TiN/AlON nano multilayer coating for cutting tool

A nano-multi-layer and cutting tool technology, which is applied in coatings, metal material coating processes, layered products, etc., can solve the problems that cannot meet the higher requirements of coating mechanical properties, low hardness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

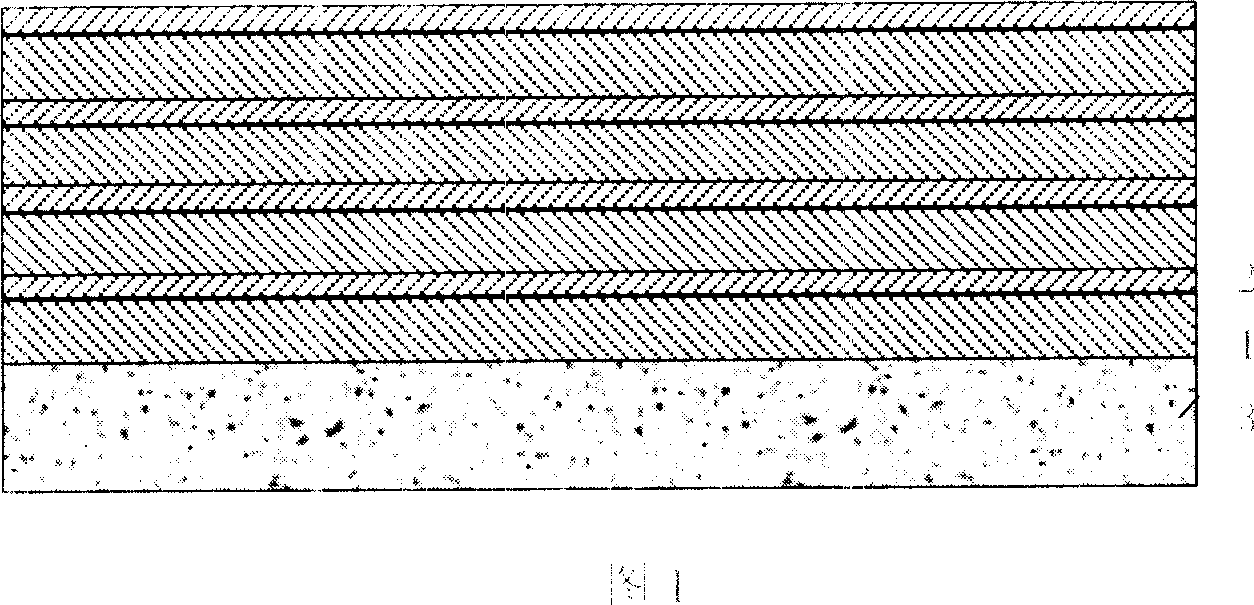

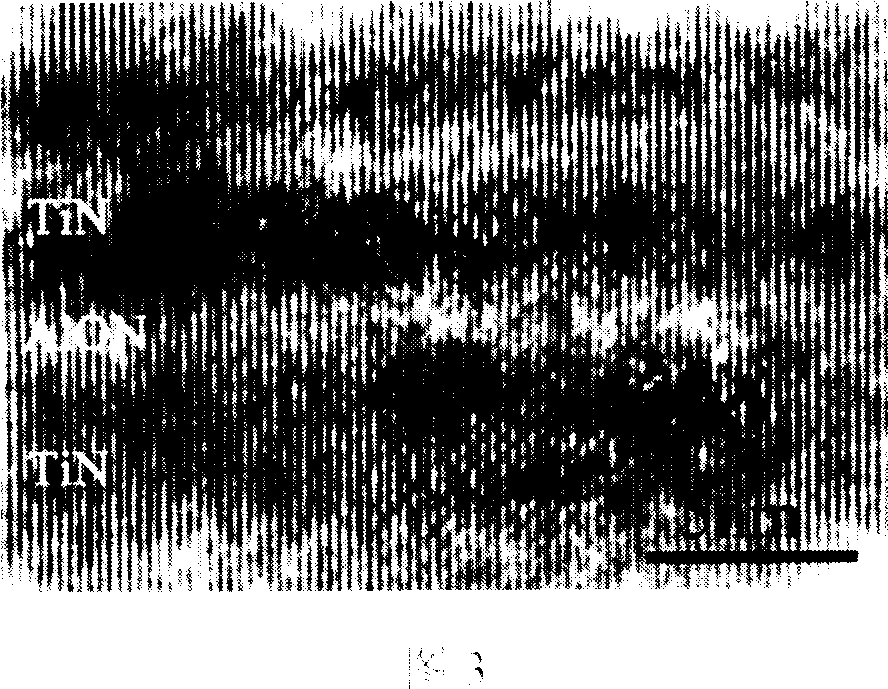

[0020] This embodiment consists of alternately depositing TiN layers 1 and AlON layers 2 on a metal or ceramic substrate 3 , the thickness of the TiN layer 1 is 3 nm, and the thickness of the AlON layer 2 is 0.3 nm. The total thickness of the thus obtained TiN / AlON multilayer coating is 2 μm, the ratio of N and O in the AlON layer is 0.3, and the hardness of the coating is 35 GPa.

example 2

[0022] This embodiment consists of alternately depositing TiN layers 1 and AlON layers 2 on a metal or ceramic substrate 3 . The total thickness of the TiN / AlON multilayer coating is 4 μm, the thickness of the TiN layer is 3 nm, and the thickness of the AlON layer is 0.5 nm. The ratio of N and O in the AlON layer is 0.3, and the hardness of the coating is 41 GPa.

example 3

[0024] This embodiment consists of alternately depositing TiN layers 1 and AlON layers 2 on a metal or ceramic substrate 3 . The total thickness of the TiN / AlON multilayer coating is 3 μm, the thickness of the TiN layer is 3 nm, and the thickness of the AlON layer is 0.8 nm. The ratio of N and O in the AlON layer is 0.3, and the hardness of the coating is 36 GPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com