Magnetic suspension bearing differential transformer type displacement sensor

A differential transformer type, displacement sensor technology, applied in the field of displacement sensors, can solve the problems of increased system cost, troublesome assembly process, loose sensor, etc., and achieves the effects of reliable performance, simple circuit and large inductance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

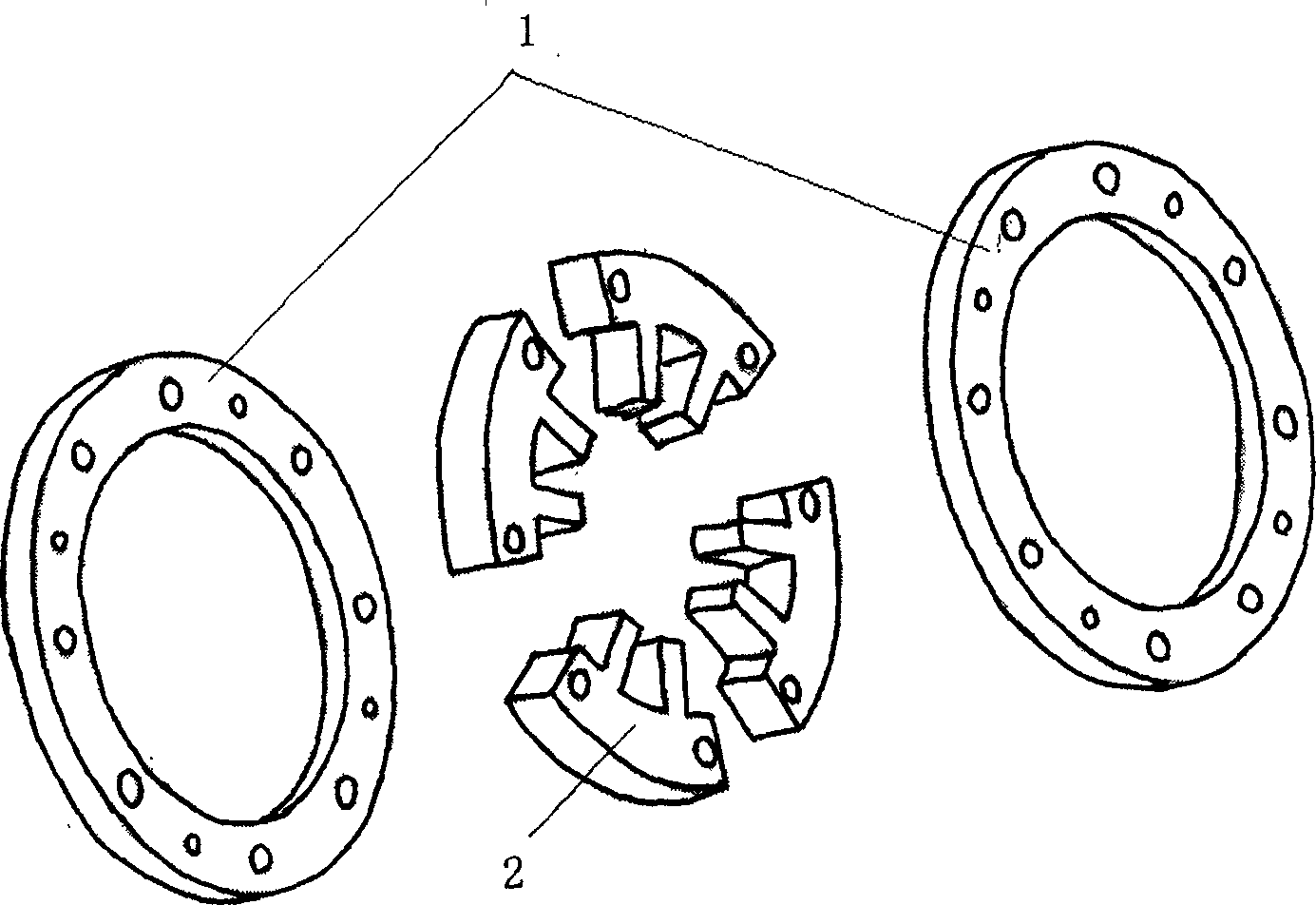

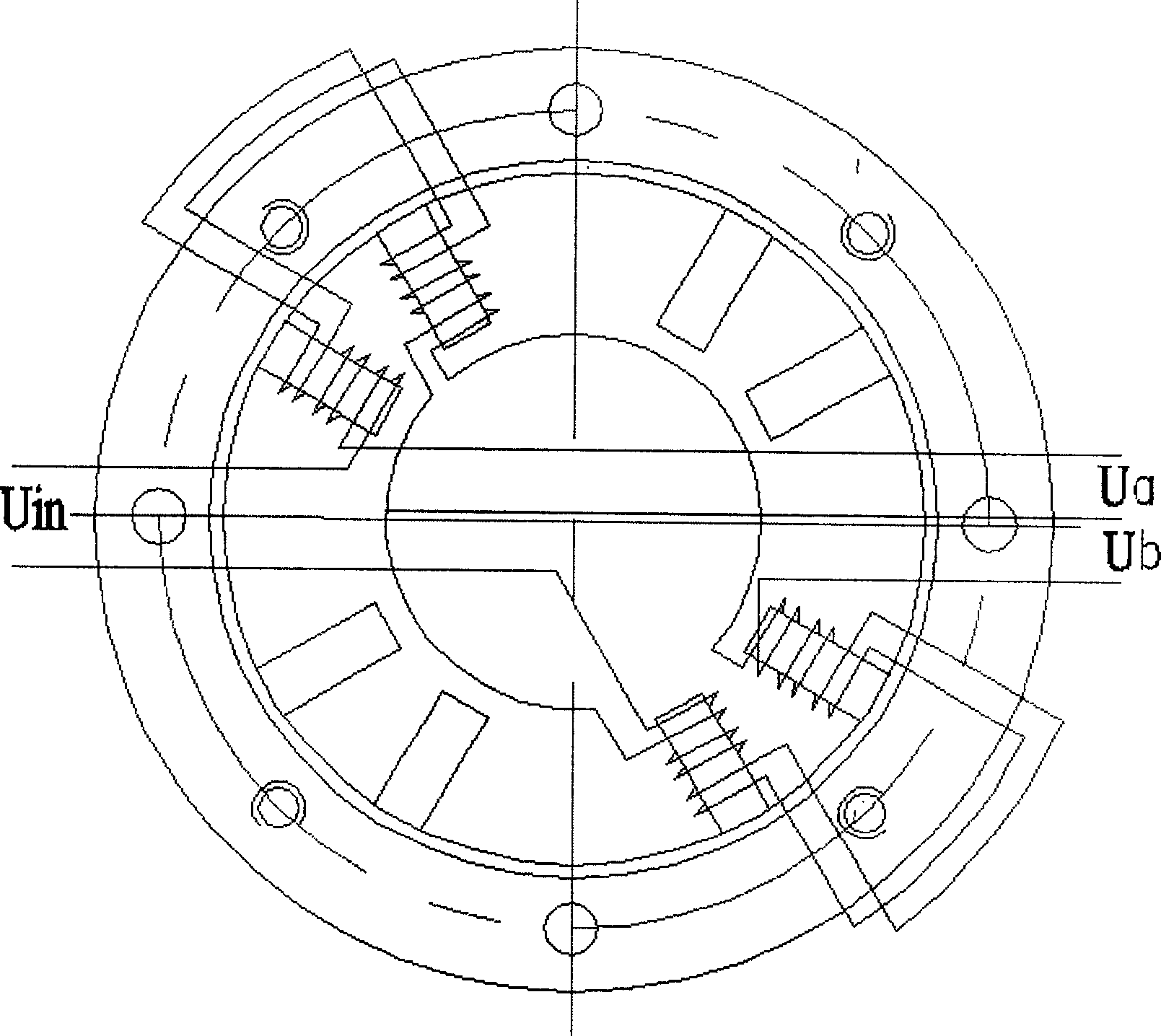

[0017] like figure 1 As shown, the mechanical structure of the differential transformer of the present invention consists of a splint 1 and a magnetic core 2 . The magnetic core 2 is formed by stacking iron-nickel alloy 1J79 circular laminations with a thickness of 0.05mm. A certain number of 1J79 laminations are laminated to a certain thickness and pressed tightly; The two ends of the core, and fix the two splints and the magnetic core with rivets; then perform wire cutting, cut out the outer circle and magnetic poles; figure 1 The shape of the middle magnetic core; finally grind the outer circle and the inner circle of the pole. Use polytetrafluoroethylene or plastic to process the coil frame of the transformer, and use QZ type high-strength enameled wire with a wire diameter of 0.23mm to wind in parallel for 50 turns. After the coil is wound, before assembly, it is necessary to ensure that each coil is available, that is, to ensure that each coil is conductive (not discon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com