Steel ball coal mill with dual inputs and dual outputs

A steel ball pulverizer, double-in and double-out technology, applied in grain processing and other directions, can solve the problems of large concentration deviation of air-pulverized mixture, affecting boiler combustion thermal efficiency, poor pulverized coal uniformity, etc., to achieve stable output and fineness, and structure. Simple, low air-to-coal ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

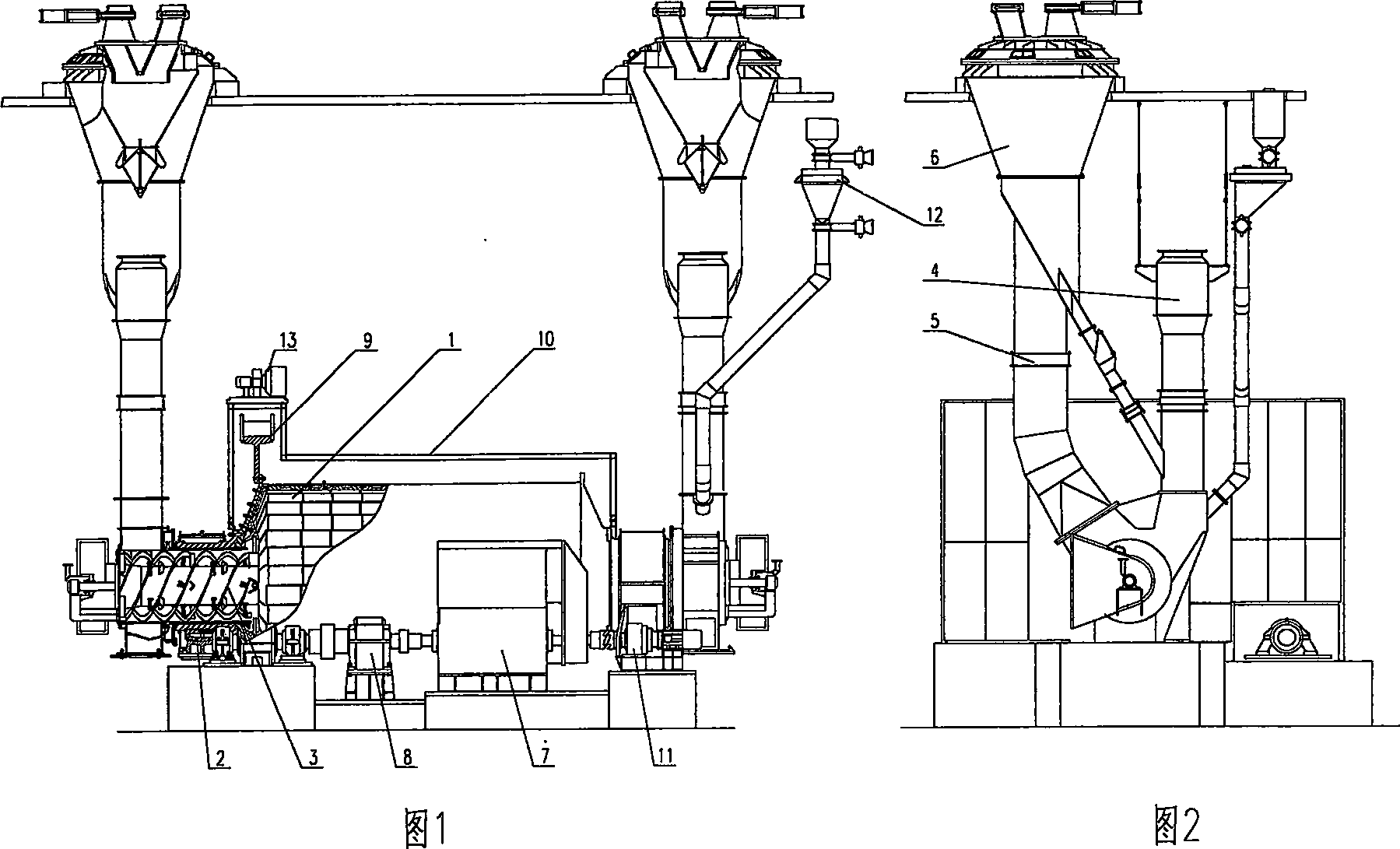

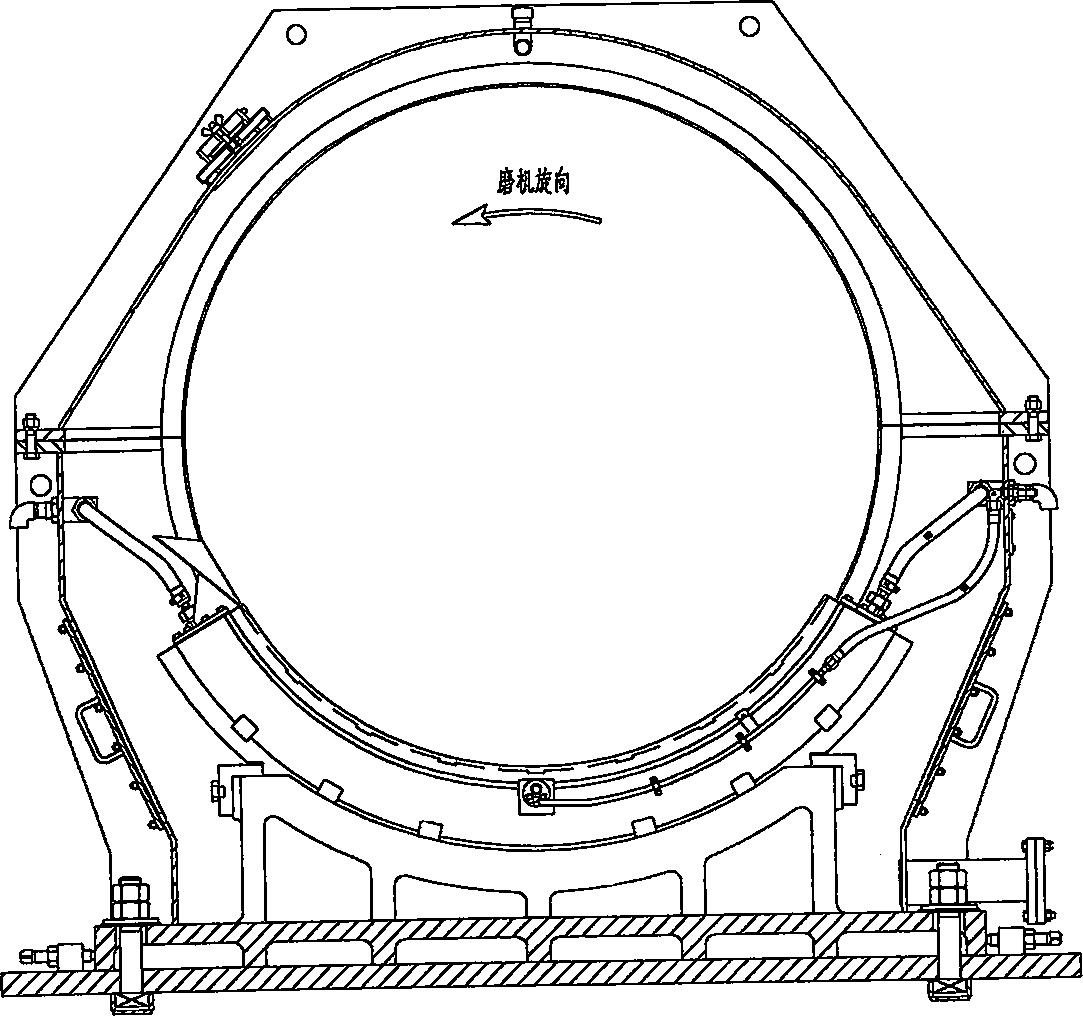

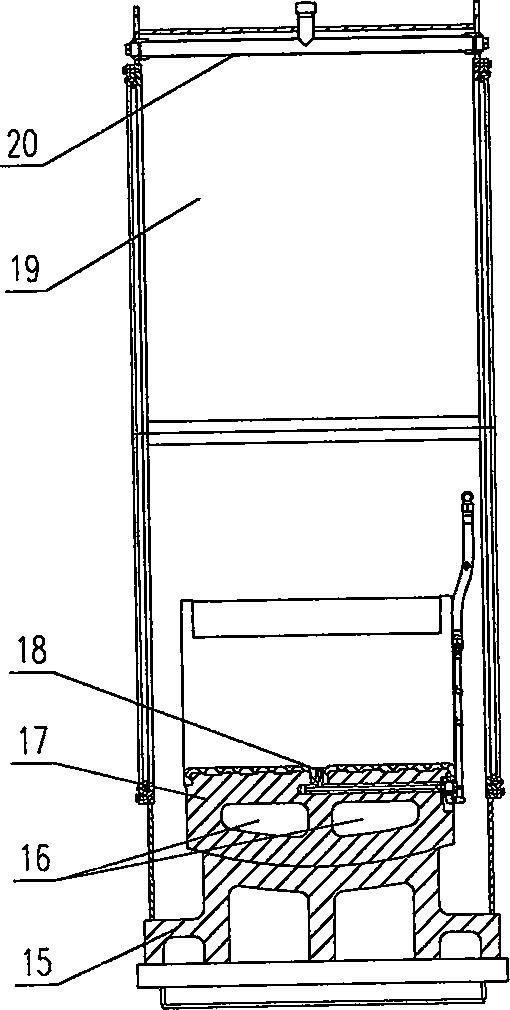

[0019] As shown in Figures 1 and 2, the double-inlet and double-outlet steel ball coal mill of the present invention includes a rotating part 1, a main bearing 2, a left and right screw conveyor 3, a coal mixing box 4, a separator connecting pipe 5, a separator 6, and a main motor 7 , reducer 8, large and small gear transmission device 9, soundproof cover 10, slow speed transmission device 11, ball adding device 12, large gear sealing device 13.

[0020] The rotating part 1 is supported by the main bearing 2 and arranged on the foundation, and the screw conveyors 3 are arranged symmetrically at the left and right ends of the rotating part 1 . The coal mixing box 4 is connected with the bottom of the screw conveyor 3 through the coal drop pipe. The separator 6 is connected to the annular channel in the screw conveyor 3 through the separator connecting pipe 5 . The cylinder of the rotating part 1 is driven to rotate by the main motor 7 through the reducer 8 and the large and sm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com