Magneto-thermo wax-proofing apparatus for oil exploitation

A technology of anti-wax and magnetic heat, which is applied in the direction of isolation device, earth square drilling and mining, cleaning equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings.

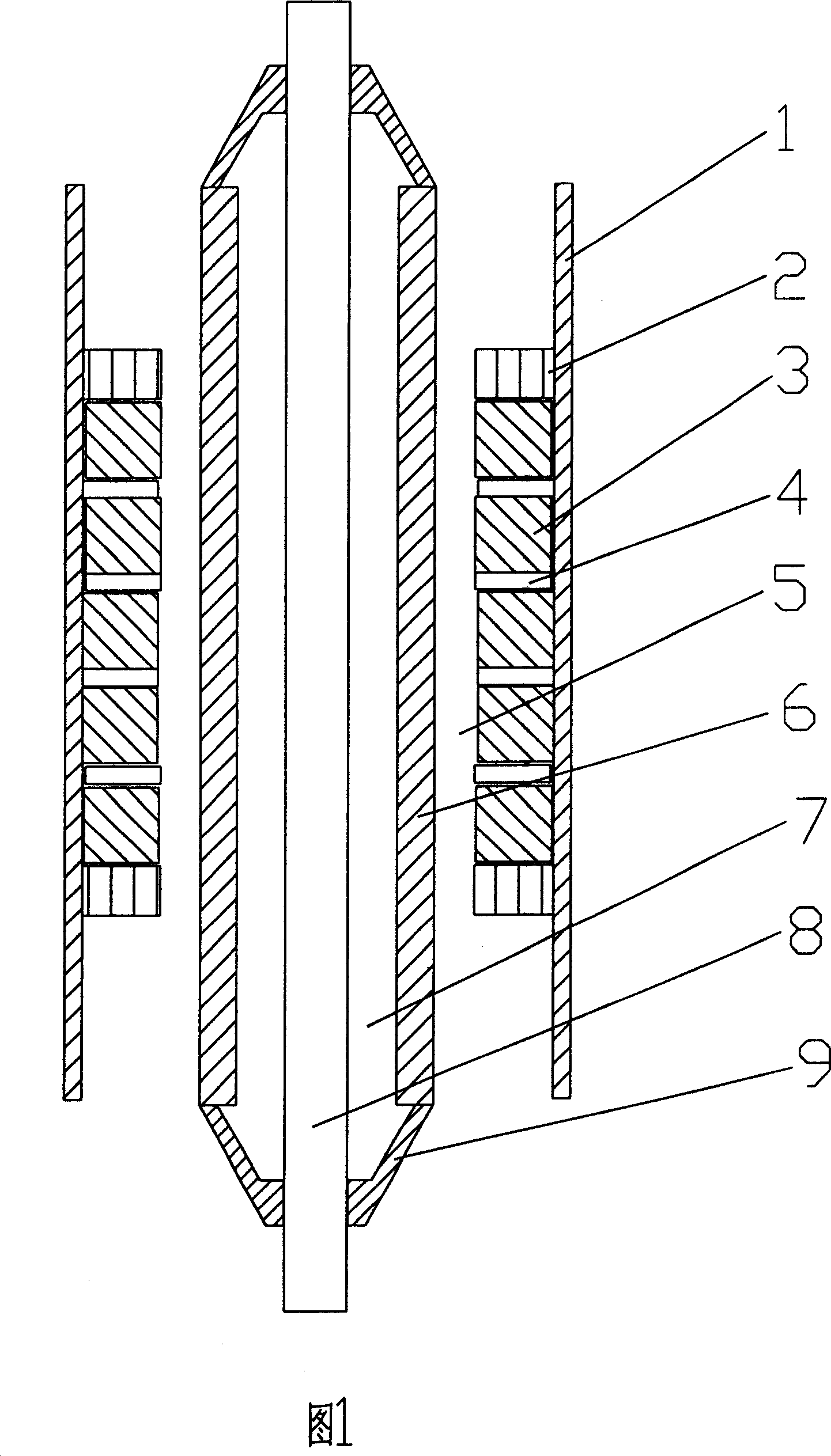

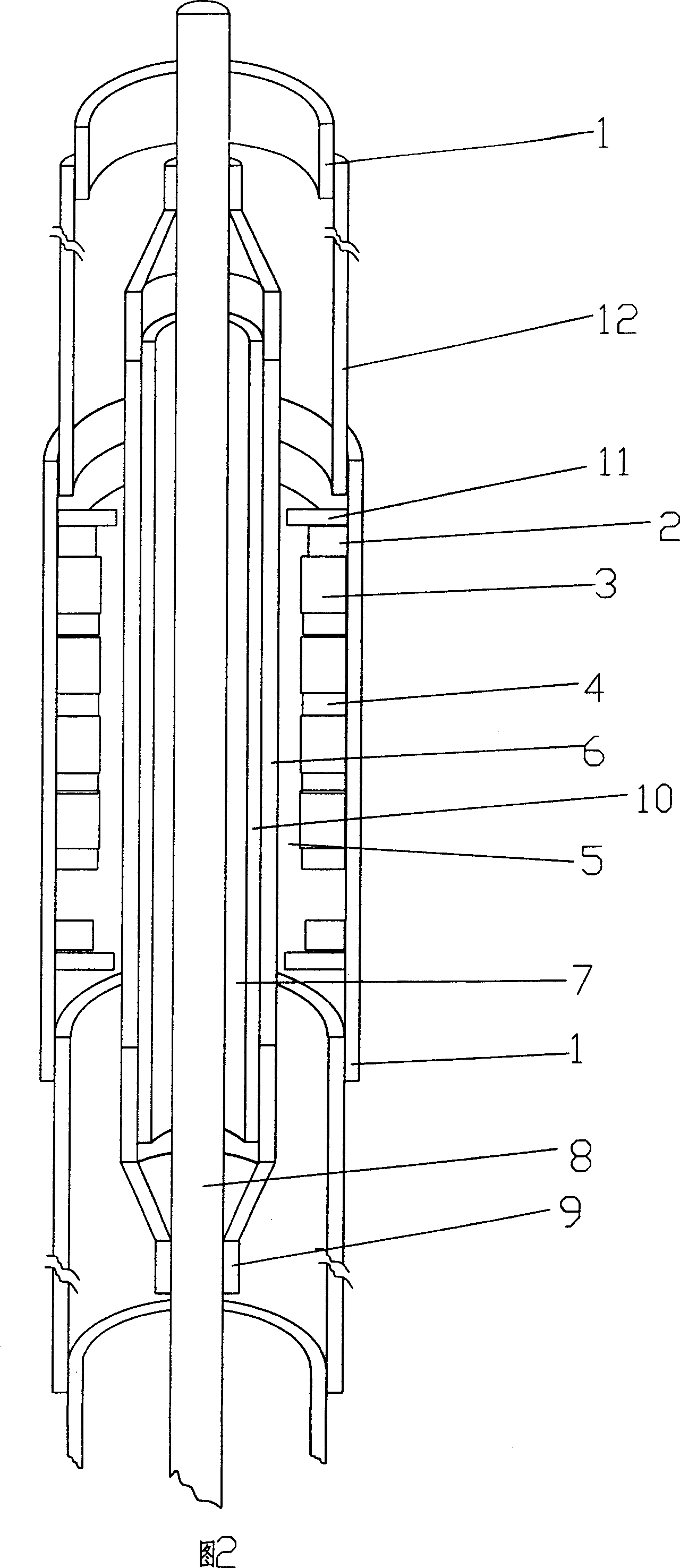

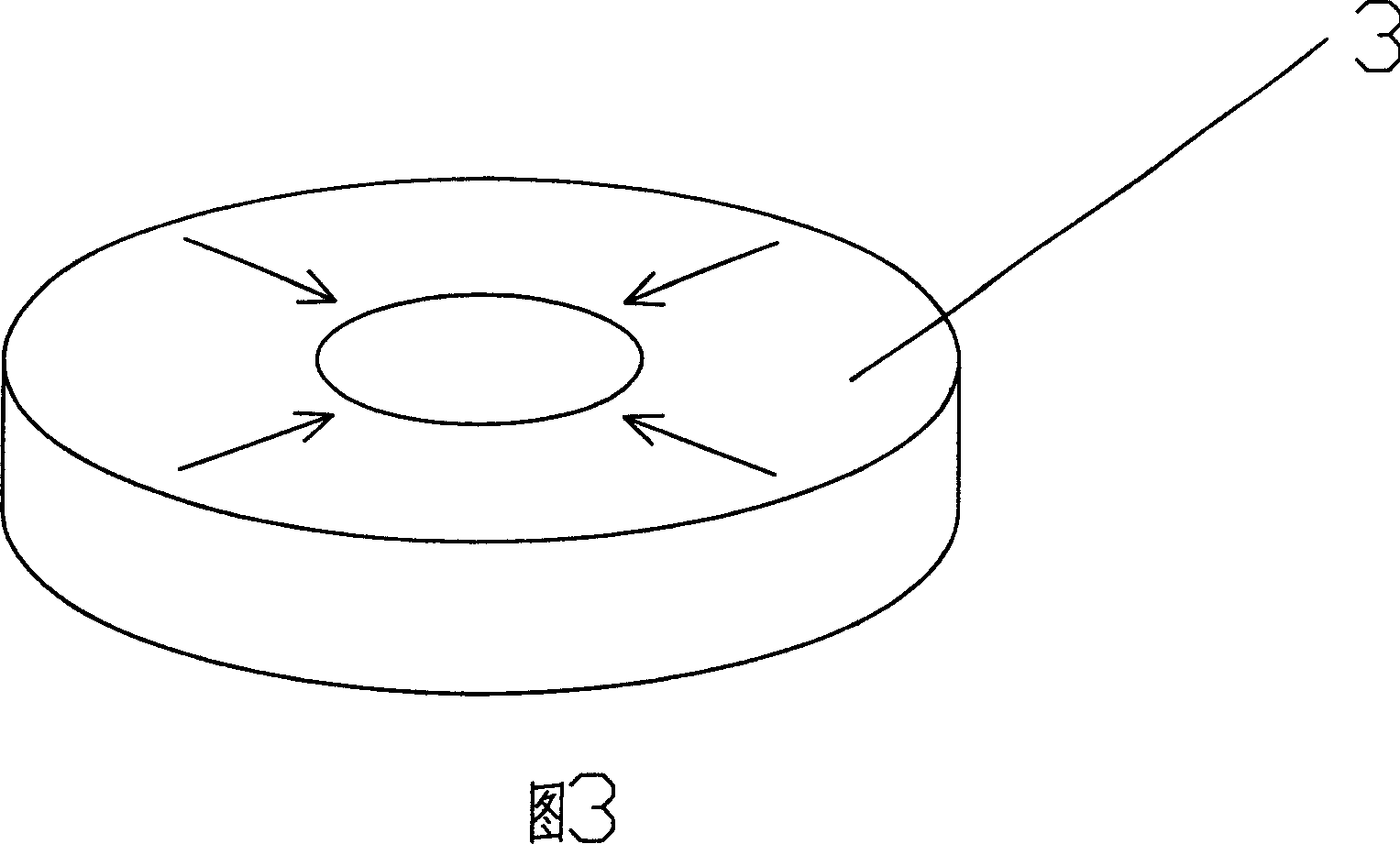

[0027] The invention is improved on the basis of the existing magnetic thermal wax-proof device. As shown in FIG. 2, the present invention includes a ring-shaped magnetic steel 3 fixed on the inner wall of the oil pipe 1 and a heating pipe 6 fixed on the sucker rod 8. Among them, the ring-shaped magnetic steel 3 is separated by a ring-shaped filler 4, and both ends of the ring-shaped magnetic steel 3 and the filler 4 arranged at intervals are fixed by a ring-shaped fixed block 2. The magnetic steel 3 is a neodymium iron boron magnetic steel, and the filler 4 is a non-magnetic non-metallic material. During the sucker rod 8 twitching process, the magnetic steel is protected to prevent it from breaking. The heating tube 6 is made of copper, copper alloy, aluminum, silver, etc. or other materials with high conductivity (relative conductivity greater than 60%, the higher the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com