Nano whisker modified resin dedicated to PP-R tube and its preparation method

A nano-whisker and PP-R technology, which is applied in the field of cold and hot water pipe materials for construction, can solve the problems of unsatisfactory mechanical properties, poor heat resistance, and difficulty in hot fluid transportation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Ordinary PP-R resin (melt flow rate is 0.30g / 10min) 96.5%

[0034] Modified Nano Calcium Carbonate Whiskers 2%

[0035] Rutile Nano Titanium Dioxide (d 50 =20nm) 1%

[0036] Polyacrylamide 0.5%

[0037] Wherein the modified nano-calcium carbonate whisker is modified by a silane coupling agent, the length of the nano-calcium carbonate whisker used is 0.5 μm, and the diameter is 10-50 nm.

[0038] The modified nano-whiskers, rutile nano-titanium dioxide, PP-R resin and dispersant are uniformly pre-mixed in a high-speed mixer; the solid mixture is fully blended and smelted in a molten state; the blended and smelted material is extruded with a screw , Granulation.

Embodiment 2

[0040] Ordinary PP-R resin (melt flow rate is 0.30g / 10min) 95%

[0041] Modified Nano Calcium Carbonate Whiskers 3%

[0042] Modified nano zinc oxide whisker 0.5%

[0043] Rutile Nano Titanium Dioxide (d 50 =20nm) 1%

[0044] Polyacrylamide 0.5%

[0045] Wherein the modified nano-calcium carbonate whisker is modified by a silane coupling agent, the length of the nano-calcium carbonate whisker used is 2 μm, and the diameter is 10-50 nm.

[0046] The modified nano-zinc oxide whiskers used are modified by KH560 coupling agent, and the nano-zinc oxide whiskers used are in the shape of three-dimensional four needles, the center body diameter of the whiskers is 300nm, and the length of the needles is 15 μm.

[0047] The modified nano-whiskers, PP-R resin and dispersant are uniformly pre-mixed in a high-speed mixer; the solid mixture is fully blended and smelted in a molten state; the blended and smelted material is extruded and granulated by a screw.

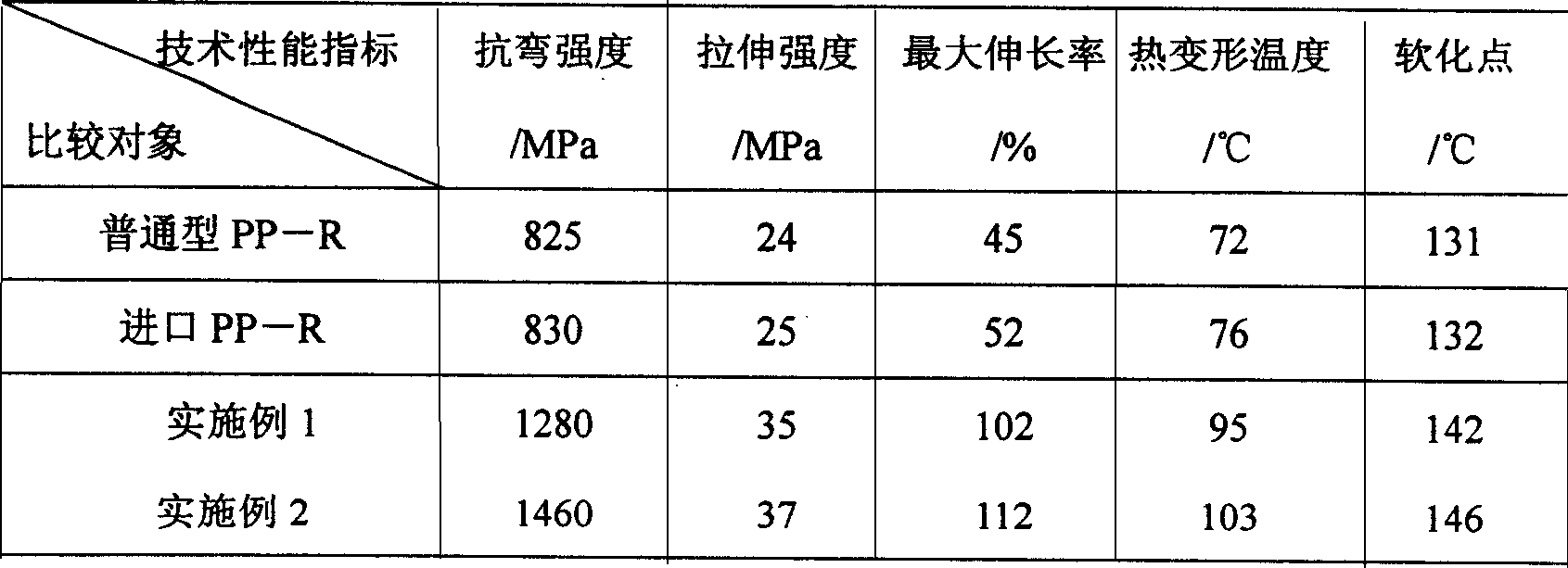

[0048] Schedule 1:

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt flow velocity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com