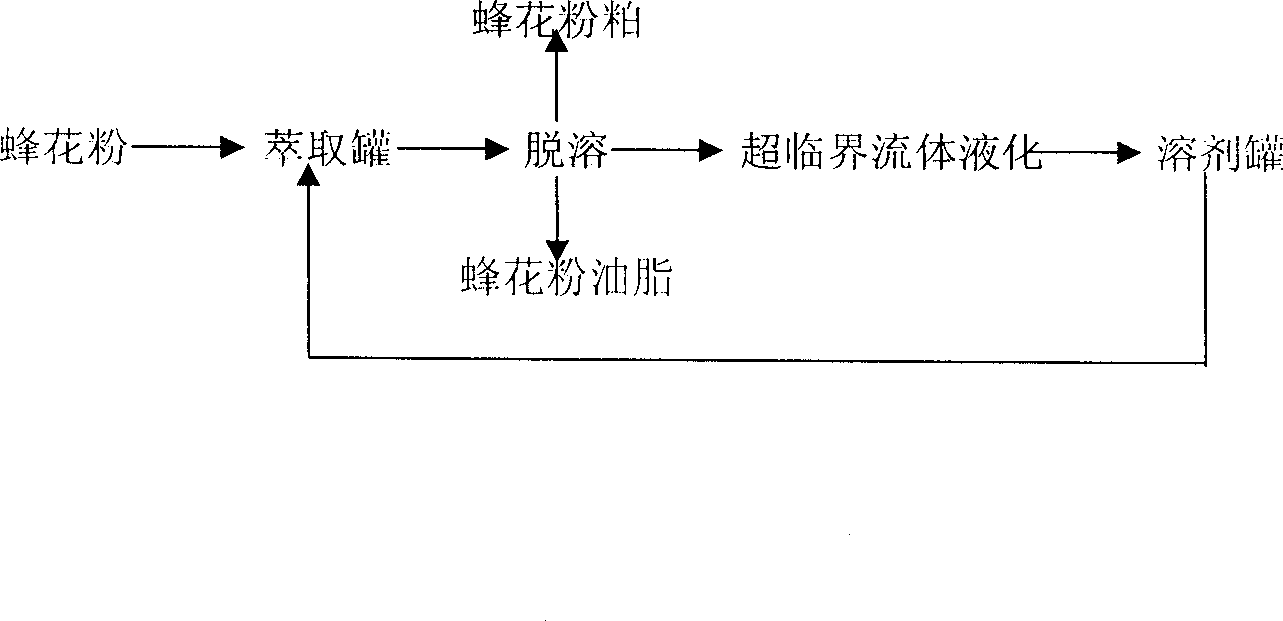

Method for extracting oil and fat of bee pollen through supercutical fluid

A technology of supercritical fluid and bee pollen, which is applied in the direction of fat oil/fat production and fat generation, can solve the problems of high investment cost and difficulty in industrialization, achieve low operating temperature, easy control of operating parameters, and save a lot of organic solvents Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Take 2 kg of rapeseed pollen (moisture content 5%) as raw material, add it into a 15L extraction tank, then feed liquefied petroleum gas into the extractor, and extract for 1 hour under the conditions of extraction temperature 20°C and extraction pressure 0.1Mpa Desolventization of bee pollen meal and mixed oil is carried out, and the solvent is compressed and recycled to obtain bee pollen meal and bee pollen oil, and the oil yield is 4.0% for the first time. Desolvation conditions of bee pollen meal: the degree of vacuum is 0.07Mpa, the temperature is 40°C, and the time is 0.5 hours. Mixed oil precipitation conditions: vacuum degree 0.08Mpa, temperature 40°C, time 0.5 hour.

[0029] Carry out the second extraction according to the first extraction conditions, the oil yield is 0.5%

[0030] The third extraction was carried out according to the first extraction conditions, and the oil yield was 0.3%.

Embodiment 2

[0032] Take 2 kg of rapeseed pollen (moisture content 5%) as raw material, put it into a 15L extraction tank, then feed liquefied petroleum gas into the extractor, and extract for 1 hour under the conditions of extraction temperature 40°C and extraction pressure 0.2Mpa Desolventization of bee pollen meal and mixed oil is carried out, the solvent is compressed and recycled to obtain bee pollen meal and bee pollen oil, and the first oil yield is 4.5%. Desolvation conditions of bee pollen meal: the degree of vacuum is 0.07Mpa, the temperature is 40°C, and the time is 0.5 hours. Mixed oil precipitation conditions: vacuum degree 0.08Mpa, temperature 40°C, time 0.5 hour.

[0033] The second extraction was carried out according to the first extraction conditions, and the oil yield was 0.4%.

[0034] The third extraction was carried out according to the first extraction conditions, and the oil yield was 0.1%.

Embodiment 3

[0036] Take 2 kg of rapeseed pollen (moisture content 5%) as raw material, put it into a 15L extraction tank, then feed liquefied petroleum gas into the extractor, and extract for 1 hour under the conditions of extraction temperature 50°C and extraction pressure 0.4Mpa Desolventization of bee pollen meal and mixed oil is carried out, and the solvent is compressed and recycled to obtain bee pollen meal and bee pollen oil, and the oil yield is 4.7% for the first time. Desolvation conditions of bee pollen meal: the degree of vacuum is 0.07Mpa, the temperature is 40°C, and the time is 0.5 hours. Mixed oil precipitation conditions: vacuum degree 0.08Mpa, temperature 40°C, time 0.5 hour.

[0037] The second extraction was carried out according to the first extraction conditions, and the oil yield was 0.3%.

[0038] The third extraction was carried out according to the first extraction conditions, and the oil yield was 0.1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com