Loaded type silicon hydrogenation catalyst and its synthetic method

A technology of hydrosilation reaction and synthesis method, which is applied in the direction of physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, silicon organic compounds, etc., which can solve the difficulty of catalyst separation, non-recyclable utilization, high catalyst cost, etc. problems, to achieve the effects of easy control, wide range of applications, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

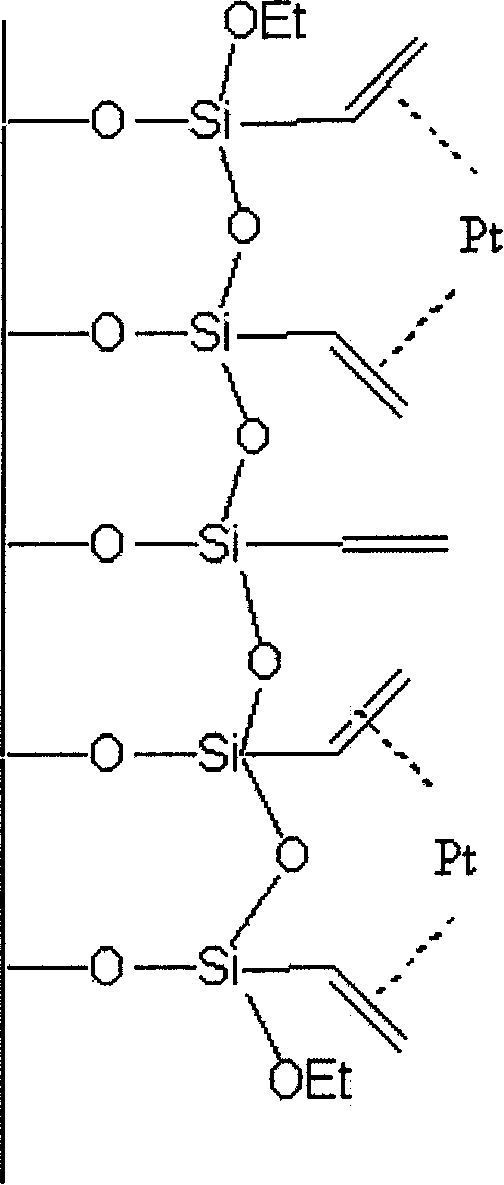

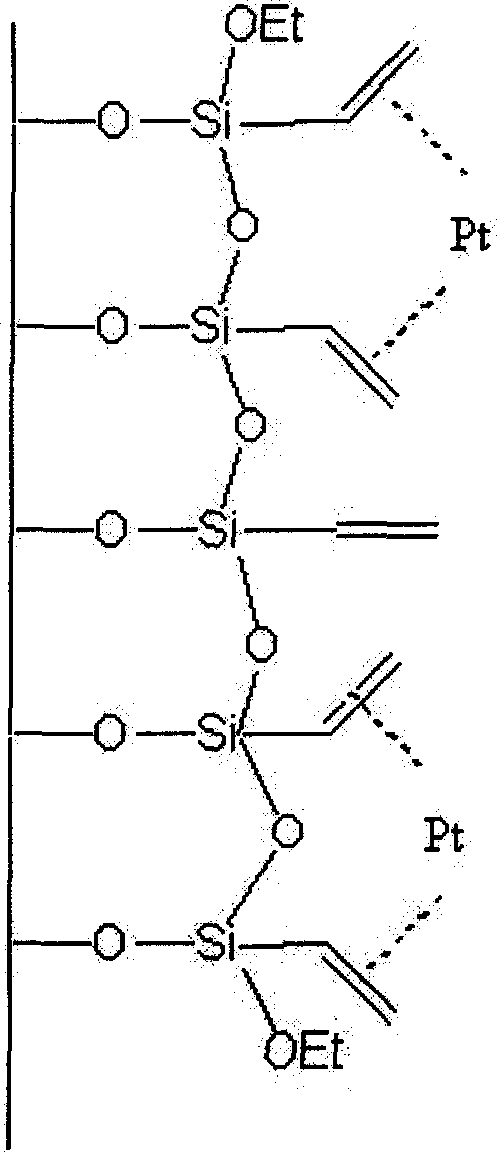

Image

Examples

Embodiment 1

[0019] Embodiment 1: the coupling treatment of catalyst carrier (with silica as carrier)

[0020] In a 250mL reactor equipped with a nitrogen inlet and outlet and a stirring device, add 6.0g of fumed silica and 140mL of toluene, stir at room temperature for half an hour under nitrogen protection, add 6.0g of vinyltriethoxysilane, heat at 110°C The reaction was stirred at reflux for 24 hours. Filtrate to obtain a slightly viscous white powder, dry it, and activate the reaction at a temperature of 150° C. and a pressure of 26 Pa for 5 hours. Cool and grind, wash with acetone, and dry at 120°C / 26Pa to constant weight to obtain a non-sticky white powder.

Embodiment 2

[0021] Embodiment 2: the coupling treatment of catalyst carrier (with glass fiber as carrier)

[0022] In a 250mL reactor protected by nitrogen, add 2.0g of glass fiber and 100mL of xylene, add 100mL of an aqueous solution with a mass concentration of 1.0% vinyltriethoxysilane, heat, and reflux at 140°C for 12 hours. After stopping the reaction The glass fibers were taken out and activated for 5 hours at a temperature of 150° C. and a pressure of 26 Pa. Then wash with acetone and dry at 120°C / 26Pa to constant weight.

Embodiment 3

[0023] Embodiment 3: the coupling treatment of catalyst carrier (with silica as carrier)

[0024] In a 250mL reactor equipped with a nitrogen inlet and outlet and a stirring device, add 6.0g of fumed silica and 150mL of benzene, stir at room temperature for half an hour under nitrogen protection, add 4.0g of vinyltriethoxysilane, heat at 30°C The reaction was stirred at reflux for 3 hours. Filter and activate the reaction for 5 hours at a temperature of 150° C. and a pressure of 26 Pa. Cool and grind, wash with acetone, and dry at 120°C / 26Pa until constant weight to obtain a white powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com