Method for repairing a blade of a one-piece bladed disc of aturbine engine and a test piece for implementing the method

A test piece, turbine technology, applied in turbines, blade support elements, optical testing flaws/defects, etc., can solve the problems of mechanical properties decline in the welding area, difficulty in welding, and difficulty in standardization, and achieve the effect of large stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

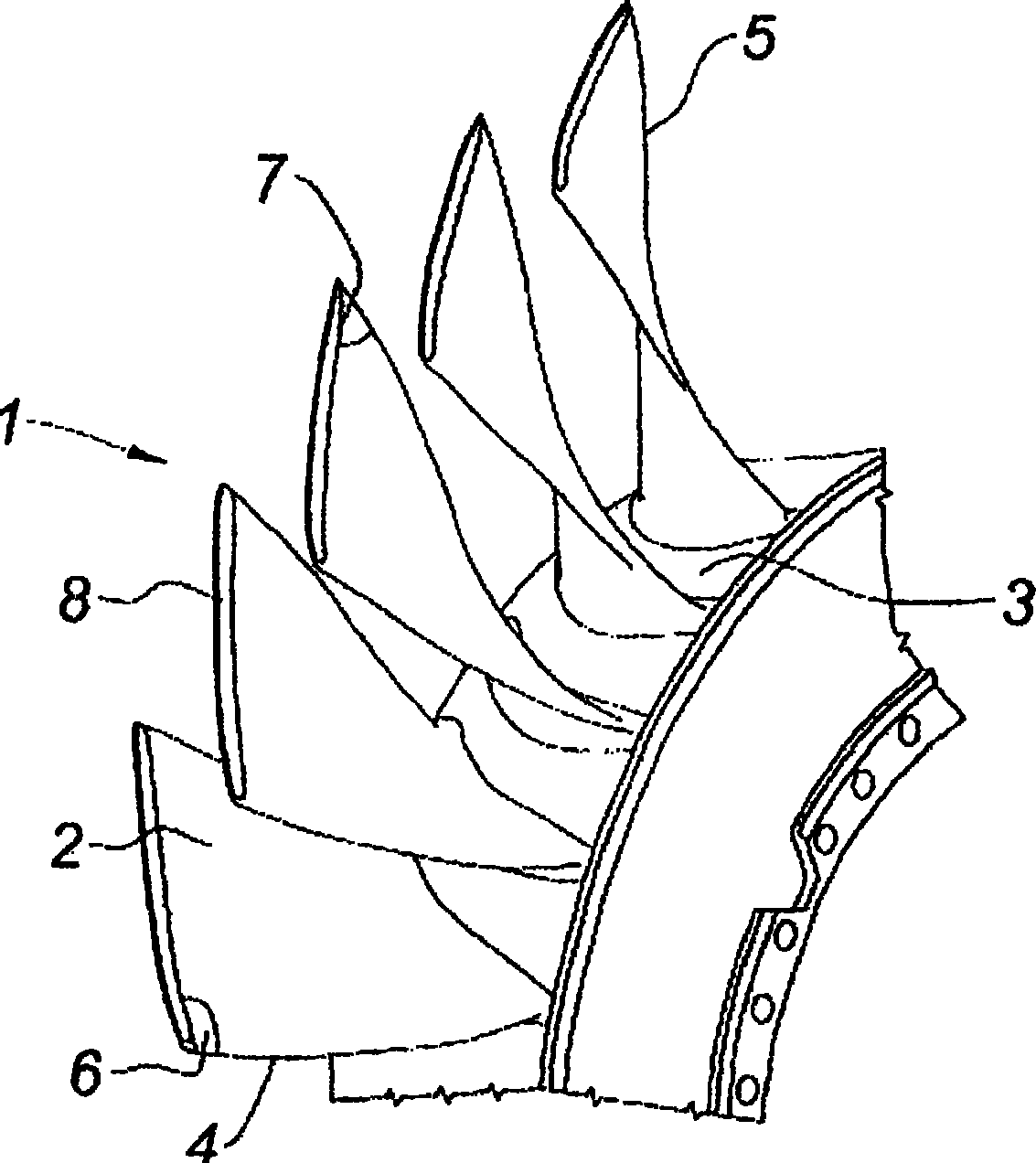

[0033] refer to figure 1 , the inventive method involves repairing a blade 2 extending radially from the circumference of the edge 3 of a single blisk 1 (integral blisk 1), here made of Ti17 titanium. The blade has a damaged area due to impact or wear. Areas susceptible to damage are the leading edge 4, the trailing edge 5, the leading edge corner 6, the trailing edge corner 7 and the line of the blade tip 8, where a portion of thinner thickness, the sealing lip, is formed in a known manner.

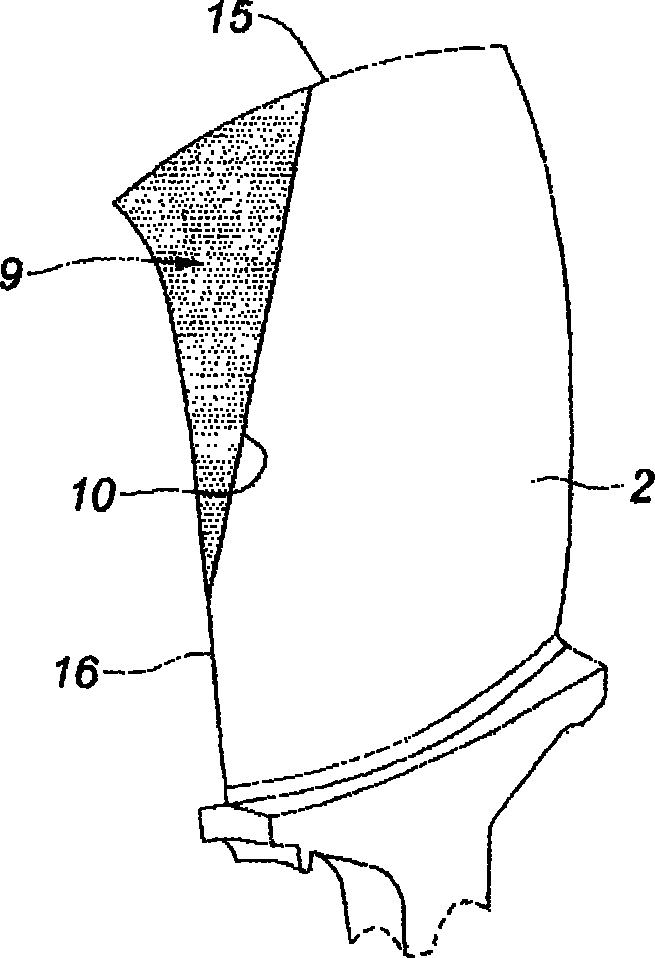

[0034] Predefined on the blade is a standardized section in which the damaged section to be repaired is located, corresponding to the section of the blade that is cut from the blade for repair. The first step of the method is to check whether the damaged area of the blade is located in this area. figure 2 The blade 2 and such standardized regions 9 are illustrated, shown in grey. This portion 9 is here the corner of the leading edge of the blade 2 .

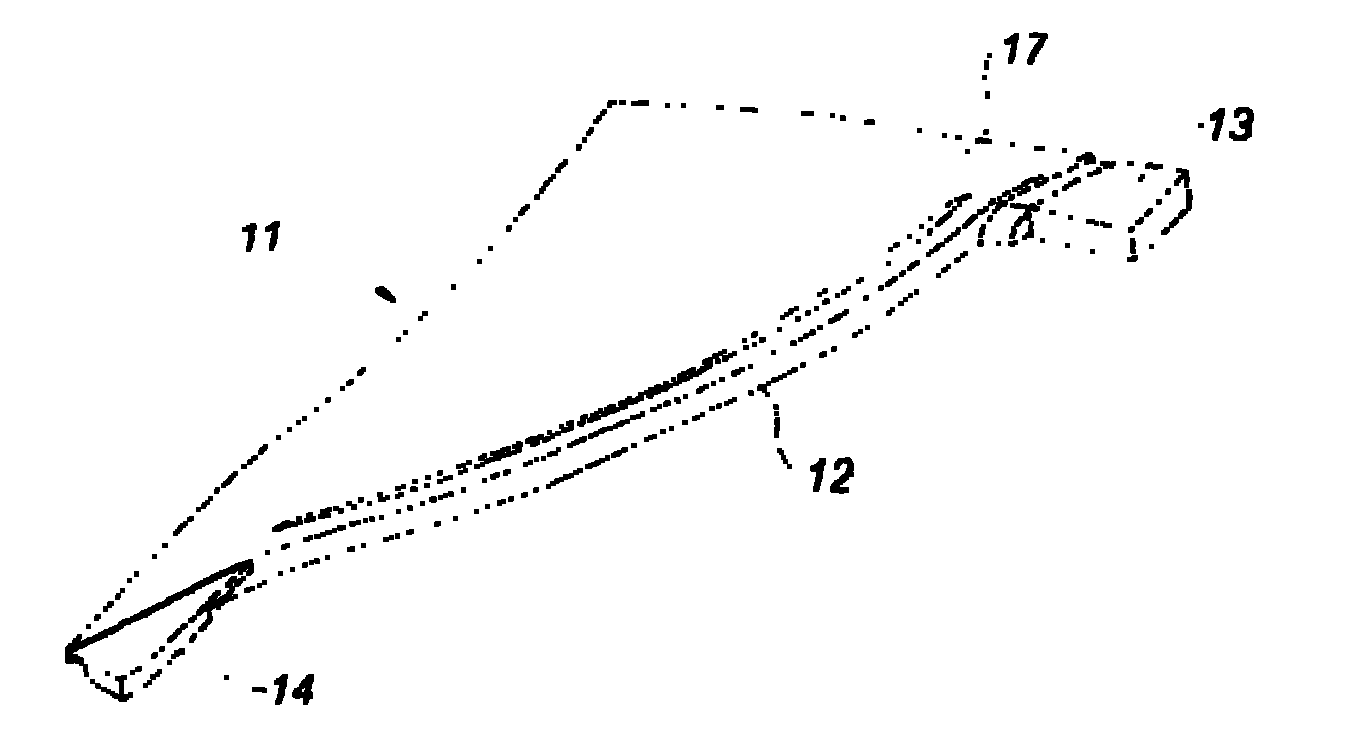

[0035] If this is the case, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com