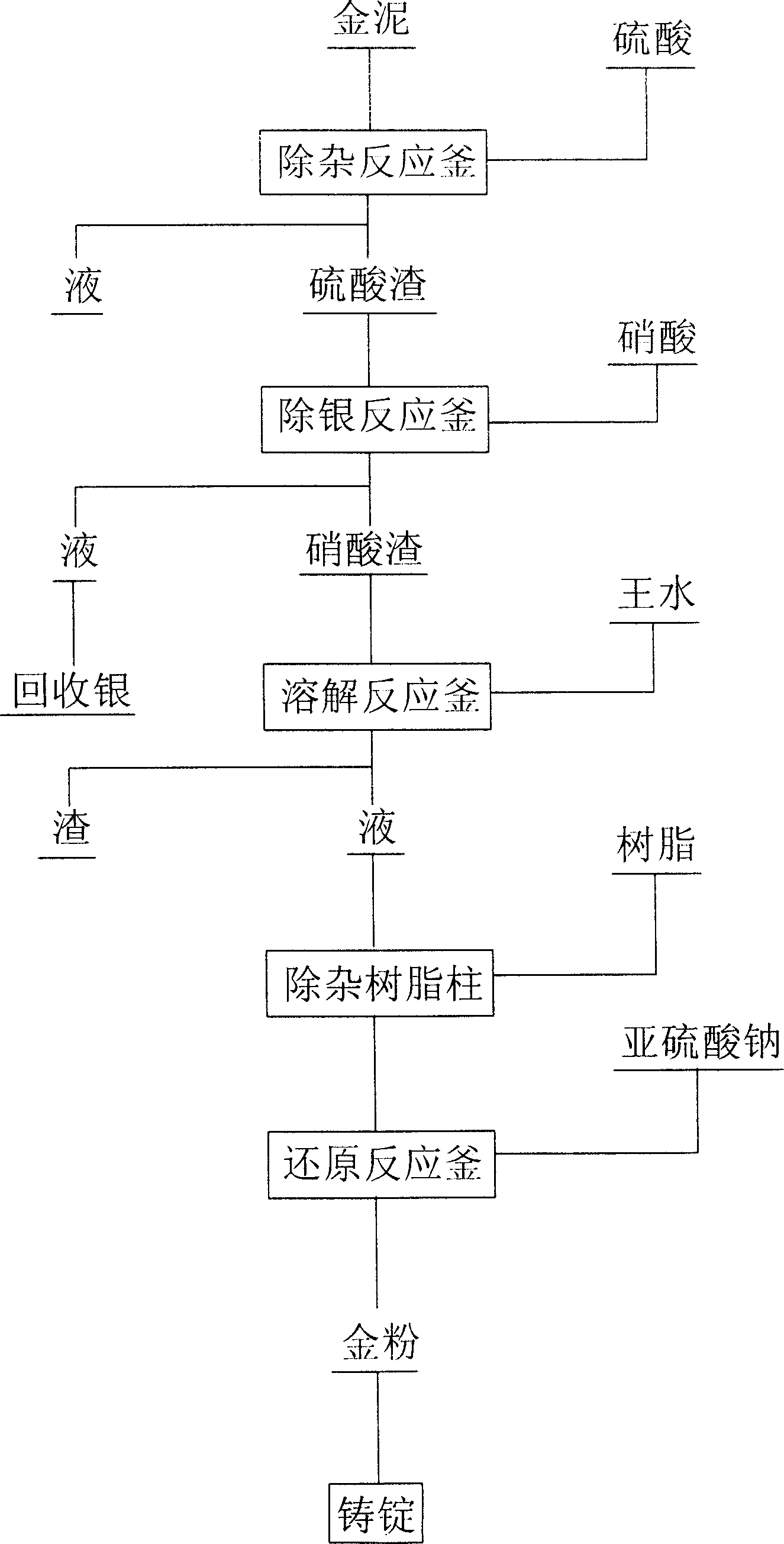

Gold purifying resin process

A technology of gold and craftsmanship, which is applied in the field of gold purification by resin method, can solve the problems of poor product quality, small application range, and complicated equipment, and achieve the effect of small footprint, good product quality, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0025] Carry out according to the following steps, take gold mud 285g, gold mud main composition: Au 18.97%, Ag 41.82%, Cu 0.023%, Pb 0.22%, Fe 0.31%;

[0026] step 1:

[0027] Dry and crush the gold mud of the above grade and add it to the impurity removal reaction kettle, then add sulfuric acid with a liquid-solid ratio of 5:1 and a concentration of 30%, control the heating temperature at 70°C, and control the speed of the mixer at 200r / min; the reaction time is 5 hours, The reaction is carried out under normal pressure. After the reaction is over, stop heating and stirring, use a vacuum pump to filter, rinse with hot water for 3 times after filtering; add the sulfuric acid residue after washing to the silver removal reaction kettle, enter step 2, and open the filter while filtering. The induced draft fan opens the spray tower, and at the same time opens the upper exhaust valve of the impurity removal reactor; step 1, the impurity removal filtrate is adsorbed by activated ca...

Embodiment 3

[0036] The following steps are carried out, take gold mud 185g, the main components of gold mud: Au 22.21% Ag 56.95%, Cu 0.019%, Pb 0.32%, Fe 0.58%;

[0037] step 1:

[0038] Dry and break the gold mud of the above grade into the impurity removal reaction kettle, then add sulfuric acid with a liquid-solid ratio of 6:1 and a concentration of 25%, control the heating temperature at 65°C, and control the speed of the mixer at 250r / min; the reaction time is 4 hours, The reaction is carried out at normal pressure, stop heating and stirring after the reaction is over, filter with a vacuum pump, rinse with hot water for 3 times after filtering; add the sulfuric acid slag after washing to the silver removal reactor, enter step 2, and open the starter while filtering. Fan, open the spray tower, and at the same time open the upper exhaust valve of the impurity removal reactor; step 1, the impurity removal filtrate is adsorbed by activated carbon, and the acid waste water is neutralized ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com