Method for processing monkshood

A technology for traditional Chinese medicine and aconite, which is applied in the field of processing traditional Chinese medicine aconite, can solve the problems of unfavorable wide application of aconite and high requirements for large-scale production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Soak the traditional Chinese medicine aconite product in water for 12 hours at normal temperature, take it out and dry it in the shade, and put it in an oven for drying at 200°C for 25 minutes to obtain the processed aconite product.

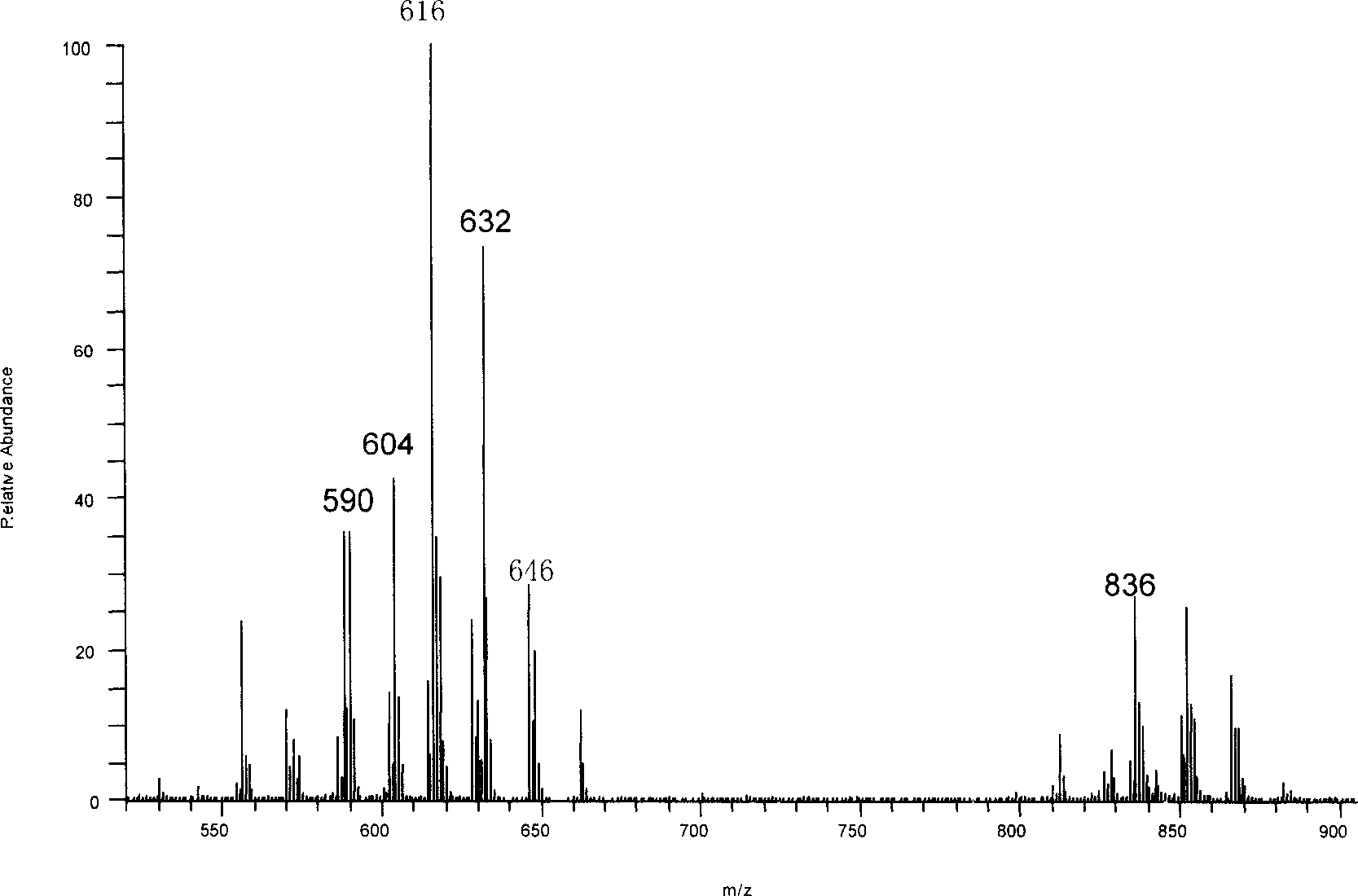

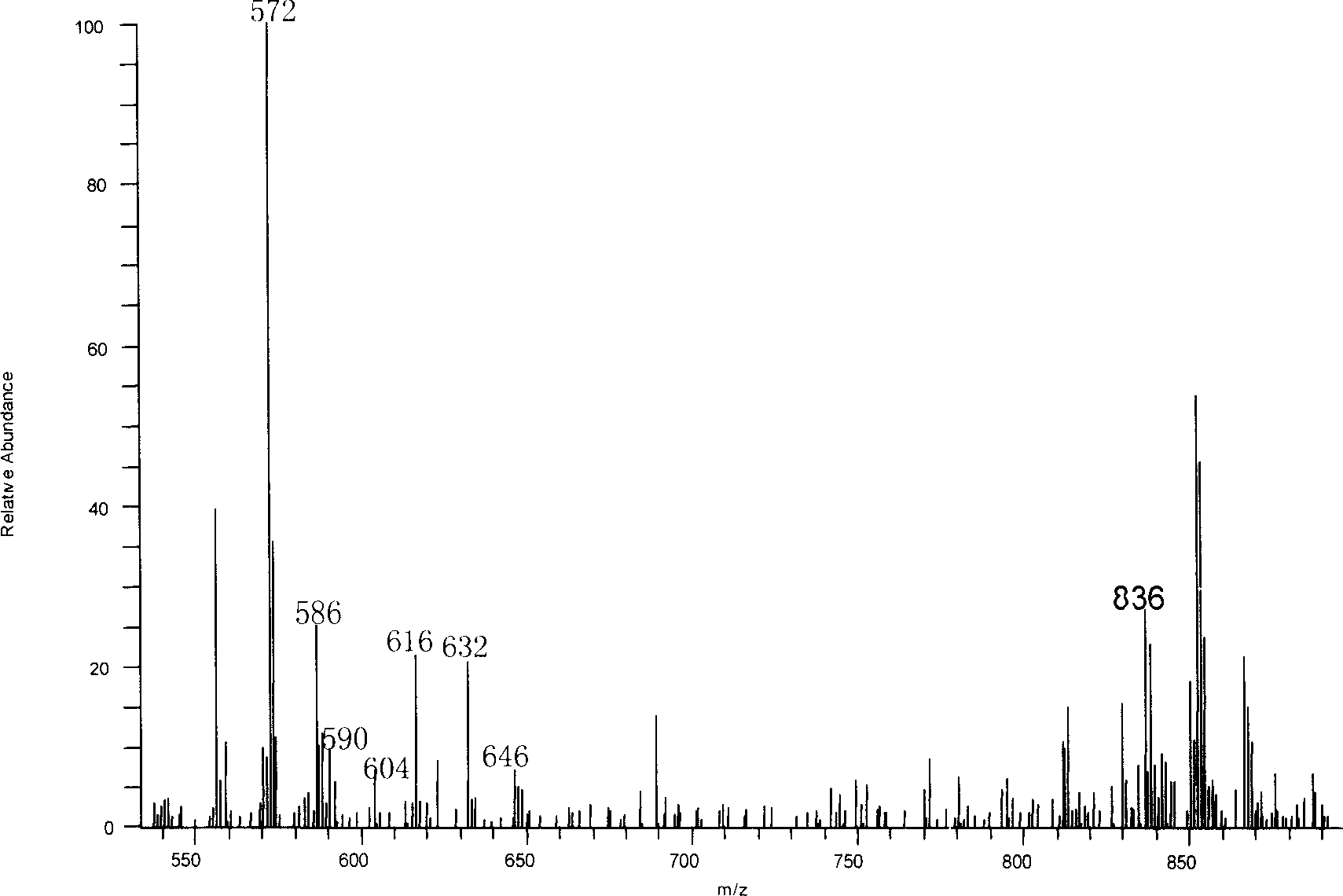

[0017] Get 0.4 grams of powder (passed through a No. 3 sieve) of processed aconite processed by the method, add an appropriate amount of 10% ammonia water, and use an appropriate amount of ether for ultrasonic extraction for 30 minutes. Diluted with methanol by electrospray mass spectrometry (ESIMS). The main components of aconitine in the processed products of traditional Chinese medicine are aconitine (m / z 646), mesoaconitine (m / z 632), hypoaconitine (m / z 616), benzoyl mesoaconitine (m / z 590), benzoyl aconitamine (m / z 604), aconitine deacetate (m / z 586), mesoaconitine deacetate (m / z 572), 8-oil Acid-benzoyl aconitamine (m / z 836). After analysis by high performance liquid chromatography (HPLC), aconitine, mesoaconitine and hypoaconitin...

Embodiment 2

[0019] Soak the raw aconite product of traditional Chinese medicine in water for 18 hours at normal temperature, take it out and dry it in the shade, and dry it in an oven at 220°C for 20 minutes to obtain the processed aconite product.

[0020] Get 0.4 grams of powder (passed through a No. 3 sieve) of processed aconite processed by the method, add an appropriate amount of 10% ammonia water, and use an appropriate amount of ether for ultrasonic extraction for 30 minutes. Diluted with methanol by electrospray mass spectrometry (ESIMS). The main components of aconitine in the processed products of traditional Chinese medicine are aconitine (m / z 646), mesoaconitine (m / z 632), hypoaconitine (m / z 616), benzoyl mesoaconitine (m / z 590), benzoyl aconitamine (m / z 604), aconitine deacetate (m / z 586), mesoaconitine deacetate (m / z 572), 8-oil Acid-benzoyl aconitamine (m / z 836). After analysis by high performance liquid chromatography (HPLC), aconitine, mesoaconitine and hypoaconitine co...

Embodiment 3

[0022] Soak the raw aconite product of traditional Chinese medicine in water for 24 hours at room temperature, take it out and dry it in the shade, and dry it in an oven at 240°C for 15 minutes to obtain the processed aconite product.

[0023] Get 0.4 grams of powder (passed through a No. 3 sieve) of processed aconite processed by the method, add an appropriate amount of 10% ammonia water, and use an appropriate amount of ether for ultrasonic extraction for 30 minutes. Diluted with methanol by electrospray mass spectrometry (ESIMS). The main components of aconitine in the processed products of traditional Chinese medicine are aconitine (m / z 646), mesoaconitine (m / z 632), hypoaconitine (m / z 616), benzoyl mesoaconitine (m / z 590), benzoyl aconitamine (m / z 604), aconitine deacetate (m / z 586), mesoaconitine deacetate (m / z 572), 8-oil Acid-benzoyl aconitamine (m / z 836). After analysis by high performance liquid chromatography (HPLC), aconitine, mesoaconitine and hypoaconitine coul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com