Preparation method of manganese-cobalt-nickel thin film heat-sensitive material

A heat-sensitive material, manganese-cobalt-nickel technology, applied in metal material coating process, liquid chemical plating, coating and other directions, can solve the problem of insufficient service life and reliability of devices, poor uniformity, repeatability and stability, and finished device products. problems such as low rate, to achieve the effect of small substrate selection limitations, good uniformity, and dense material structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] A best example obtained through experimental research is provided below, and the present invention is further described in detail.

[0021] Best practice:

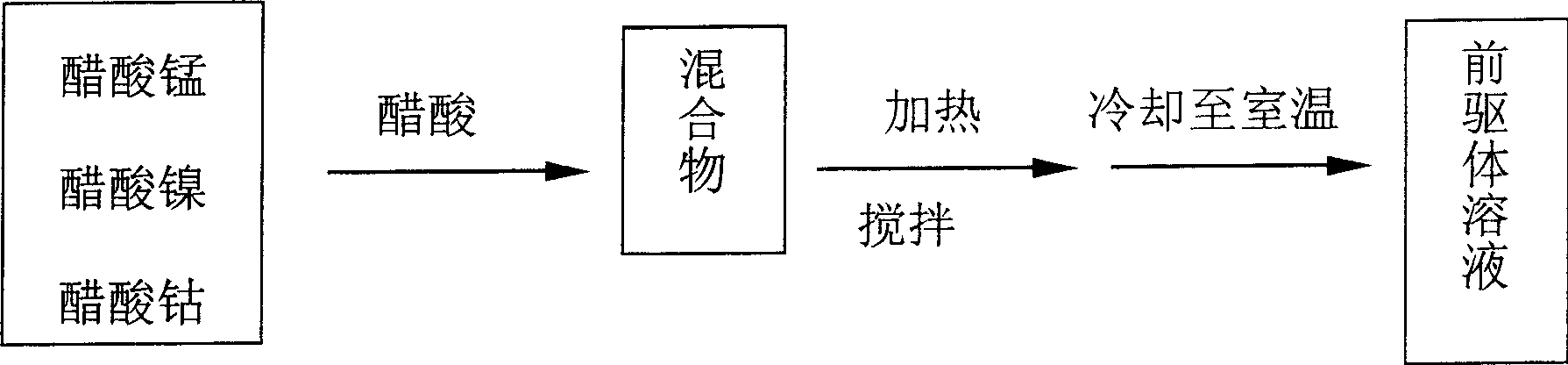

[0022] Acetate proportioning Mn: Co: Ni=52: 32: 16 (atomic ratio), solvent uses glacial acetic acid, and its content only needs to make acetate dissolve, and the size of solvent content is relevant with the single-layer thickness of even glue film.

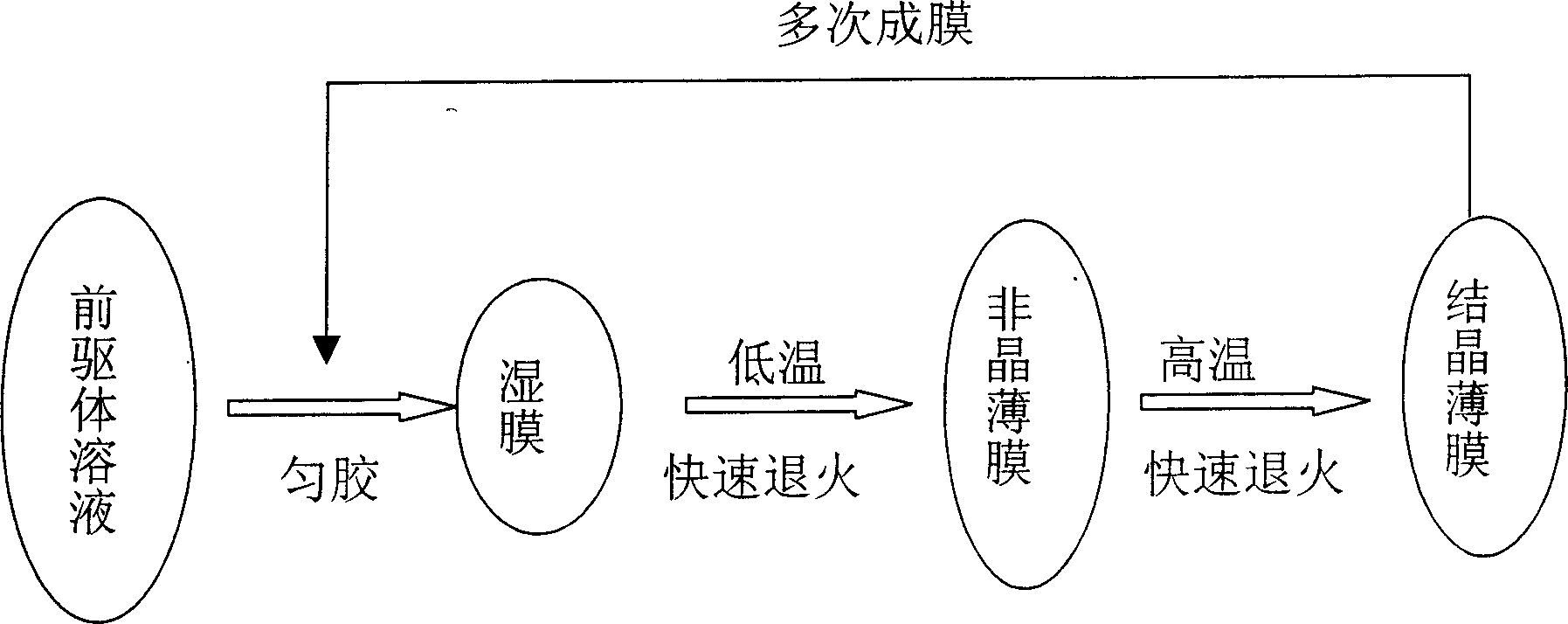

[0023] The annealing conditions are: heating up to 180°C for 10 seconds and maintaining for 300 seconds;

[0024] The temperature was raised from 180°C to 500°C in 10 seconds and held for 400 seconds.

[0025] The final temperature coefficient of resistance of the thin film is as high as 3.4% / °C.

[0026] In the preparation process of the present invention, the quality of the prepared precursor solution will directly affect the quality of the grown film. When selecting raw materials, the influence on the human body is considered, and non-toxic or low-toxic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com