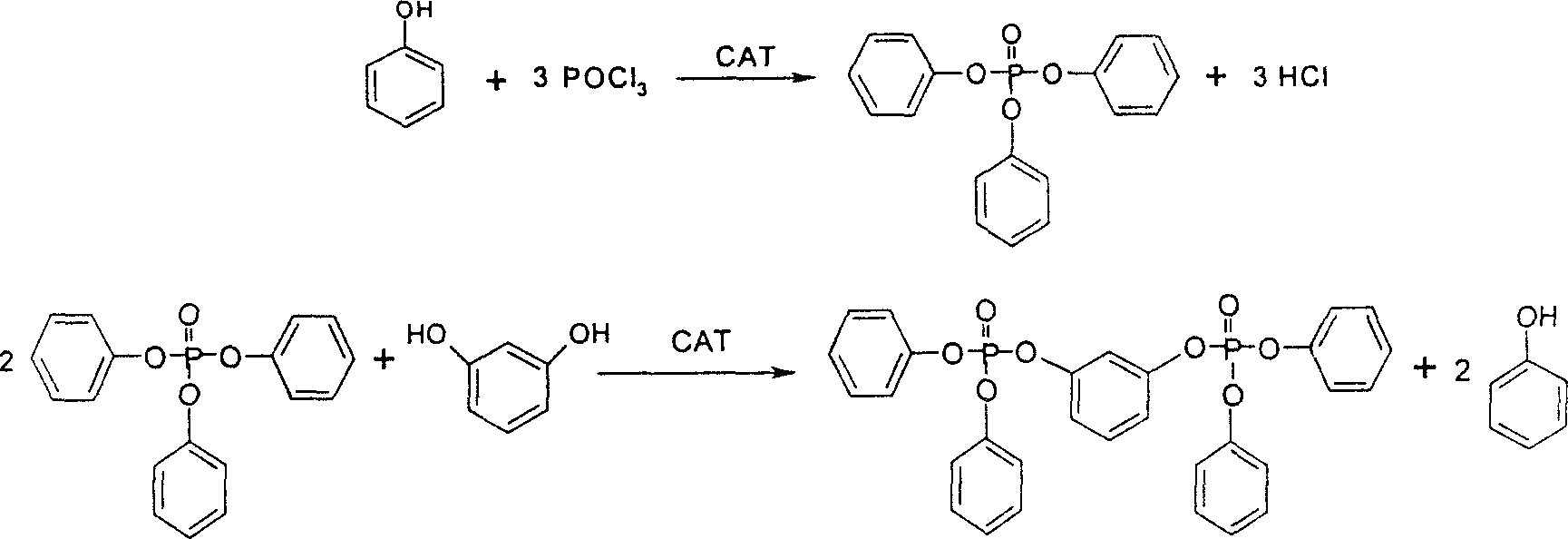

Prepn of fire retardant resorcinol tetraphenyldiphosphate

The technology of resorcinol tetraphenyl diphosphate and triphenyl phosphate is applied in the field of preparation of flame retardants, which can solve the problems of low product yield, seriousness, dark color of crude products, etc., and reduce pollution. , the effect of short reaction time and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1. add phenol 141.2g in the 250ml four-necked flask that reflux condenser (upper mouth is connected tail gas absorption device), electric stirrer and thermometer are equipped with, catalyzer aluminum trichloride 3.0g. Turn on the condensed water, stir, raise the temperature to 50°C and start adding POCl dropwise 3 76.65g, dropwise finished in 1-1.5 hours, the temperature gradually rose to 80°C during the dropwise addition. Then the temperature was raised to 100° C., kept for 1 hour, then raised to 140° C. for 1 hour, and the heating was stopped.

[0018] Add 27.5g of resorcinol, heat and stir, keep the vacuum below 10mmHg, react at 140-160°C for 60min, collect the phenol, then keep it at 180-220°C for about 90min, and the reaction is over. Stop heating, turn off the vacuum pump when the liquid temperature drops to 120°C, and suction filter while it is hot. The crude product is a yellow or brown transparent liquid, and the by-product phenol is reused. The ...

Embodiment 2

[0019] Embodiment 2. Add phenol 282.3g, catalyzer aluminum trichloride 3.0g in the 500ml four-necked flask that reflux condenser (upper mouth is connected tail gas absorption device), electric stirrer and thermometer are housed. Turn on the condensed water, stir, raise the temperature to 50°C and start adding POCl dropwise 3 153.3g, 1 to 1.5 hours to finish the drop, the temperature gradually rose to 80°C during the dropwise addition, then the temperature rose to 100°C, kept for 1 hour, then rose to 140°C for 1 hour, and stopped heating. Distill under reduced pressure to remove unreacted phenol, and collect components at 240-260° C. under a vacuum of 10 mmHg to obtain 293.0 g with a yield of 90.0%.

[0020] Take TPP68.7g (0.21mol), resorcinol 11.6g (0.105mol), join in the 150ml three-neck flask equipped with magnetic stirrer and thermometer, heat and stir, add 0.3g K 2 CO 3 , with a vacuum degree below 10mmHg, react at 120-130°C for 30 minutes, collect phenol, and then keep...

Embodiment 3

[0021] Embodiment 3. in the 500ml four-necked flask that is equipped with reflux condenser (upper mouth is connected with tail gas absorption device), electric stirrer and thermometer, add phenol 282.3g, catalyzer aluminum trichloride 3.0g. Turn on the condensed water, stir, raise the temperature to 50°C and start adding POCl dropwise 3 153.3g, 1 to 1.5 hours to finish the drop, the temperature gradually rose to 80°C during the dropwise addition, then the temperature rose to 100°C, kept for 1 hour, then rose to 140°C for 1 hour, and stopped heating. Distill under reduced pressure to remove unreacted phenol, and collect components at 240-260° C. under a vacuum of 10 mmHg to obtain 293.0 g with a yield of 90.0%.

[0022] Get TPP68.7g (0.21mol), resorcinol 11.6g (0.105mol), join in the 150ml three-neck flask that magnetic stirrer and thermometer are housed, heat and stir, heat and stir, add 0.2g sodium phenoxide, React at 10mmHg 130-140°C for 30 minutes, collect the phenol, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com