Full-fiedl correction method for laser scanning cofocal microscope scanning distortion phenomenon

A confocal microscope and laser scanning technology, applied in the field of full-field correction, can solve the problems of complexity, inability to correct, reduce scanning speed, etc., and achieve the effect of simple operation and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

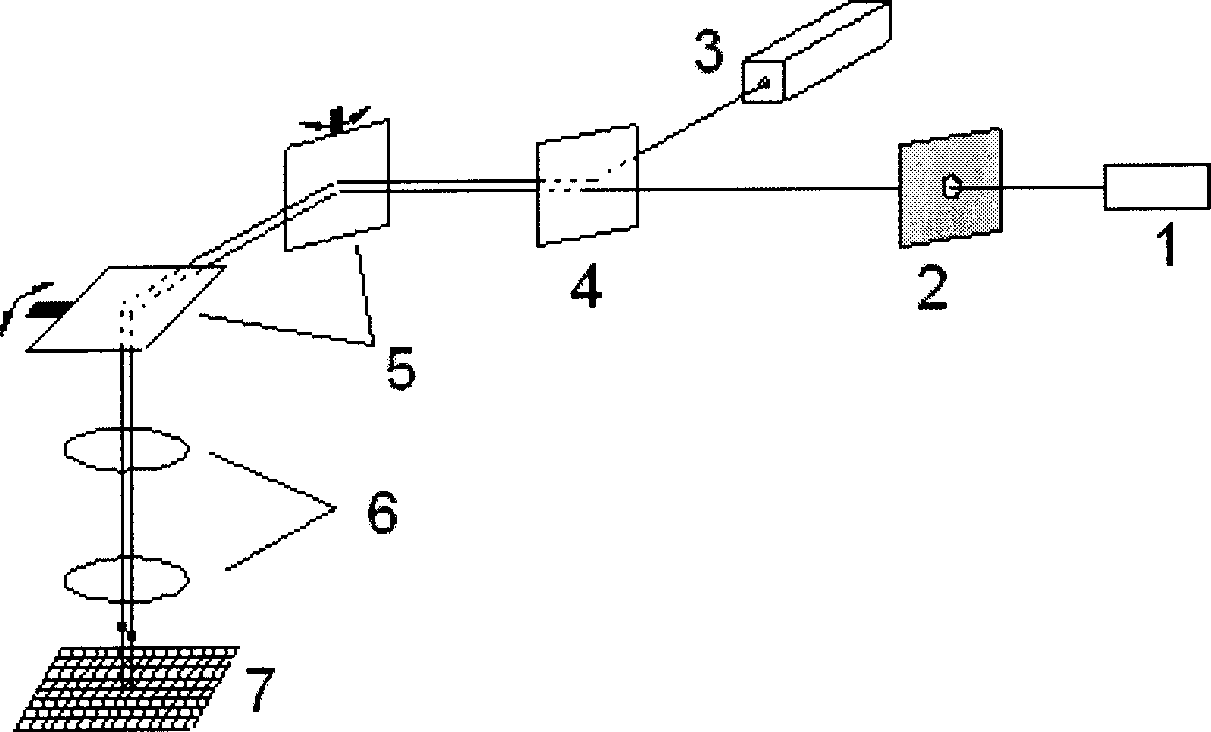

[0024] The principle and specific implementation method of the present invention will be further described below in conjunction with the accompanying drawings.

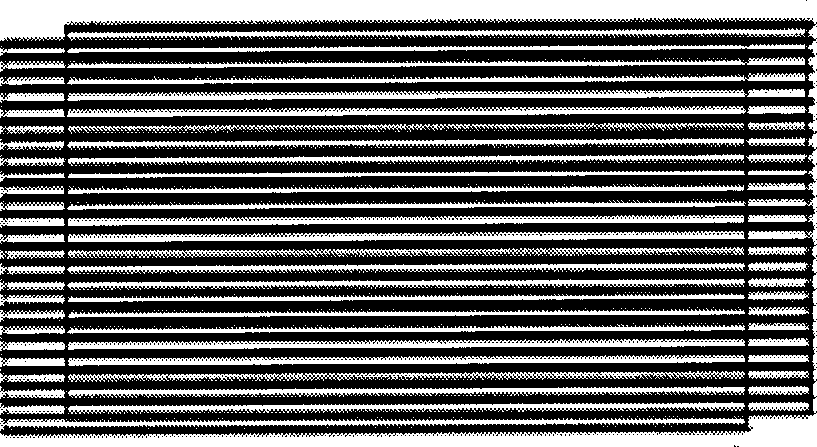

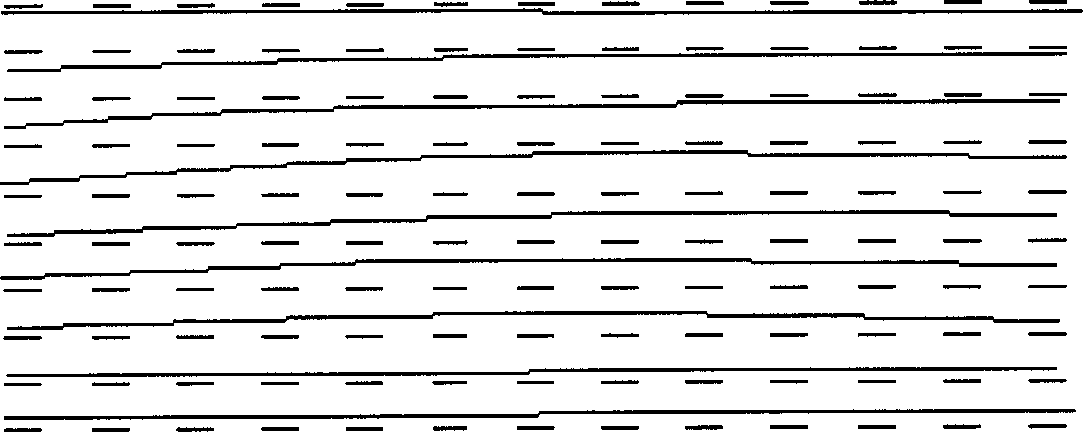

[0025] In order to achieve the above-mentioned purpose of the invention. The present invention needs to adopt a one-dimensional standard grating specimen, use the LSCM scanning moiré method to obtain the scanning moiré, and then obtain the displacement field information of the whole field area through the moiré phase shift method, and extract the distortion information of the scanning control unit, thereby achieve the purpose of calibration. The scanning moiré method is a geometric moiré method realized in a high-power microscope based on the principle of the traditional moiré method. The main principle is to form a specimen grating on the surface of the sample by etching or transferring the grating. The lines are scanned line by line according to certain rules, so a reference grid will be formed on the surface of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com