Ultra-fine pearlite high-strength rail steel and its preparation method

A pearlitic, high-strength technology, used in manufacturing tools, heat treatment equipment, heat treatment process control, etc., can solve problems such as brittle strength cannot be improved, plasticity is reduced, plasticity is affected, and hot workability is affected.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Ultra-fine pearlitic high-strength track steel, the alloy composition weight percentage is: C: 1.0-1.8; Al: 0.1-6.0; Cr: 0.1-2.5; Mn: 0.2-0.8; Si: 0-1.5; Mo: 0-0.8 ; Nb: 0.0-0.1; V: 0.0-0.1; Ti: 0.0-0.1; Re: 0.0-0.05; the balance is Fe.

[0029] The performance of the above-mentioned ultra-fine pearlitic high-strength rail steel with this structure feature is characterized by two aspects. One is that the tensile strength above 1300MPa can be obtained without quenching and tempering treatment, the yield strength above 900MPa, and the yield strength above 10% elongation; second, high wear resistance can be obtained without surface quenching.

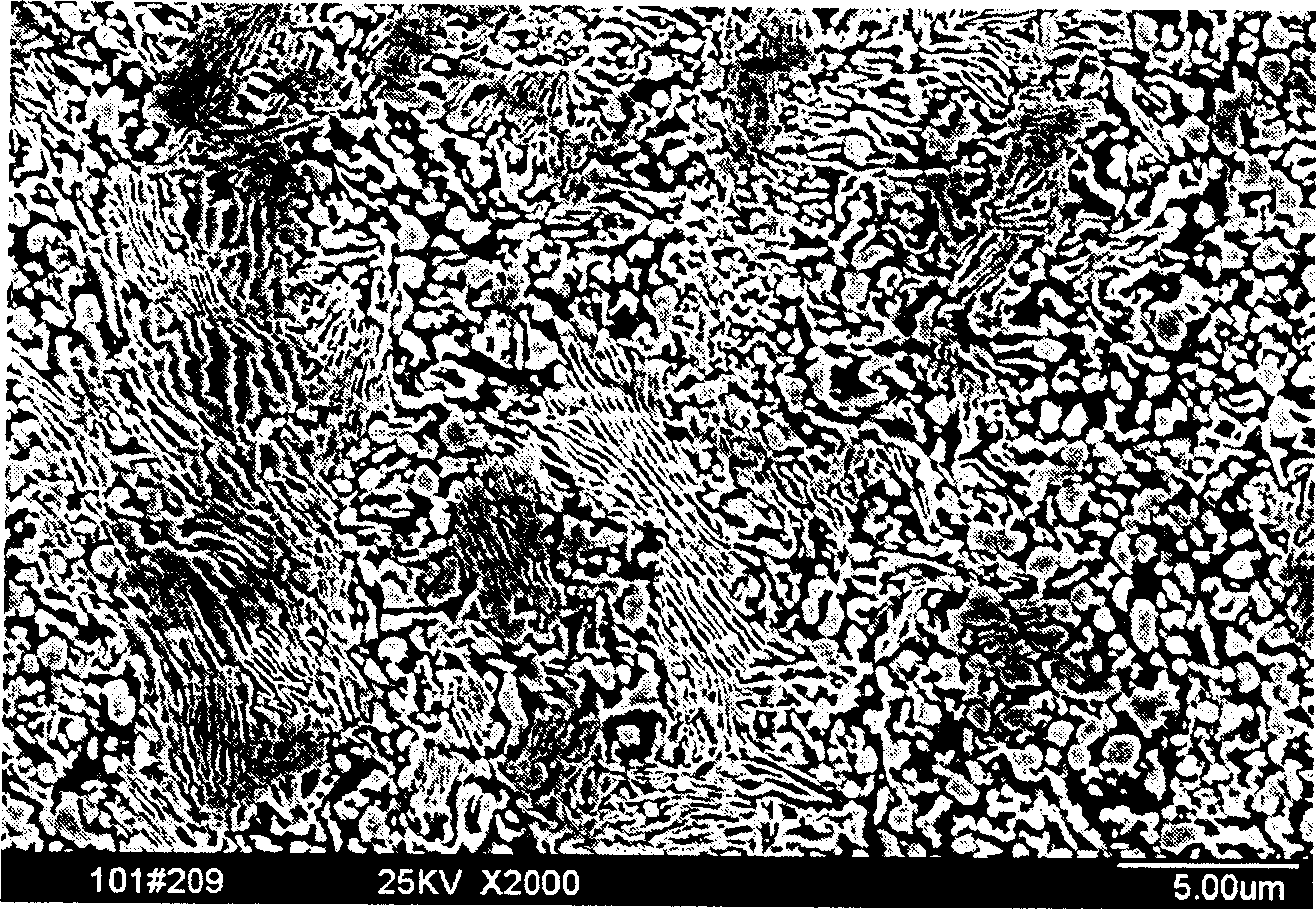

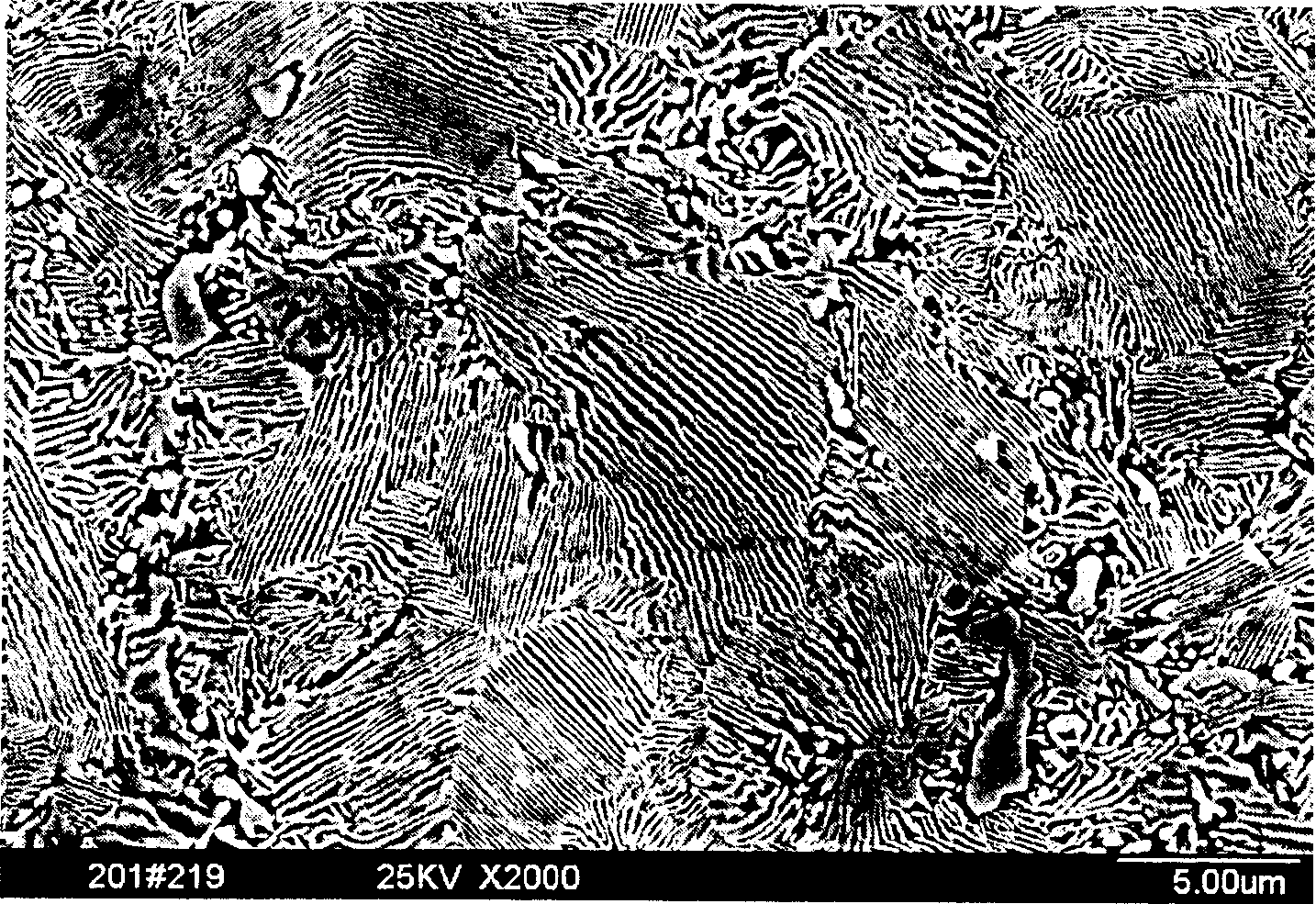

[0030] Make the proeutectoid carbides broken and spheroidized, the crystal grains are ultra-fine, and the structure is ultra-fine granular carbides distributed on the ultra-fine pearlite grains, the grain size is 2-6 μm, and the pearlite lamellar spacing is 0.1-0.2 μm , The size of granular carbides is 0.3-1 μm.

[0031] The above...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com