Field radiation calibration and calibrator for large-bore photoelectric system

A technology of radiation calibration and photoelectric system, which is applied in the field of radiation calibration of large-aperture photoelectric radiation measurement system, can solve problems such as failure to meet radiation calibration requirements, failure to meet calibration requirements, radiation energy attenuation, etc., and achieve light weight, The effect of low power consumption and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

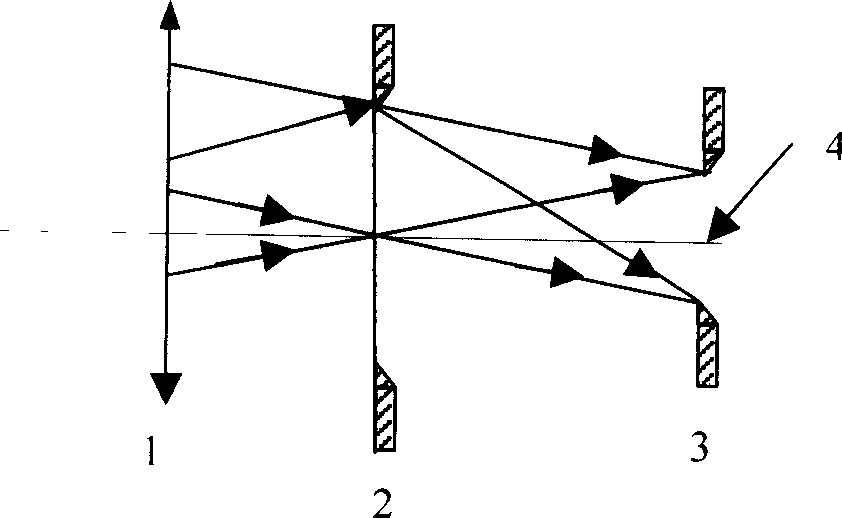

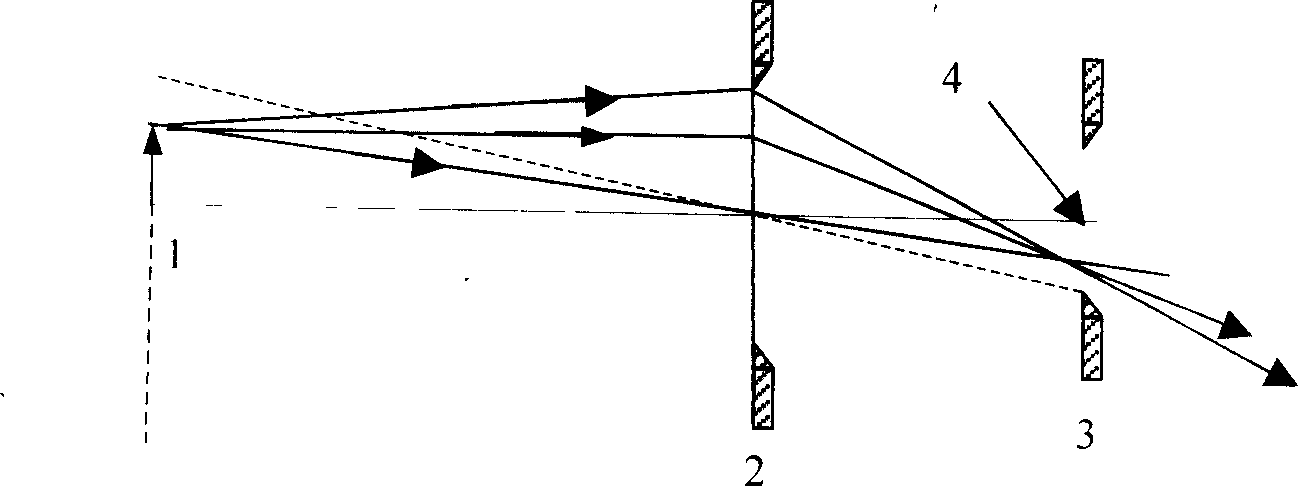

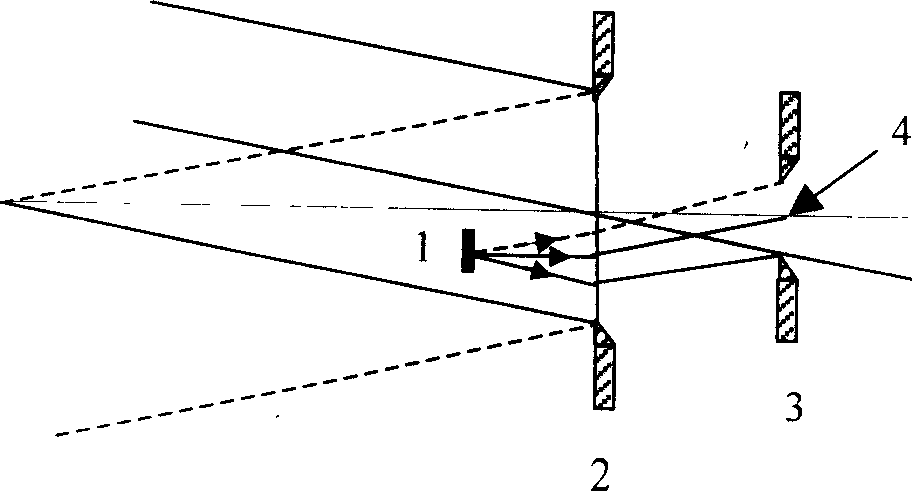

[0030] Embodiment 1: as Figure 4 Shown: Before calibrating the optoelectronic system, the reference radiometer 6 is firstly calibrated with the standard radiation source 5 to obtain the responsivity 7 of the reference radiometer 6, and then the reference radiometer 6 is connected to the radiation calibration illumination source 8 The device 22 is docked, and the output radiance B of the radiation calibration illumination source 8 is measured λ ; When calibrating the photoelectric system, according to Figure 5 The on-site radiation calibration is implemented as shown, the radiation calibration illumination source 8 is installed on the multi-dimensional adjustment bracket, so that it can move along the radial direction and the circumferential direction of the optical aperture of the photoelectric system 9 to be calibrated, and the photoelectric system to be calibrated can be adjusted. Full aperture radiometric calibration. Place the radiation calibration illumination source ...

Embodiment 2

[0050] Change the cavity-type radiation source in the infrared band of the radiation calibration illumination source to a light source in the visible light band, and then coat the working surfaces of the primary mirror 13 and the secondary mirror 14, the first mirror 17 and the first primary mirror 18 with a high-reflection film in the visible light band , the detector 10 adopts a visible light band detector, and other components are the same as those in Embodiment 1, then the present invention can perform radiation calibration on a large aperture photoelectric system in the visible light band.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com