Method for preparing fibers from waste and timber

A kind of wood and waste technology, which is applied in the field of fiber preparation by using waste wood, can solve the problems of fiber shape damage and unsuitability, and achieve the effects of alleviating supply shortage, reducing cutting power, and excellent fiber performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

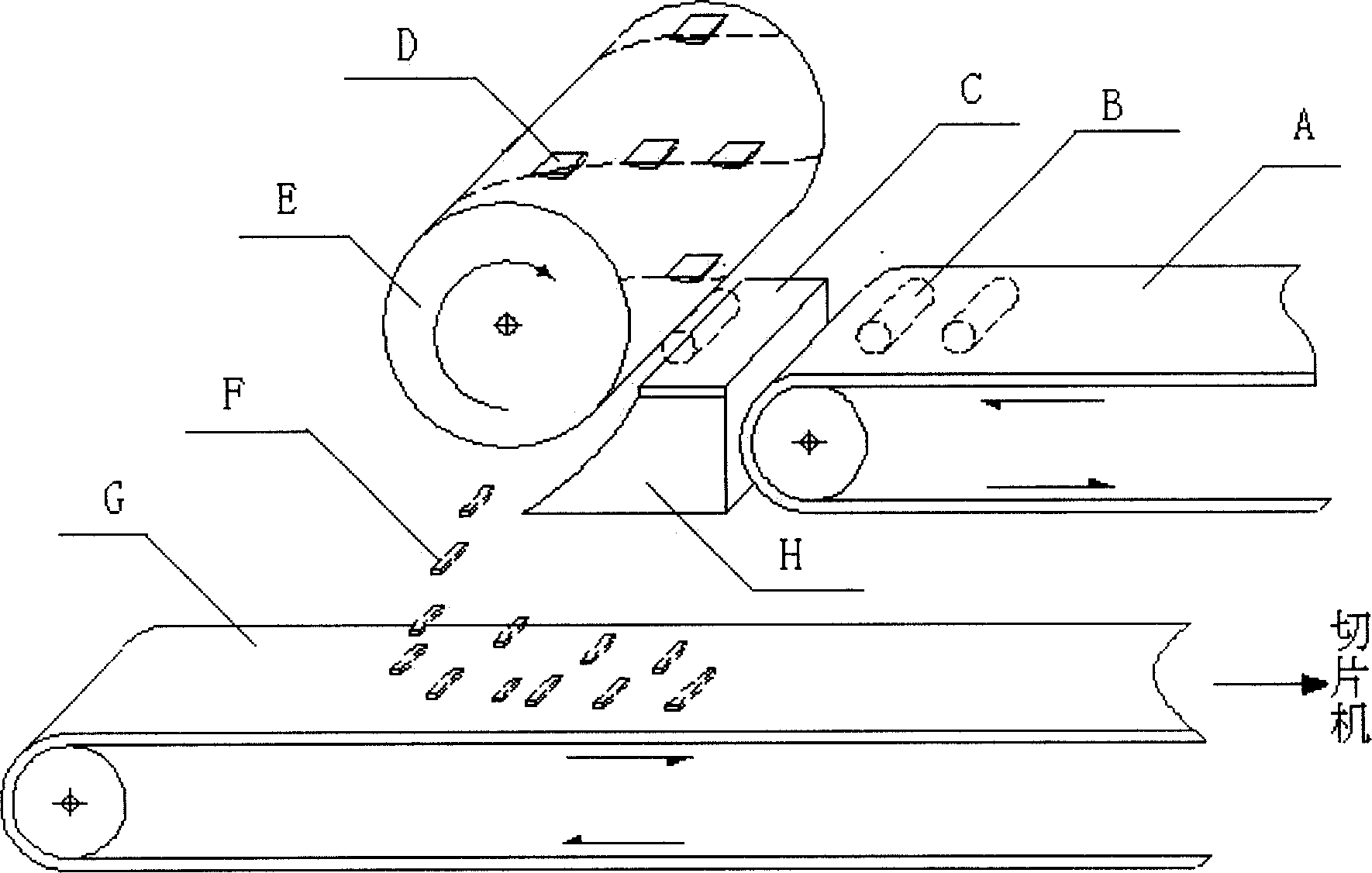

[0035] Example 1: Fabrication of fibers using recycled solid wood building components

[0036] The recovered solid wood building components B are sent to the primary crusher by the waste wood conveyor A, and the metal bumps D distributed in a spiral shape on the main shaft E are rotated by the primary crusher to cooperate with the bottom knife C on the bottom knife bracket H of the primary crusher. Cut the recycled solid wood building components B horizontally to form a strip unit F; when the recovered solid wood building components are processed into strip units, the attached metal parts and cement impurities basically fall off (the residual metal parts are transported to the chips after the wooden strips are transported to the chips) The metal parts that fall off are collected by magnetic separation and recycled, and other impurities are collected separately; the strip-shaped units processed by the recycled solid wood building components are further transported to the chipper...

Embodiment 2

[0037] Example 2: Fabrication of fibers from recycled panel furniture (medium density fibreboard)

[0038] The recovered panel furniture B is sent to the primary crusher by the waste wood conveyor A, and the metal bump D on the main shaft E is rotated by the primary crusher, and the metal bump D on the main shaft E is matched with the bottom knife C on the bottom knife bracket H of the primary crusher. Cut the recycled panel furniture B to form a strip unit F; when the recovered panel furniture is processed into a strip unit, the attached metal parts and cement impurities basically fall off (the residual metal parts are transported to the chipper during the process of transporting the wooden strips to the chipper) manually picked out); the fallen metal parts are collected by magnetic separation and recycled, and other impurities are collected separately; the strip units processed by the recycled solid wood building components are further transported to the chipper by the strip un...

Embodiment 3

[0039] Example 3: Preparation of fibers using recycled cement formwork

[0040] The recycled poplar multi-layer plywood cement formwork B with a thickness of 12-18mm is sent to the primary crusher by the waste wood conveyor A, and the metal bumps D distributed in a spiral shape on the main shaft E are rotated by the primary crusher to cooperate with the bottom of the primary crusher. The bottom knife C on the knife bracket H cuts the recycled cement formwork B horizontally to form a strip unit F; when the recovered cement formwork is processed into a strip unit, the attached metal parts and cement impurities basically fall off (residual metal parts Manually picked out during the process of transporting wood strips to the chipper); the fallen metal parts are collected by magnetic separation and recycled, and other impurities are collected separately; the strip units processed by the recovered cement formwork are sent by the strip unit conveyor It is further transported to the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com