Adhesive agent for circuit member connection, circuit board and its producing method

A technology for circuit components and adhesives, which is applied in semiconductor/solid-state device manufacturing, circuits, electrical components, etc., and can solve problems such as poor conduction, increased connection resistance, and adhesive peeling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

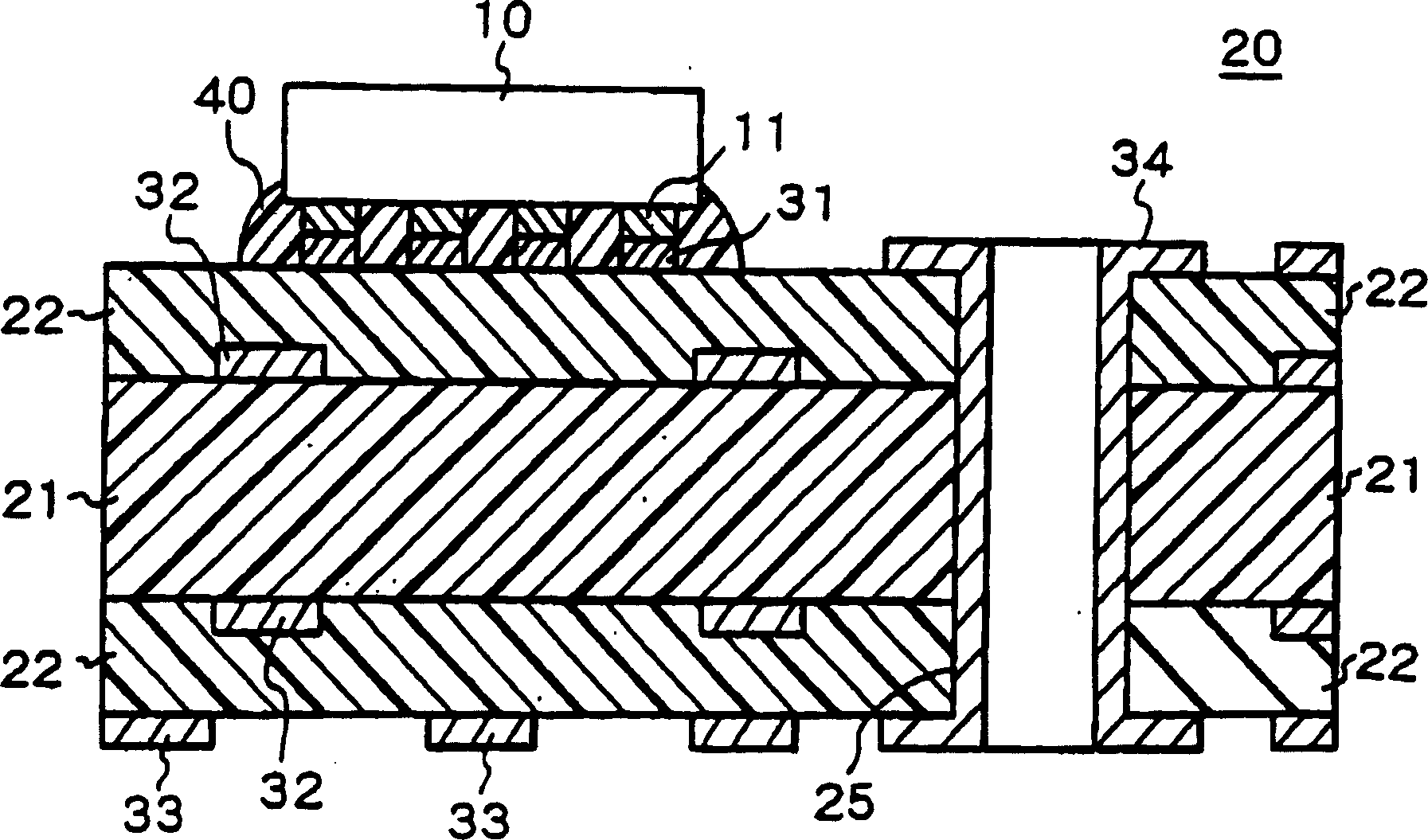

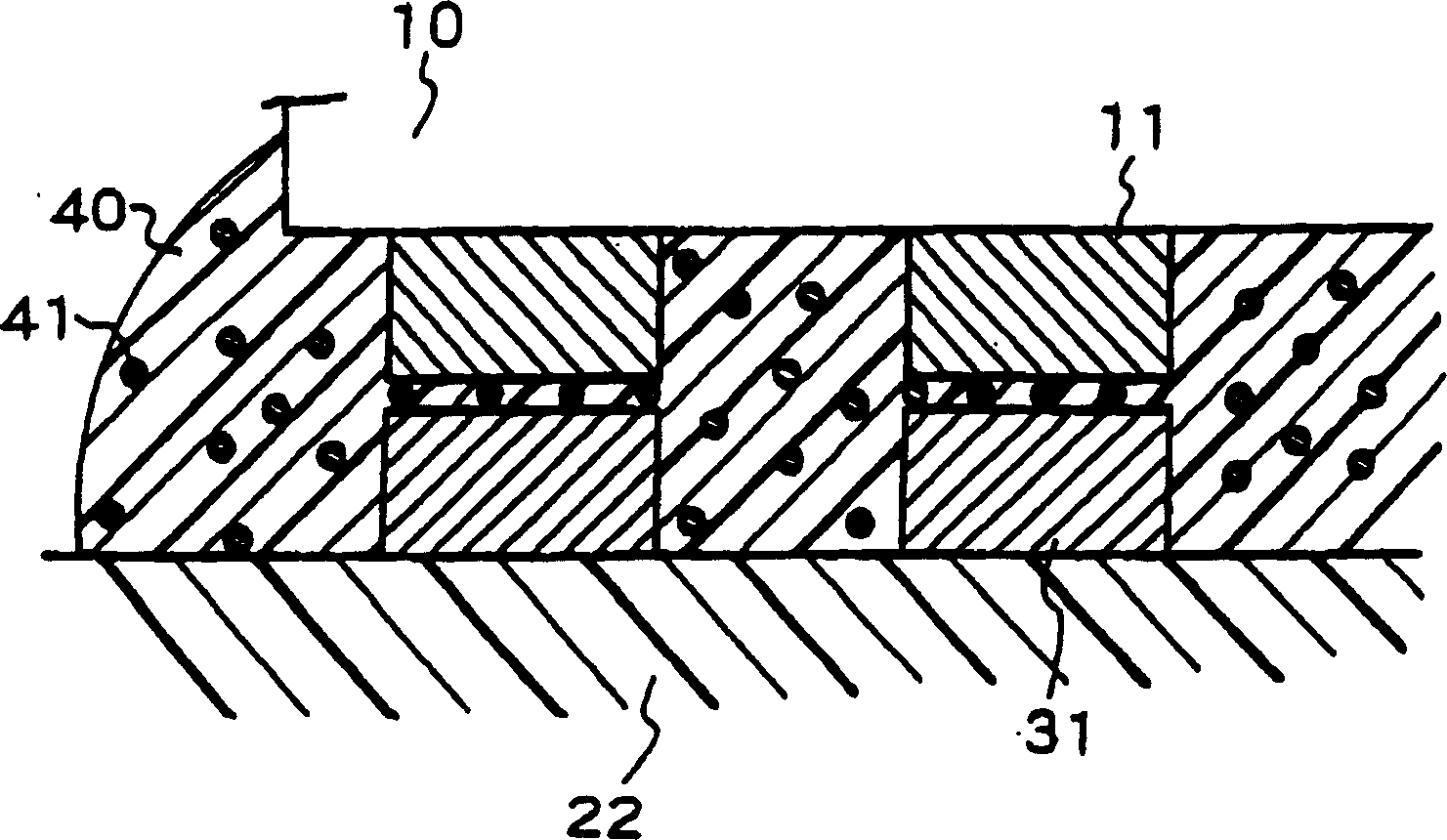

Image

Examples

Embodiment 1

[0074] Acrylic rubber obtained by copolymerizing 50 g of phenoxy resin, butyl acrylate (40 parts), ethyl acrylate (30 parts), acrylonitrile (30 parts) and glycidyl methacrylate (3 parts) ) 125g, dissolved in 400g of ethyl acetate to obtain a 30% solution.

[0075] Then, add 325 g of liquid epoxy resin (epoxy equivalent: 185) containing microcapsule type latent curing agent to the above solution, stir, add fused silica (average Particle size: 0.5 μm) 40 parts, and nickel particles (diameter: 3 μm 2% by volume) were dispersed therein to prepare a solution for film coating.

[0076] The film coating solution was applied on a release film (polyethylene terephthalate film treated with silicone, thickness: 40 μm) with a rubber roller, and dried at 100° C. for 10 minutes to form a thickness 45 μm adhesive film a. The modulus of elasticity at 40° C. of the adhesive resin composition in which fused silica and nickel particles were removed from the adhesive film a was 800 MPa as measu...

Embodiment 2

[0081] Acrylic rubber obtained by copolymerizing 50 g of phenoxy resin, butyl acrylate (40 parts), ethyl acrylate (30 parts), acrylonitrile (30 parts) and glycidyl methacrylate (3 parts) (molecular weight: 85 ten thousand) 175g, dissolved in 525g of ethyl acetate to obtain a 30% solution.

[0082] Then, add 275 g of liquid epoxy resin (epoxy equivalent: 185) containing microcapsule type latent curing agent to the above solution, stir, and add fused silica (average particle size) to 100 parts (weight) of the bonding resin composition. Diameter: 0.5 μm) 60 parts by weight, and nickel particles (diameter: 5 μm) 2% by volume were dispersed therein to prepare a film coating solution.

[0083] The film coating solution was applied on a release film (polyethylene terephthalate film treated with silicone, thickness: 40 μm) with a rubber roller, and dried at 100° C. for 10 minutes to form a thickness of 45 μm. The adhesive film b. The elastic modulus at 40° C. of the adhesive resin c...

Embodiment 3

[0088]Acrylic rubber obtained by copolymerizing 50 g of phenoxy resin, butyl acrylate (40 parts), ethyl acrylate (30 parts), acrylonitrile (30 parts) and glycidyl methacrylate (3 parts) (molecular weight: 85 Ten thousand) 100g was dissolved in ethyl acetate 350g to obtain a 30% solution.

[0089] Then, add 350 g of liquid epoxy resin (epoxy equivalent: 185) containing a microcapsule type latent curing agent to the above solution, stir, and add fused silica (average particle size) to 100 parts (weight) of the bonding resin composition. Diameter: 0.5 μm) 60 parts (by weight), and 5% (volume) of conductive particles forming the Au layer were dispersed on the surface of the polystyrene core material (diameter: 5 μm) to prepare a film coating solution.

[0090] The film coating solution was applied on a release film (polyethylene terephthalate film treated with silicone, thickness: 40 μm) with a rubber roller, and dried at 100° C. for 10 minutes to form a thickness 45 μm adhesive ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Insulation resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com