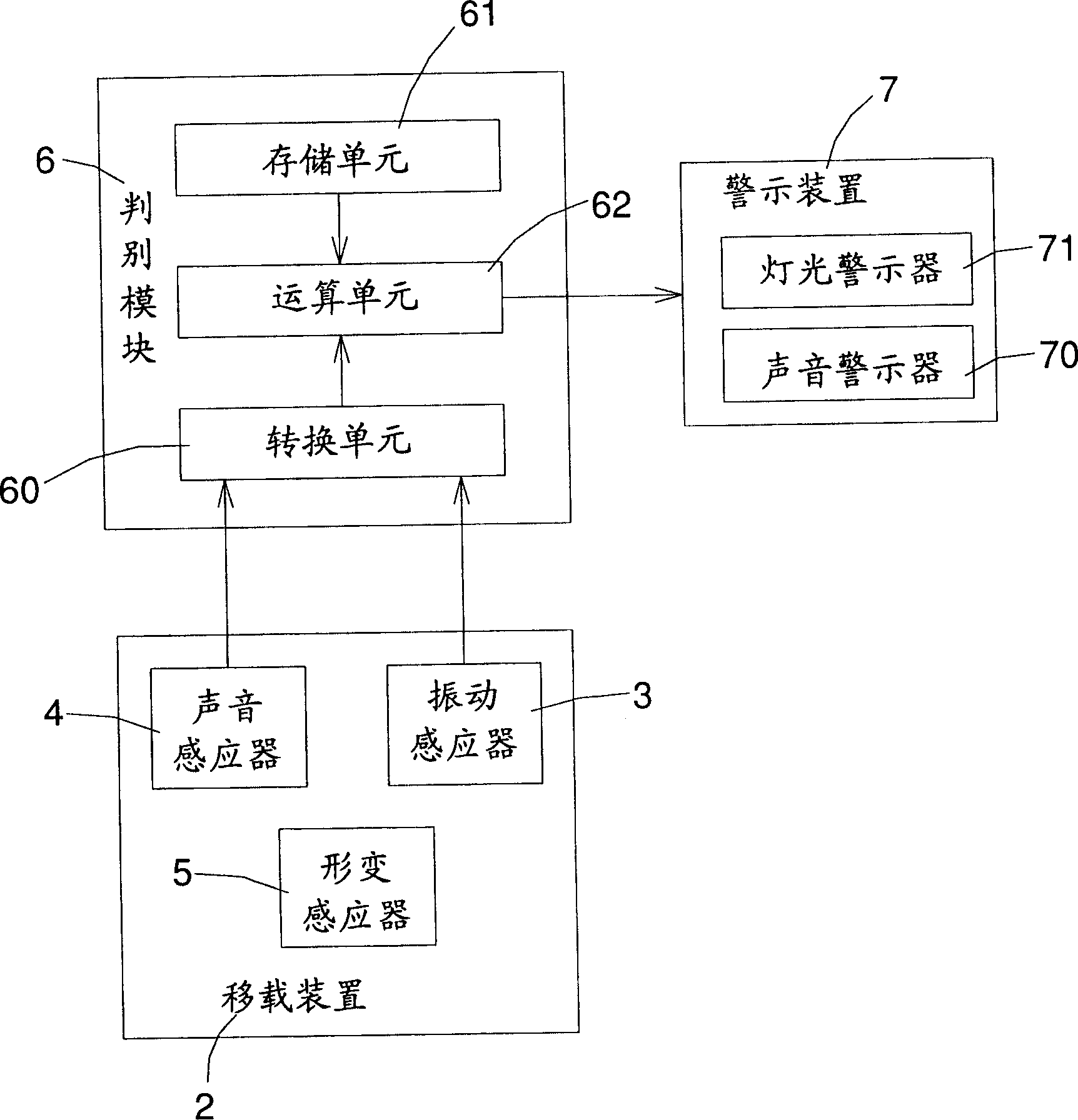

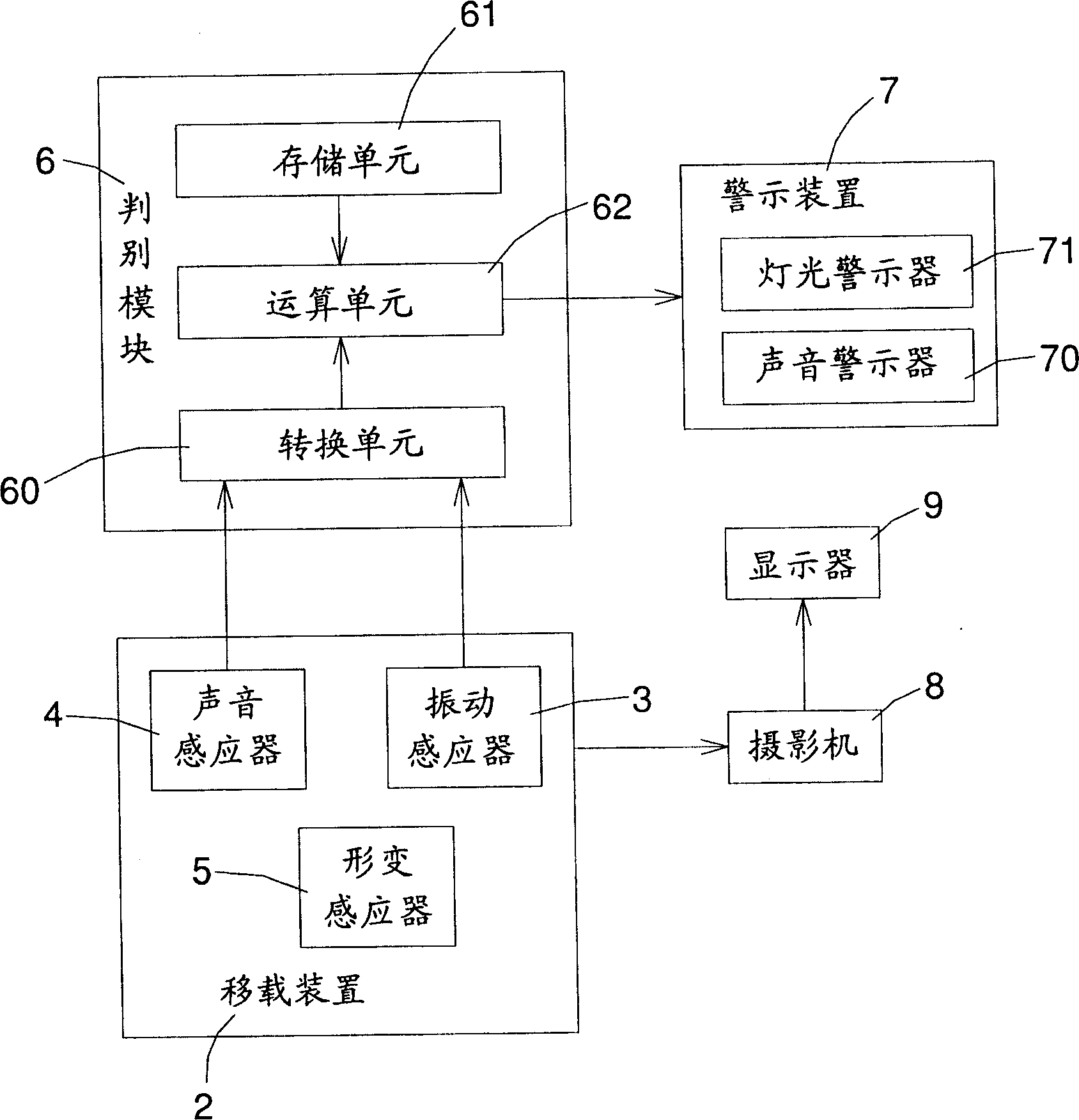

[0028] Please see figure 2 As shown, it is the first preferred embodiment of the safety monitoring mechanism of the wafer process platform of the present invention, including:

[0029] A vibration sensor 3 is arranged on the transfer device 2 of the wafer process platform for detecting the vibration generated when the transfer device 2 is in operation;

[0030] A sound sensor 4 is arranged on the transfer device 2 of the wafer process platform for detecting the sound generated when the transfer device 2 is in operation;

[0031] A deformation sensor 5 is arranged on the transfer device 2 of the wafer process platform for detecting the curvature or displacement generated when the transfer device 2 is in operation;

[0032] A discrimination module 6 includes a conversion unit 60, a storage unit 61 and a computing unit 62, the conversion unit 60 can be used to receive the vibration or vibration detected by the vibration sensor 3 or the sound sensor 4 or the deformation sensor 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com