Production of regenerated tabacco slice by microwave leaching technology

A technology of reconstituted tobacco and ultrasonic wave, which is applied in the direction of preparing tobacco, tobacco, and treating tobacco, etc. It can solve the problems of large energy consumption and high requirements for the size of tobacco sheets, and achieves short extraction time, high content of active ingredients in the extract, and high content of active ingredients. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

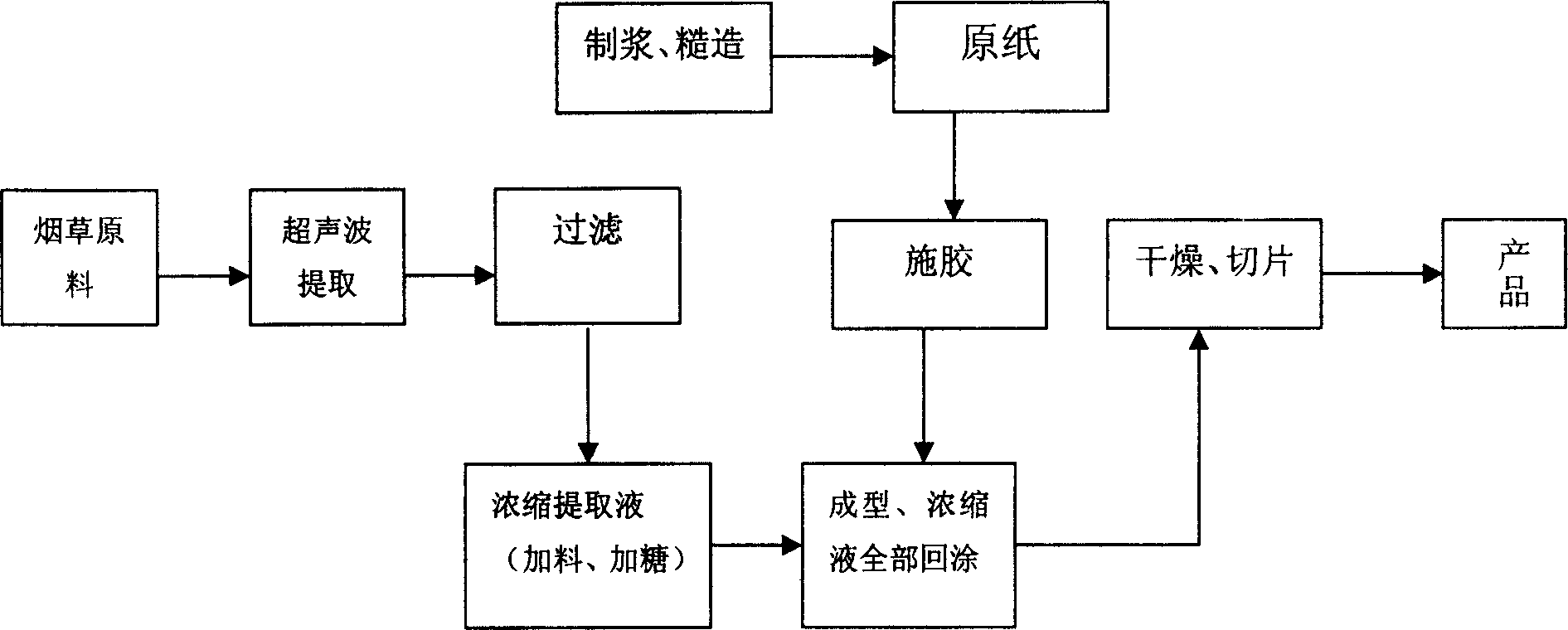

Method used

Image

Examples

Embodiment 1

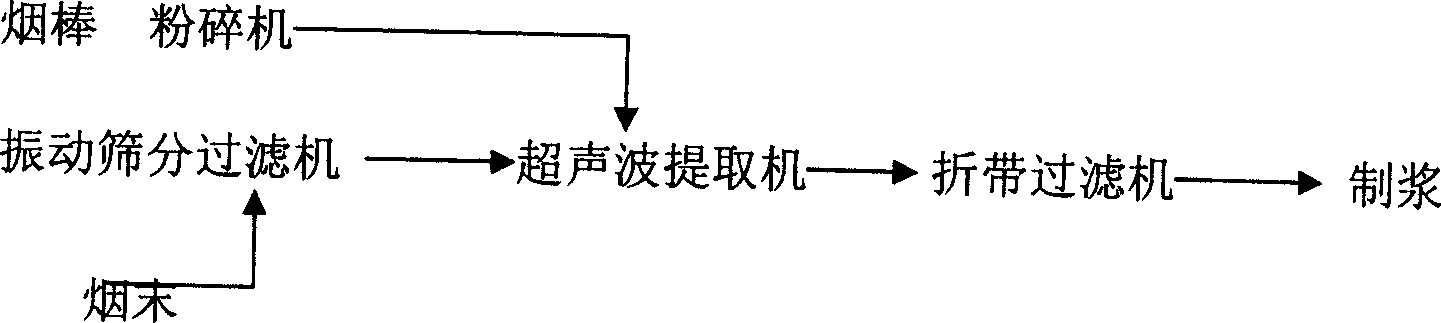

[0024] Take the crushed tobacco stick and the smoke powder less than 2mm after impurity removal treatment and mix them in the ratio of 2:3 (total amount 400Kg), add water according to the solid-liquid ratio of 1:10, and put them into the ultrasonic extraction equipment together ( The place of origin of the ultrasonic extraction equipment is Ningbo, the model is: CTD-SC-5000, the same below), the ultrasonic frequency is 25kHz, the sound intensity is 20W / cm 2 Within the range of extraction at room temperature for 20 minutes, enter the folded belt suction filter to separate the solid and liquid. Put the solid part into the paper making process, and copy it to 55g / m 2 Reconstituted tobacco; press dehydration and drying, concentrate the liquid extracted by ultrasonic extractor to the same weight of dry material, and add seasoning (cocoa tincture, maltol, ratio: 0.007%), sugar material (ratio: 7%) After seasoning and all back coating on the reconstituted tobacco, when the moisture ...

Embodiment 2

[0027] Take the crushed tobacco stick and the smoke powder less than 2mm after impurity removal treatment and mix them in a ratio of 3:2 (total amount 400Kg), add water at a liquid ratio of 1:8, and put them into an ultrasonic extraction device together. The frequency is 20kHz, the sound intensity is 30W / cm 2 Within the range of extraction at room temperature for 30 minutes, enter the folded belt suction filter to separate the solid and liquid. Put the solid part into the paper making process and make 50g / m 2 Reconstituted tobacco; press dehydration and drying, concentrate the liquid extracted by the ultrasonic extractor to the same weight of the dry material, and add seasoning (cocoa tincture, composite natural flavor raw material ratio: 0.008%), sugar material (ratio: 6%) ) etc. for seasoning and all back-coated on the reconstituted tobacco, dried to a moisture content of 9-12% and packaged in slices.

Embodiment 3

[0029] Take the crushed tobacco stick and the smoke powder less than 2mm after the impurity removal treatment and mix them in the ratio of 1:1 (total amount 400Kg), add water at the liquid ratio of 1:6, and put them into the ultrasonic extraction equipment together. The frequency is 35kHz, the sound intensity is 40W / cm 2 Within the range of 45 ° C for 20 minutes, enter the folded belt suction filter to separate the solid and liquid. Put the solid part into the paper making process, and copy it to 60g / m 2 Reconstituted tobacco; press dehydration and drying, concentrate the liquid extracted by the ultrasonic extractor to the same weight as the dry material, and add seasoning (cocoa tincture, maltol, vanillin, compound natural flavor raw materials, ratio: 0.004-0.015 %), sugar (proportion: 5%), etc. are seasoned and all are back-coated on the reconstituted tobacco, dried to a moisture content of 8-10%, sliced and packaged.

[0030] The flakes prepared in the above examples ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com