Dynamic pressure probe and method for measuring high temp jet dynamic pressure by the probe

A probe and pressure measurement technology, applied in the direction of measuring fluid pressure, measuring devices, instruments, etc., can solve the problems of not being able to quickly respond to the jet flow pressure signal, shortening the service life of the pitot tube, and accelerating the ablation of the head of the pitot tube, to achieve Reduce the residence time, reduce the cost of measurement, and the effect of real measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

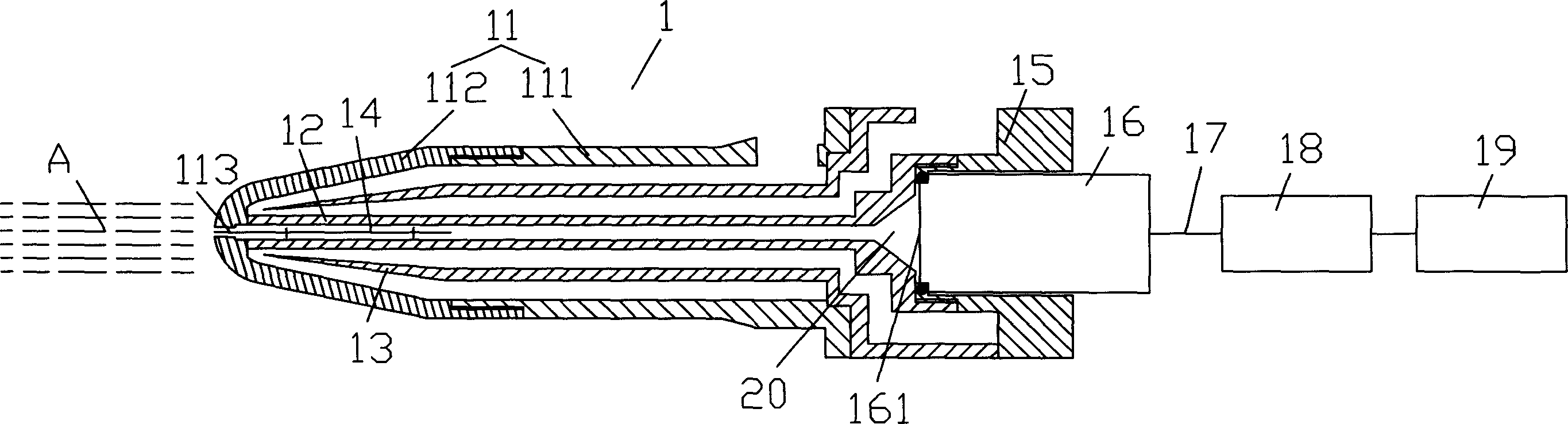

[0017] The dynamic pressure measuring probe required by the space-time high-response measurement method of high-temperature jet dynamic pressure of the present invention is as follows: figure 1 As shown, it includes a water-cooled conical pressure probe and a pressure sensor. The water-cooled conical pressure probe 1 includes an outer tube 11. The outer tube 11 includes a detachably connected outer tube body 111 and a conical head 112. The front end of the conical head 112 is open. There is a sampling hole 113, the center of the outer pipe 11 is connected to the water-air isolation pipe 12, an air flow channel 14 is formed at the center of the water-air isolation pipe 12, and an inlet and outlet water isolation pipe 13 is provided between the water-air isolation pipe 12 and the outer pipe 11. A cooling water inlet channel is formed between the water inlet and outlet isolation tube 13 and the water-air isolation tube 12, and a water inlet is provided on the water inlet channel, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com