Method for preparing Nano line of titania, and application of the prepared Nano line of titania

A titanium dioxide and nanowire technology, applied in the direction of titanium oxide/hydroxide, titanium dioxide, nanostructure manufacturing, etc., to achieve wide application prospects, low production cost, and good powder crystallinity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

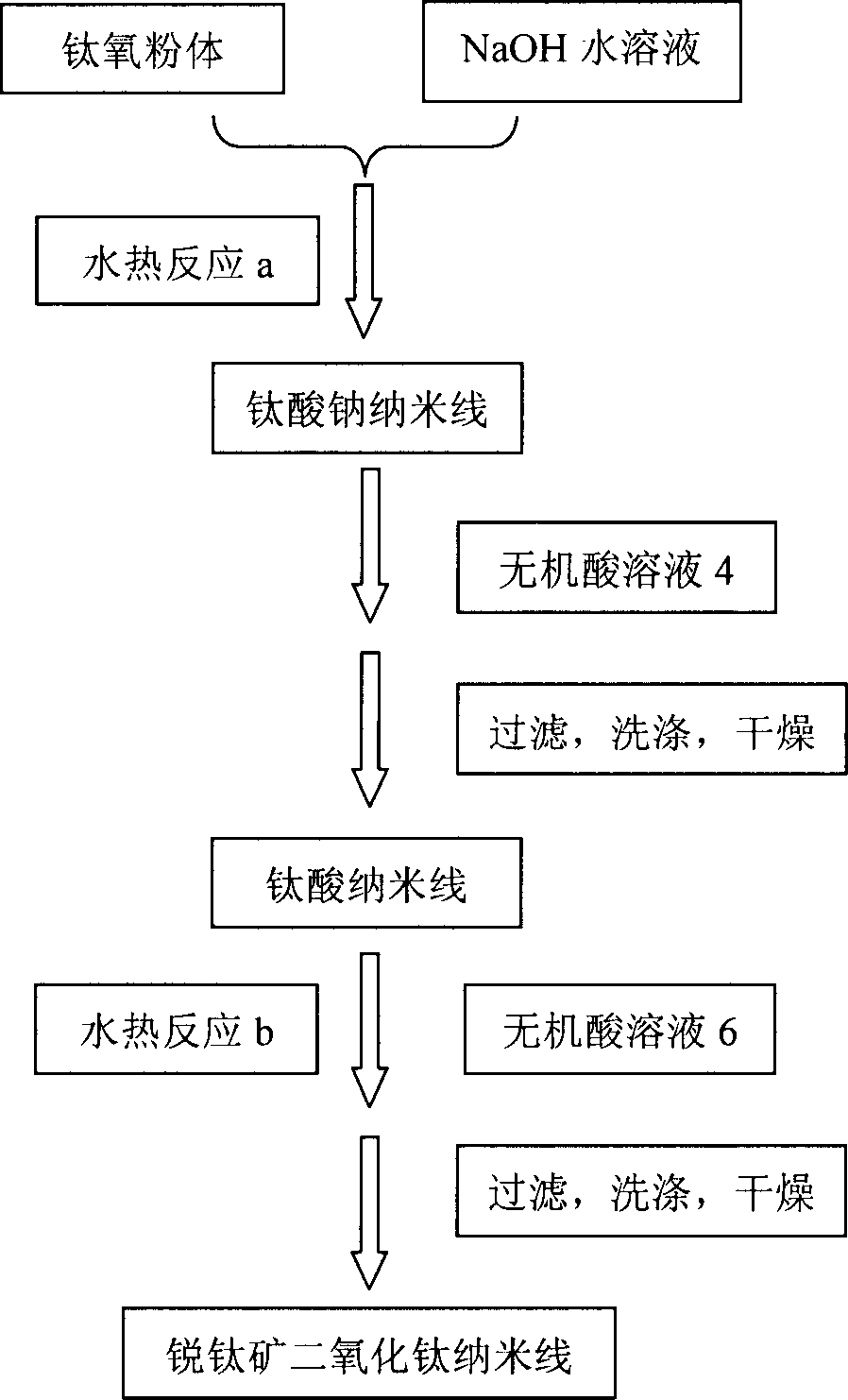

Method used

Image

Examples

Embodiment 1

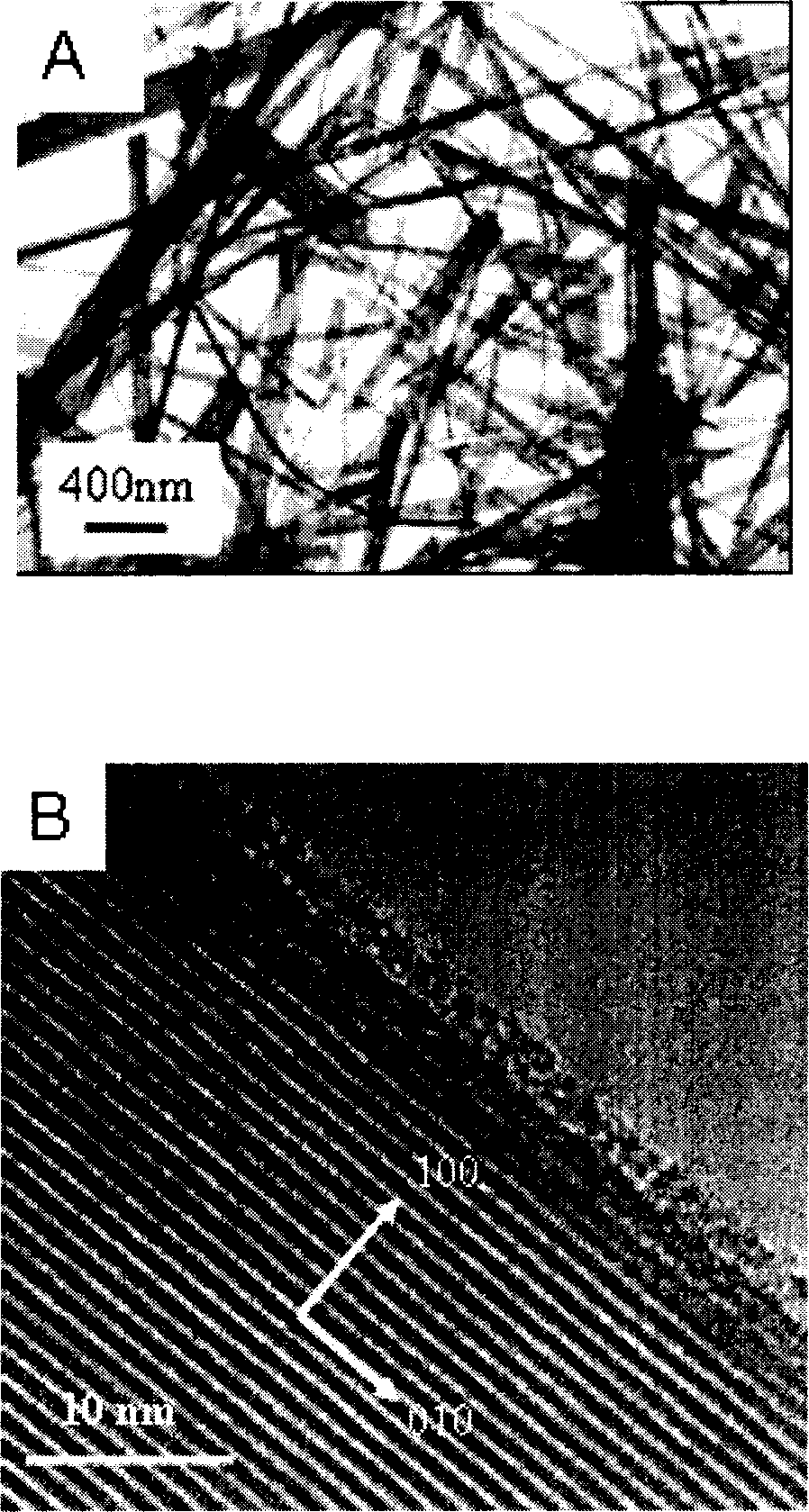

[0046] Disperse 1g of titanium oxide (Deguass P25) in 40mL of 5M sodium hydroxide solution, transfer the solution to a hydrothermal kettle, heat to 250°C, and keep the temperature constant for 48 hours. When the temperature of the reaction kettle drops to room temperature, take out the hydrothermal kettle , until the supernatant was dropped, the white solid at the bottom was transferred to a beaker, ultrasonically dispersed, washed with deionized water several times, and centrifuged until the pH of the washing liquid reached 9-11. Add 0.1M nitric acid solution until the solution becomes acidic, sonicate and let it stand for more than 6 hours, so that the H + The ions can convert the Na in the nanowire + The ions are fully exchanged out. Wash with deionized water several times, centrifuge until the pH of the washing solution is close to neutral, and dry at 80°C. Disperse 1-1.5g of titanic acid nanowires into 80mL of the above nitric acid solution with pH=7, transfer the solut...

Embodiment 2

[0048] Disperse 2g of metatitanic acid in 80mL of 10M sodium hydroxide solution, transfer the solution to a hydrothermal kettle, heat to 180°C, and keep the temperature constant for 10 hours. The supernatant and the white solid at the bottom were transferred to a beaker, ultrasonically dispersed, washed with deionized water several times, and centrifuged until the pH of the washing liquid reached 9-11. Add 0.1M hydrochloric acid solution until the solution becomes acidic, sonicate and let it stand for more than 6 hours, so that the H + The ions can convert the Na in the nanowire + The ions are fully exchanged out. Wash with deionized water several times, centrifuge until the pH of the washing solution is close to neutral, and dry under vacuum at 60°C. Disperse 1-1.5g of titanic acid nanowires into 80mL of the above nitric acid solution with pH=2, transfer the solution to a hydrothermal kettle, raise the temperature to 250°C, and keep the temperature constant for 1 hour. was...

Embodiment 3

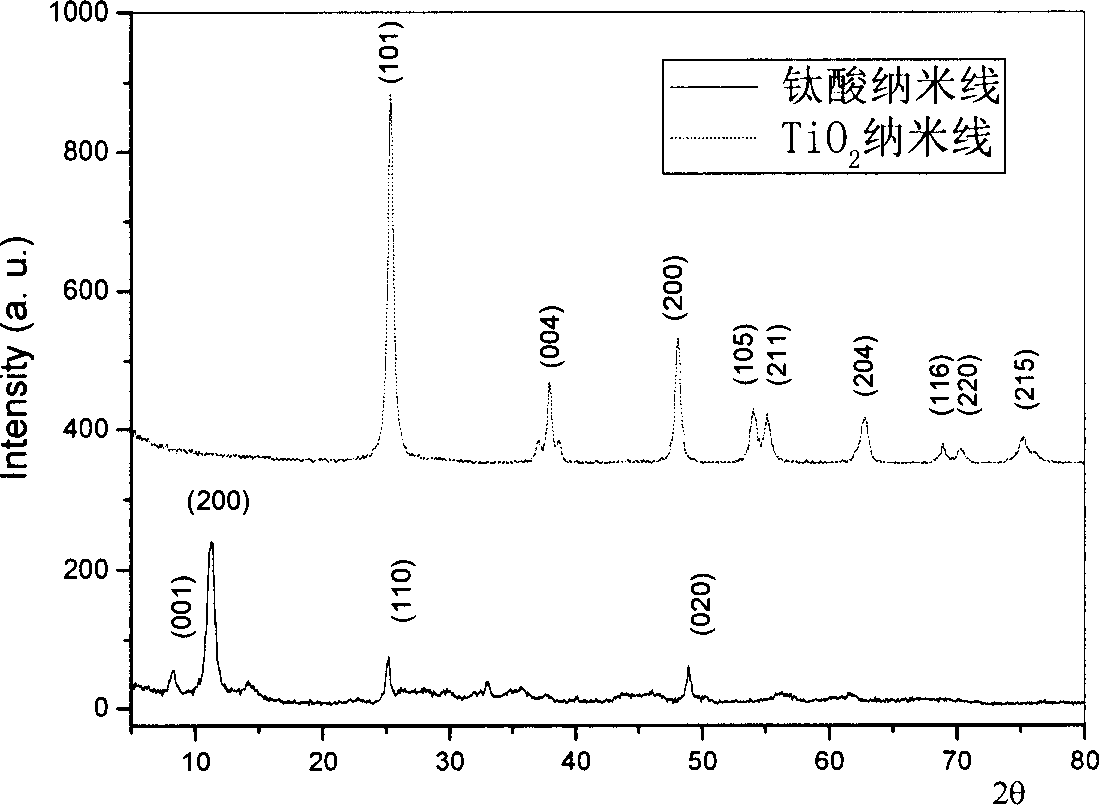

[0050] Comparative experiment: repeat the embodiment 2 of CN 1613585A

[0051] Put 25kg of metatitanic acid powder into the reaction kettle, add 10M NaOH aqueous solution, mix and stir evenly, heat to 160°C and keep at this temperature for 24h; when the reaction kettle is lowered to room temperature, open the reaction kettle to take out the product, and carry out Filter and wash with 0.1M dilute nitric acid, wash in water, and dry. Obtain the x-ray diffraction pattern (XRD) of product as Figure 6 As shown, it can be directly drawn from the spectrum that the product of this example is titanic acid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com