Oxide based diluted magnetic semiconductor thin film with room temperature ferromagnetism and preparation method thereof

A room temperature ferromagnetic and dilute magnetic semiconductor technology, applied in the field of material science, can solve the problems of difficult regulation of ferromagnetism and low conductivity, and achieve the effects of stable product performance, high conductivity and strong repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

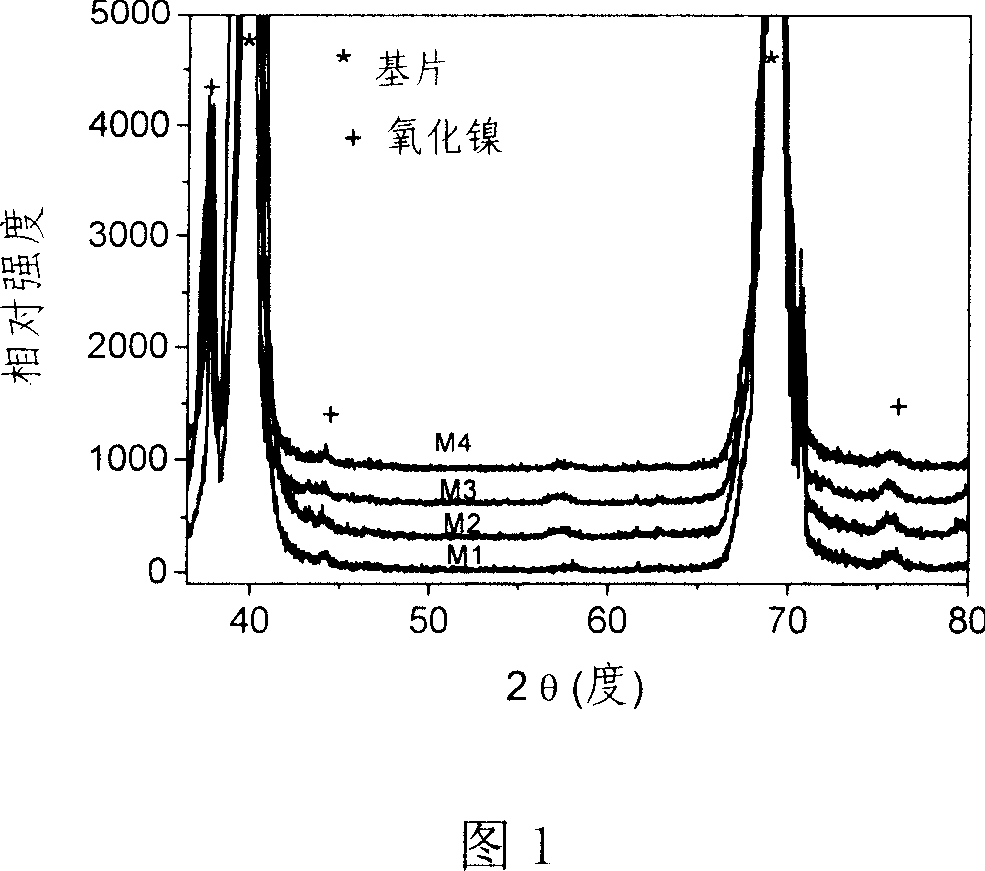

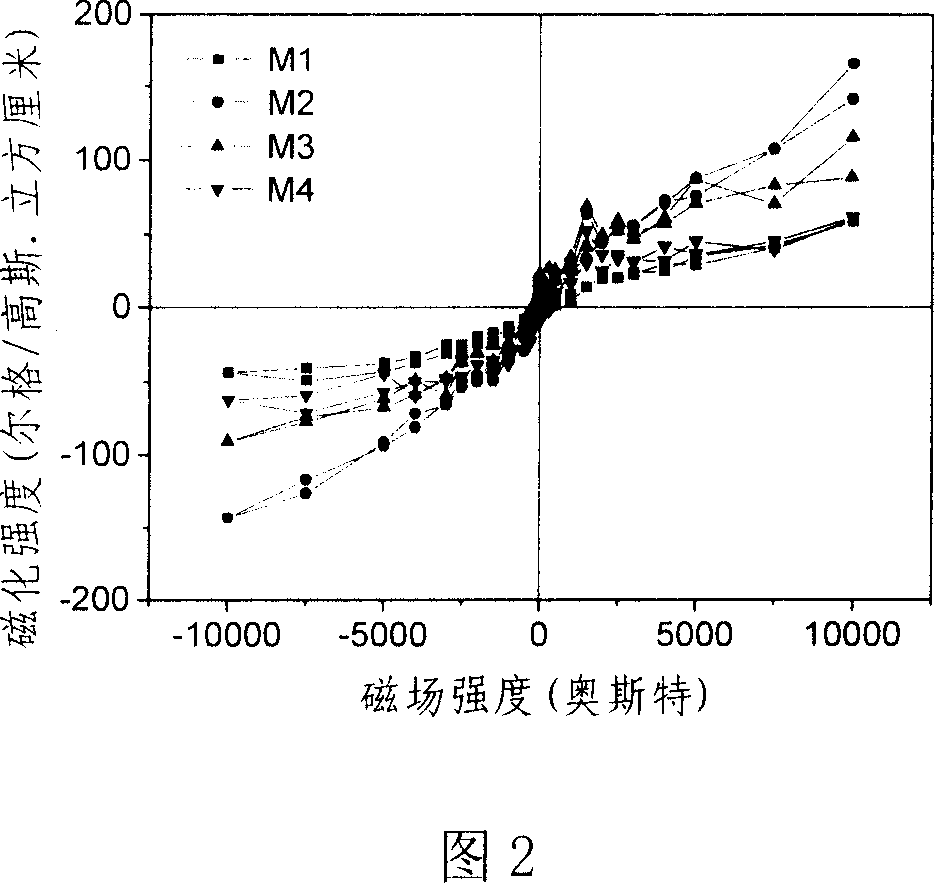

[0027]Embodiment 1: take by weighing appropriate amount of nickel nitrate, manganese nitrate, citric acid according to the formula in table 1, they are dissolved in ethylene glycol monomethyl ether together, add the concentration of 0.4mL after dissolving completely and be 0.1mol / L Lithium nitrate in ethylene glycol monomethyl ether solution, and finally sols of Li-Ni-Mn-O systems with different Mn contents were prepared. Use the above-mentioned sol, spin the film by spin coating, first dry the wet film, and then anneal in a rapid heat treatment furnace at 300 ° C, repeat this process until the required thickness, and finally anneal at 600 ° C, The desired film is obtained, and Fig. 1 shows the XRD curve of the film; Fig. 2 shows the M-H curve of the film.

[0028] Sample serial number

Embodiment 2

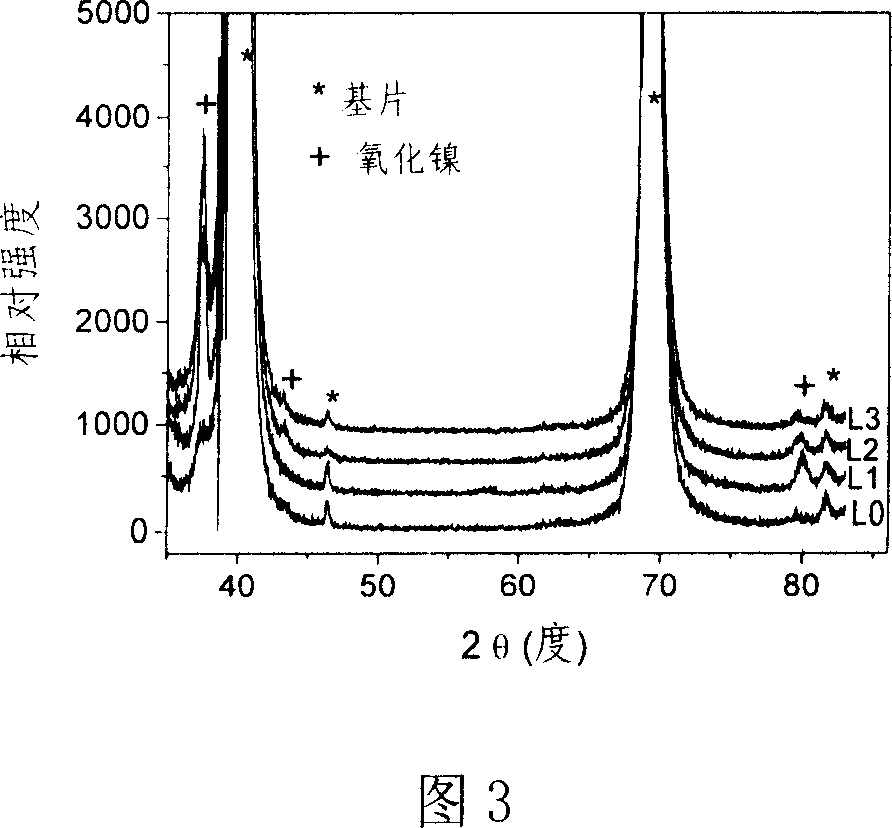

[0029] Embodiment 2: take by weighing an appropriate amount of nickel nitrate, manganese nitrate, citric acid according to the formula in table 2, they are dissolved in ethylene glycol monomethyl ether together, add the nitric acid that an amount of concentration is 0.1mol / L after dissolving completely Lithium ethylene glycol monomethyl ether solution, and finally the sols of Li-Ni-Mn-O systems with different Li contents were prepared. Use the above-mentioned sol, spin the film by spin coating, first dry the wet film, and then anneal in a rapid heat treatment furnace at 300 ° C, repeat this process until the required thickness, and finally anneal at 600 ° C, Get the desired film. Figure 3 shows the XRD curve of the film; Figure 4 shows the M-H curve of the film.

[0030] Sample serial number

Embodiment 3

[0031] Embodiment 3: take by weighing 0.564 gram of nickel nitrate, 0.016 gram of ferric nitrate, 0.546 gram of citric acid, they are dissolved in ethylene glycol monomethyl ether together, add 1ml concentration after dissolving completely and be the ethyl alcohol of the lithium nitrate of 0.1mol / L Glycol monomethyl ether solution, the final prepared proportioning is Li 0.01 Ni 0.97 Fe 0.02 Sol of O. Use the above-mentioned sol, spin the film by spin coating, first dry the wet film, and then anneal in a rapid heat treatment furnace at 300 ° C, repeat this process until the required thickness, and finally anneal at 600 ° C, Get the desired film. Figure 5 shows the XRD curve of the film; Figure 6 shows the M-H curve of the film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com