A method for purifying flue gas by use of powdered activated coke

A technology for activated coke and flue gas, applied in the field of flue gas purification, can solve the problems of high mechanical loss of activated coke, high desulfurization cost, low denitration efficiency, etc., and achieve the effect of reducing purification cost, reducing diffusion resistance and reducing engineering investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

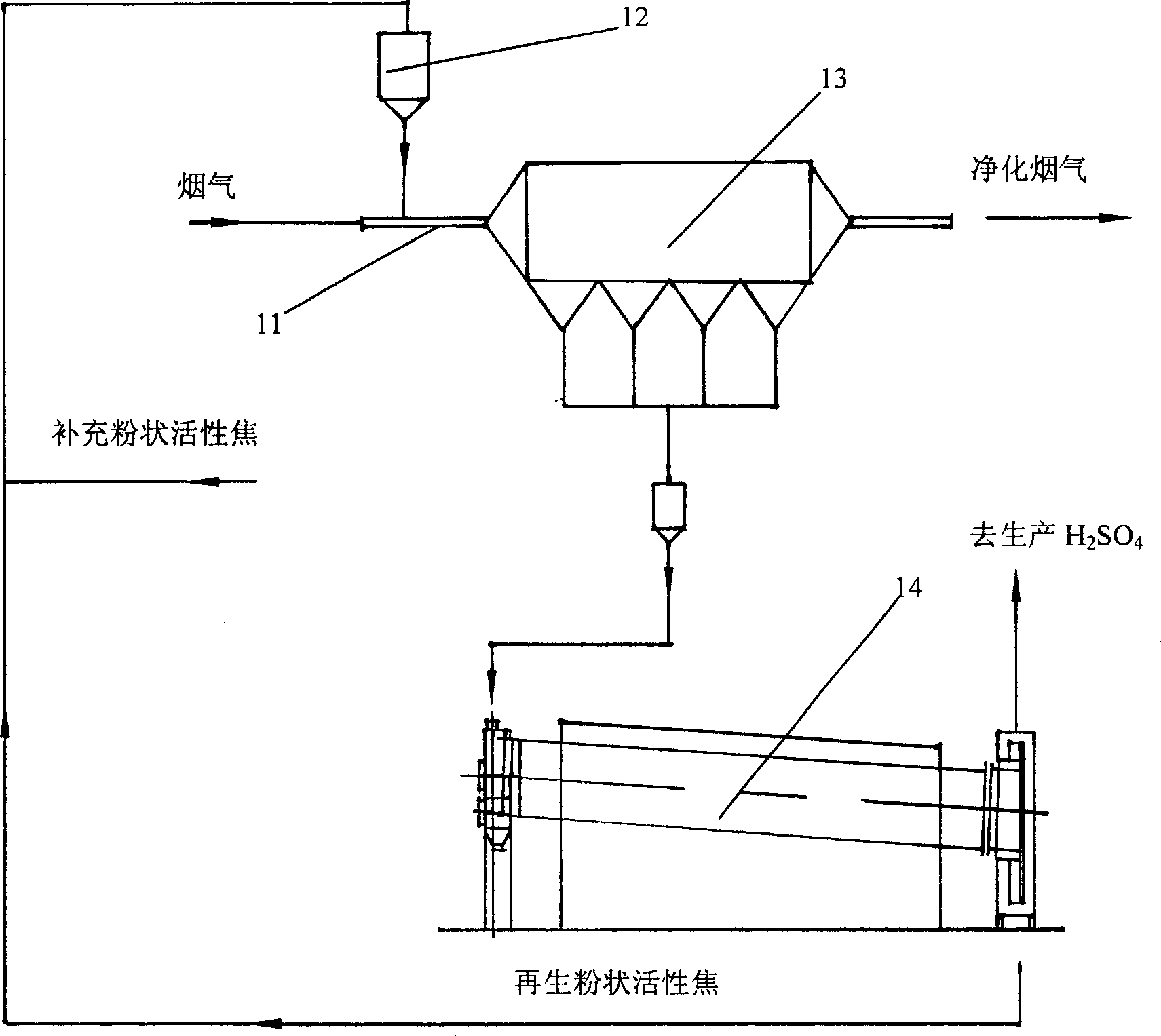

[0012] Embodiment 1, flue gas purification desulfurization, denitrification, demercury

[0013] use figure 1 The flue gas pipeline injection purification process shown, the SO in the flue gas 2 The concentration is 1000mg / m 3 , NO X The concentration is 500mg / m 3 , Hg content is 20μg / m 3 , the temperature is 120°C, and the concentration of sprayed active coke is 1000mg / m 3 , powdered active coke particles 500-600μm, iodine value 400mg / g, water content 6%. The whole process SO 2 The removal rate is 90%, NO X The removal rate is 30%, the Hg removal efficiency is 95%, the active coke powder is recycled after regeneration, and the high concentration of SO obtained after regeneration 2 The gas is used to produce sulfuric acid. If powdered activated coke is sprayed into the flue gas, 100-500mg / m 3 NH 3 or CO, NO X The removal rate was 40%.

Embodiment 2

[0014] Embodiment 2, flue gas purification desulfurization, denitrification, demercury

[0015] flue gas SO 2 The content is 3000mg / m 3 , NO X The concentration is 300mg / m 3 , Hg content is 10μg / m 3 , the temperature of the flue gas is 120°C, the flue gas is passed into the flue gas pipeline, and 3800mg active coke powder / m 3 The injection amount of flue gas injects active coke into the pipeline, the powdered active coke particles are 200-400μm, the iodine value is 600mg / g, the water content is 8%, and the added NH 3 The concentration of reducing agent mixed with CO is 600mg / m 3 (NH 3 / CO is 1), the Hg removal rate of the whole process flue gas is 93%, SO 2 The removal rate is 92%, NO X The removal rate was 49%. Activated coke powder is recycled after regeneration, and the high concentration of SO obtained after regeneration 2 The gas is used to produce sulfuric acid.

Embodiment 3

[0016] Embodiment 3, flue gas purification desulfurization, denitrification, demercury

[0017] flue gas SO 2 The content is 7500mg / m 3 , NO X The concentration is 600mg / m 3 , Hg content is 25μg / m 3 , the flue gas temperature is 180°C, the added NH 3 The concentration of reducing agent mixed with CO is 600mg / m 3 (NH 3 / CO is 0.5), the injection volume of active coke pipeline is 5000mg / m 3 , powdered active coke particles 10-80μm, iodine value 800mg / g, water content 15%. The whole process SO 2 The removal rate is 90%, NO X The removal rate is 45%, and the Hg removal rate is 95%. Activated coke powder is recycled after regeneration, and the high concentration of SO obtained after regeneration 2 The gas is used to produce sulfuric acid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Iodine value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com