Production equipment of polyolefin coextrusion film powder liquid bicavity transfusion soft bag

A technology of infusion soft bags and complete sets of equipment, which is applied in the field of pharmaceutical equipment, can solve problems such as medical accidents, drug pollution, and unreachable curative effects, and meet the requirements of welding strength stability, product qualification rate improvement, and virtual welds. The effect of stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0075] The present invention will be further described below in conjunction with the accompanying drawings of the embodiments.

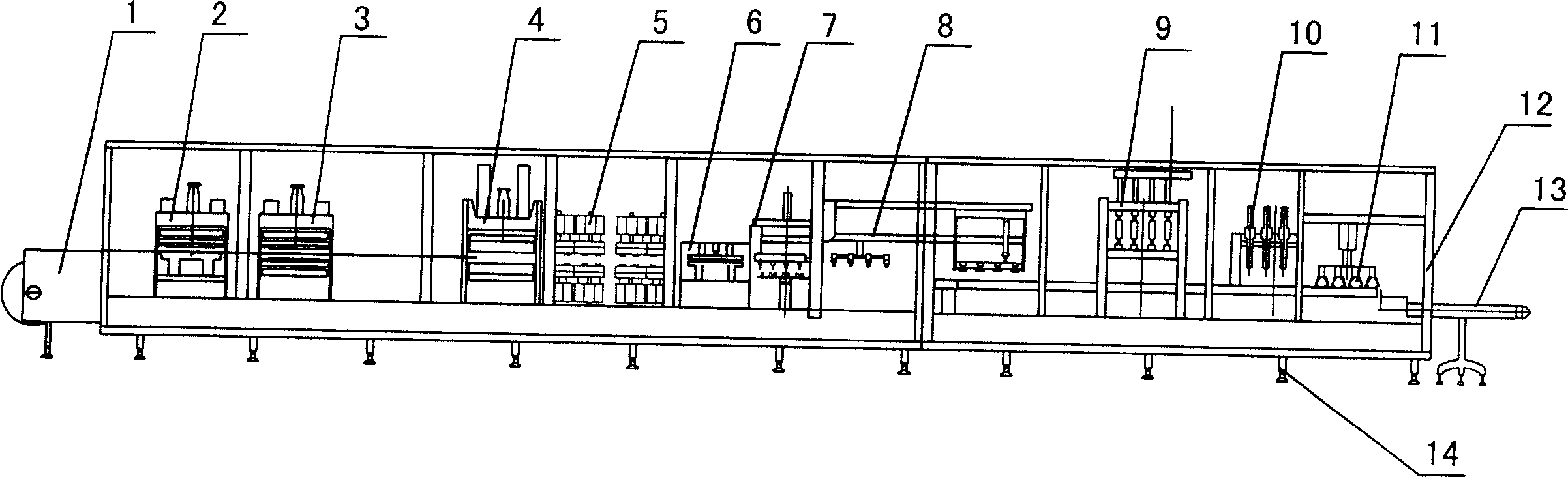

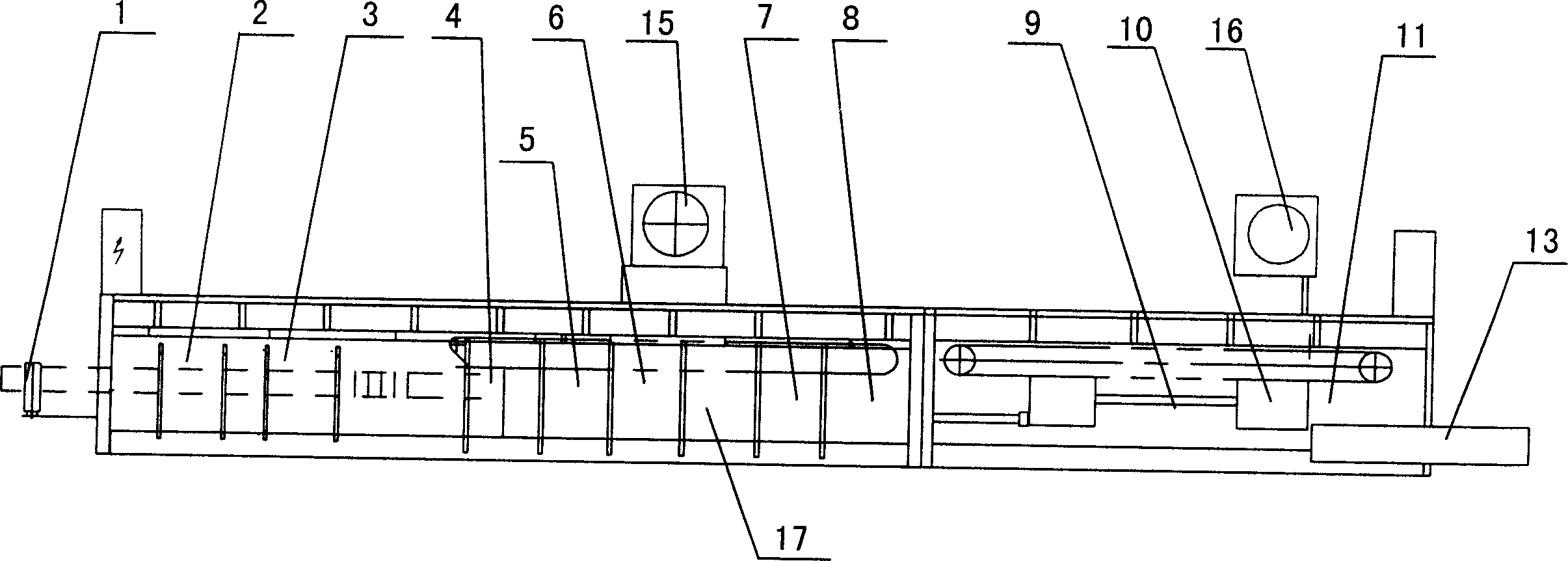

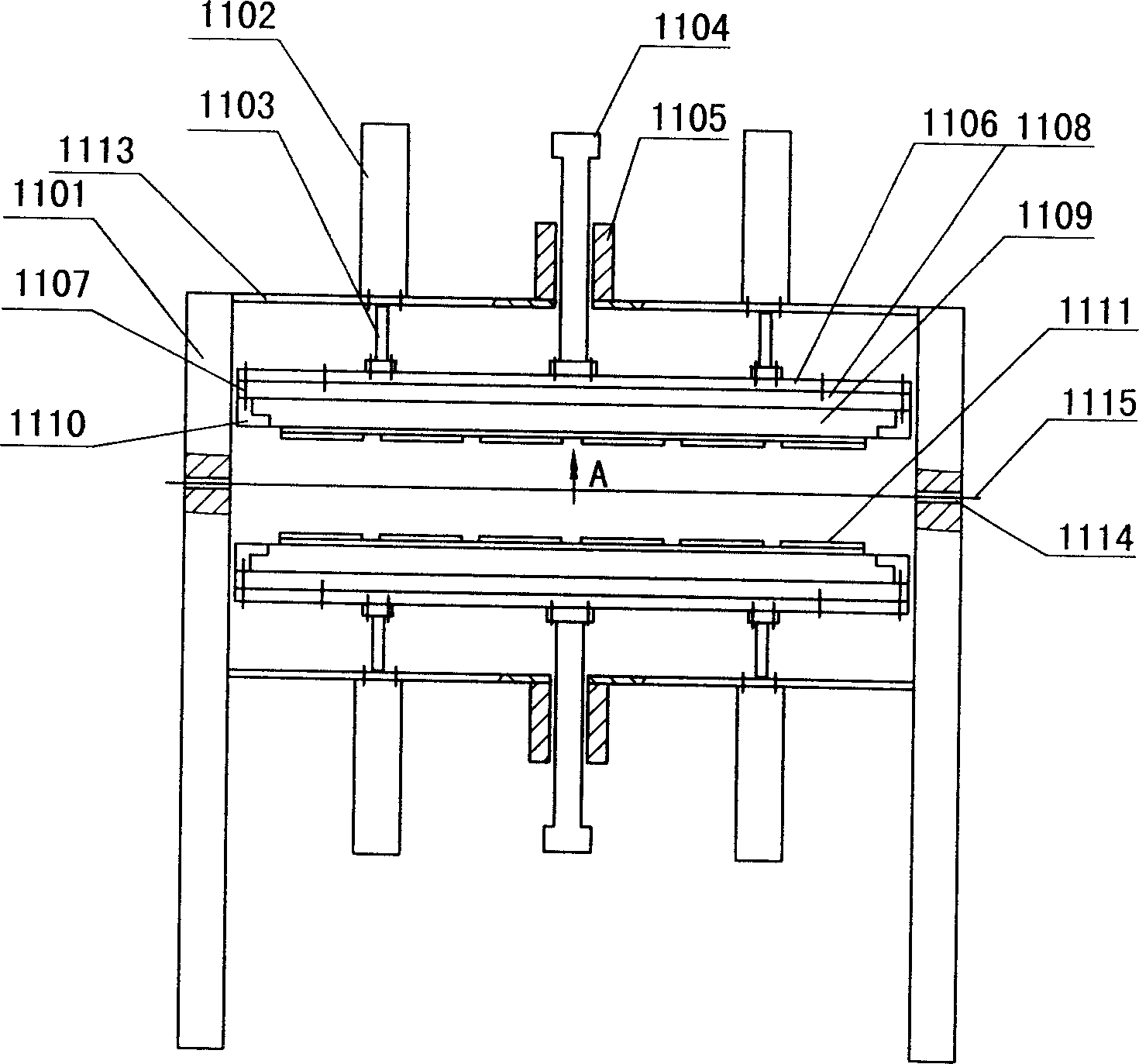

[0076] Such as figure 1 , 2 As shown, it is the bag-making and liquid filling machine in the non-PVC film powder-liquid double-chamber infusion soft bag-making filling machine of the present invention, including a bag-making mechanism and a liquid filling mechanism, and the bag-making mechanism includes an upper film Mechanism 1, printing mechanism 2, false welding mechanism 3, bag body heat sealing mechanism 4, bag body cooling mechanism 6, nozzle tube preheating mechanism, nozzle tube welding mechanism 5 and waste edge removal mechanism, that is, bag separation mechanism 7, liquid filling The mechanism includes a filling mechanism 9, a sealing welding mechanism 10 and a bag body output mechanism 11; the bag making mechanism and the liquid filling mechanism are respectively provided with an endless transmission timing belt, and the timing belt is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com