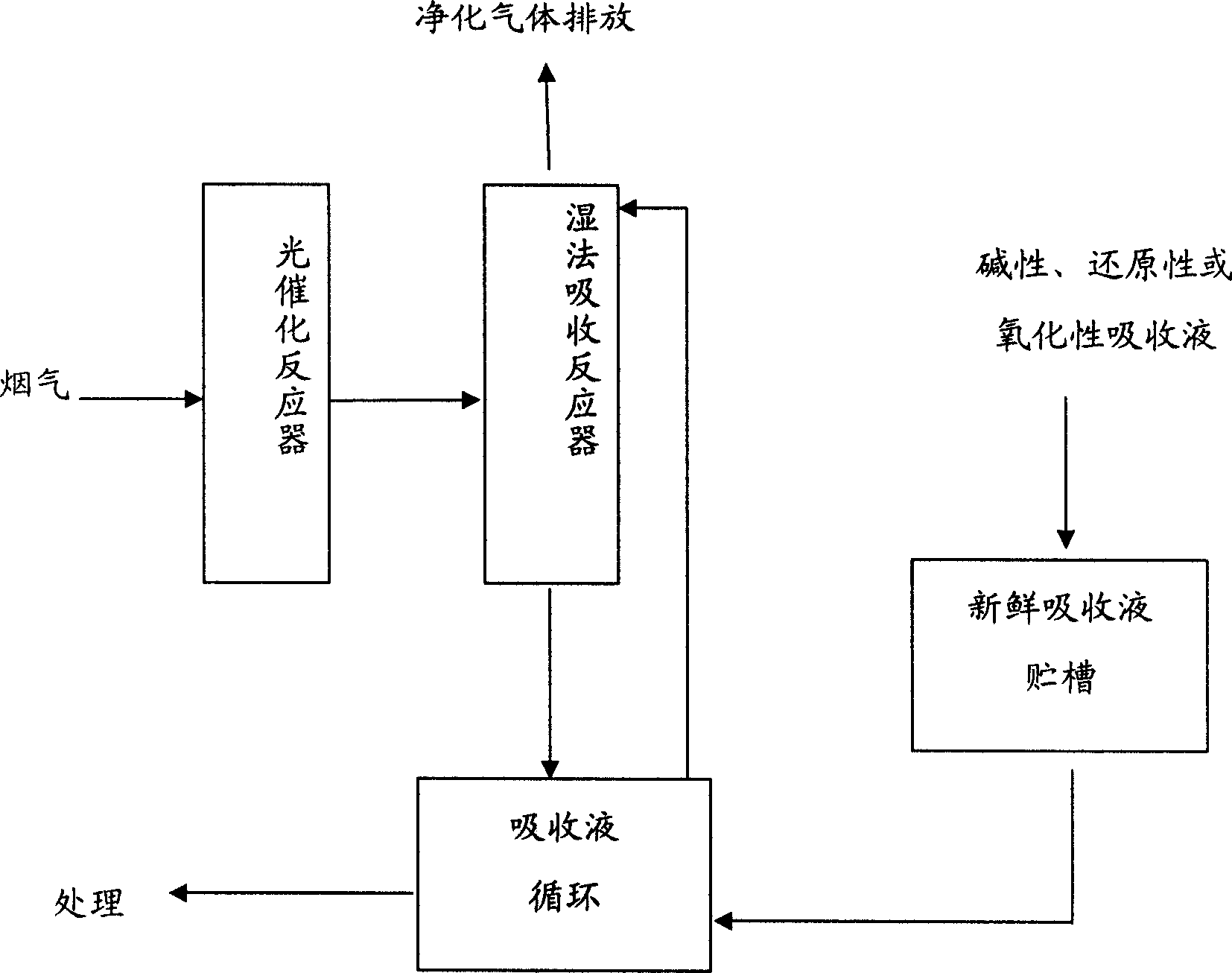

Photo-catalytic oxidation and wet method absorption combined wet method flue-gas denitration process

A photocatalytic oxidation and photocatalyst technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problem of low treatment efficiency of high-concentration nitrogen oxides, and achieve small footprint, simple equipment, and denitrification efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Formulated with 5% TiO 2 The suspension of the catalyst, using the coating method to immerse the glass fiber in the catalyst suspension and coat it for 3 to 5 times, after the coating is completed, the catalyst is dried at 80°C, and the catalyst loading is 0.7mg / cm 2 The loaded catalyst is folded and placed in the catalytic reactor, the ultraviolet light source is arranged in the catalytic reaction chamber, and the placement method is arranged symmetrically along the wall axis; NaOH solution is used as the denitrification absorption liquid, and the NaOH weight percentage in the solution is 5% . The flue gas to be treated enters the photocatalytic reactor for photocatalytic oxidation reaction. After testing, NO in the flue gas nitrogen oxide 2 The content of nitrogen oxides is increased from about 10% to more than 45%; the oxidized flue gas enters the absorption reactor and fully contacts with the absorption liquid. The test results of the discharged flue gas show that th...

Embodiment 2

[0025] Formulated with 5% TiO 2 The suspension of the catalyst, using the coating method to immerse the glass fiber into the catalyst suspension and coat it for 3 to 5 times, after the coating is completed, the catalyst is dried at 80°C, and the catalyst loading is 1.2mg / cm 2 The loaded catalyst is folded and placed in the catalytic reactor, the ultraviolet light source is arranged in the catalytic reaction chamber, and the placement method is arranged symmetrically along the wall axis; NaOH solution is used as the denitration absorption liquid, and the NaOH weight percentage in the solution is 10% . The flue gas to be treated enters the photocatalytic reactor for photocatalytic oxidation reaction. After testing, NO in the flue gas nitrogen oxide 2 The content of nitrogen oxides is increased from about 10% to more than 55%; the oxidized flue gas enters the absorption reactor and fully contacts with the absorption liquid. The test results of the discharged flue gas show that t...

Embodiment 3

[0027] Formulated with 5% TiO 2 The suspension of the catalyst, using the coating method to immerse the glass fiber in the catalyst suspension and coat it for 3 to 5 times, after the coating is completed, the catalyst is dried at 80°C, and the catalyst loading is 1.5mg / cm 2 The loaded catalyst is folded and placed in the catalytic reactor, the ultraviolet light source is arranged in the catalytic reaction chamber, and the placement method is symmetrically arranged along the wall axis; NaOH solution is used as the denitrification absorption liquid, and the NaOH weight percentage in the solution is 20% . The flue gas to be treated enters the photocatalytic reactor for photocatalytic oxidation reaction. After testing, NO in the flue gas nitrogen oxide 2 The content of nitrogen oxides is increased from about 10% to more than 65%; the oxidized flue gas enters the absorption reactor and fully contacts with the absorption liquid. The test results of the discharged flue gas show that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com