Process for preparing polystyrene/Fe3O4 composite magnetic micro ball

A technology of polystyrene microspheres and composite magnetism, which is applied in the field of preparation of composite magnetic microspheres and can solve problems such as pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

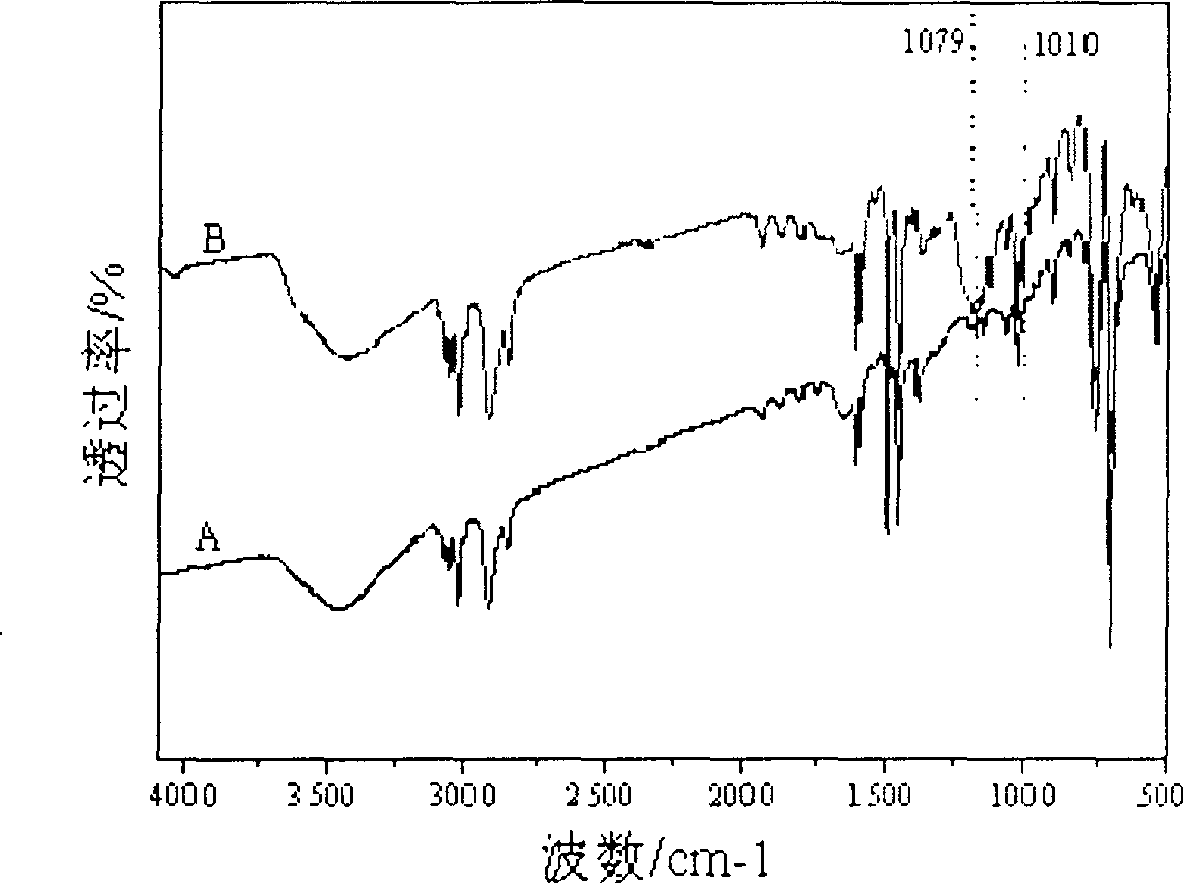

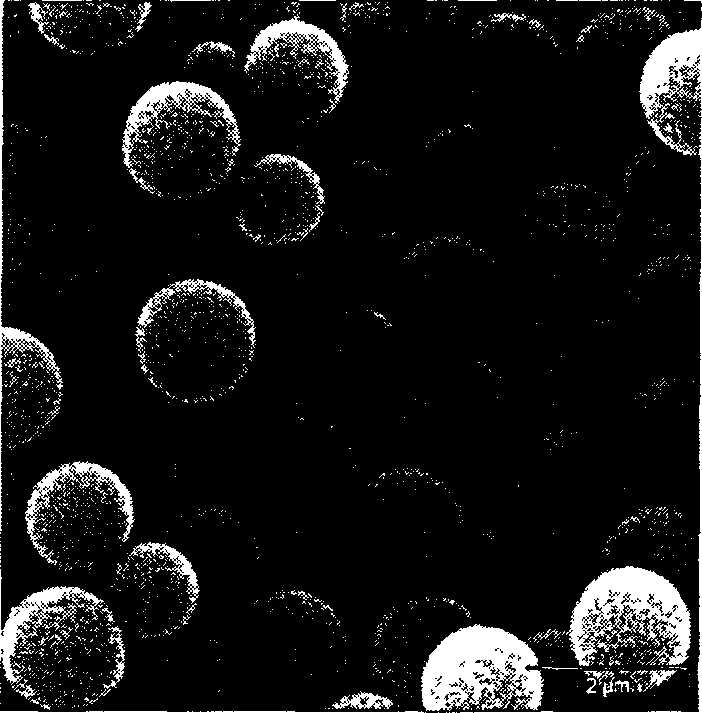

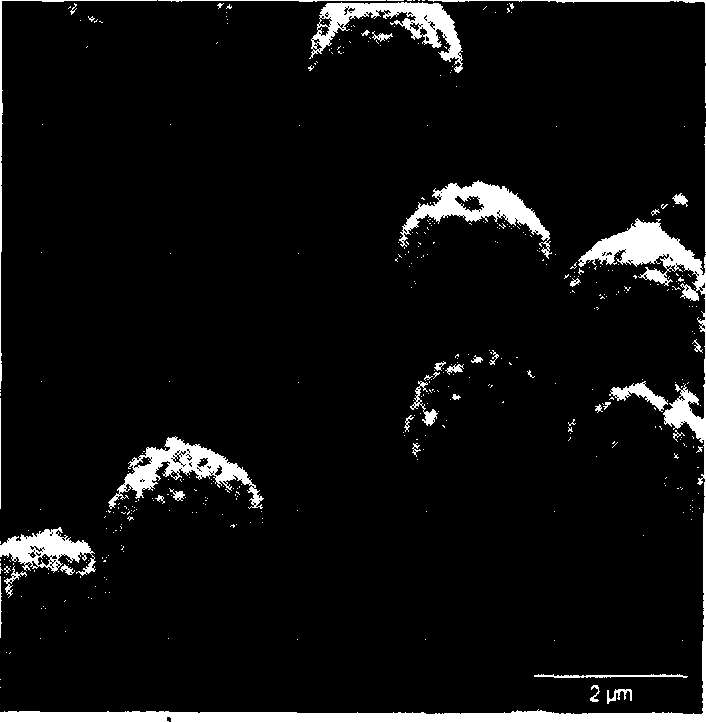

Method used

Image

Examples

Embodiment 1

[0018] Example 1: Mix 2g polystyrene microspheres with 20g concentration of 98% sulfuric acid, stir magnetically and condense to reflux, the reaction temperature is 40°C, and the reaction time is 8h. After the reaction, the solid matter is centrifuged, and the concentration is respectively Wash with 2% NaOH dilute solution and distilled water to obtain sulfonated polystyrene microspheres with negative charge on the surface;

[0019] Disperse 1 g of the sulfonated polystyrene microspheres with a negative charge on the surface in 8 g of polydiallyldimethylammonium chloride aqueous solution with a concentration of 1 mg / (ml 0.5 M NaCl), let it stand for adsorption for 20 minutes, and then wash with centrifugal water ;

[0020] Then disperse in 8g of sodium polystyrene sulfonate aqueous solution with a concentration of 0.5mg / (ml 0.5M NaCl), let it stand for 20min for adsorption, and then centrifuge and wash with water;

[0021] Then disperse in 8g of polydiallyldimethylammonium ch...

Embodiment 2

[0023] Embodiment 2: Mix 1g polystyrene microspheres with 12g concentration of sulfuric acid that is 98%, magnetic stirring and condensing reflux, reaction temperature 50 DEG C, reaction time 10h, centrifuge and separate solid matter after reaction, use concentration respectively Wash with 2% NaOH dilute solution and distilled water to obtain sulfonated polystyrene microspheres with negative charge on the surface;

[0024] Disperse 1 g of the above-mentioned sulfonated polystyrene microspheres with negative charge on the surface in 10 g of polydiallyldimethylammonium chloride aqueous solution with a concentration of 1 mg / (ml 0.5M NaCl), let it stand for adsorption for 30 minutes, and then wash it with centrifuge and water ;

[0025] Disperse in 10 g of sodium polystyrene sulfonate aqueous solution with a concentration of 0.5 mg / (ml 0.5 M NaCl), let stand for adsorption for 30 min, and then centrifuge and wash with water;

[0026] Then disperse in 10g of polydiallyldimethylamm...

Embodiment 3

[0030] Embodiment 3: 2g polystyrene microspheres and 26g concentration are the sulfuric acid that is 98% to mix uniformly, magnetic stirring and condensing reflux, reaction temperature 50 ℃, reaction time 11h, centrifuge and separate solid matter after reaction, respectively with the concentration of Wash with 2% NaOH dilute solution and distilled water to obtain sulfonated polystyrene microspheres with negative charge on the surface;

[0031] Disperse 1 g of the above-mentioned sulfonated polystyrene microspheres with negative charge on the surface in 11 g of polydiallyldimethyl ammonium chloride aqueous solution with a concentration of 1 mg / (ml 0.5M NaCl), let stand for adsorption for 30 min, and then wash with centrifugal water ;

[0032] Disperse again in 11 g of sodium polystyrene sulfonate aqueous solution with a concentration of 0.5 mg / (ml 0.5 M NaCl), let stand for adsorption for 40 min, and then centrifuge and wash with water;

[0033] Then disperse in 10g of polydia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com