Miniature hot-air engine

A hot air engine and miniature technology, which is applied in the direction of hot air variable displacement engine devices, mechanical equipment, machines/engines, etc., and can solve problems such as inappropriateness, large size, and difficult implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

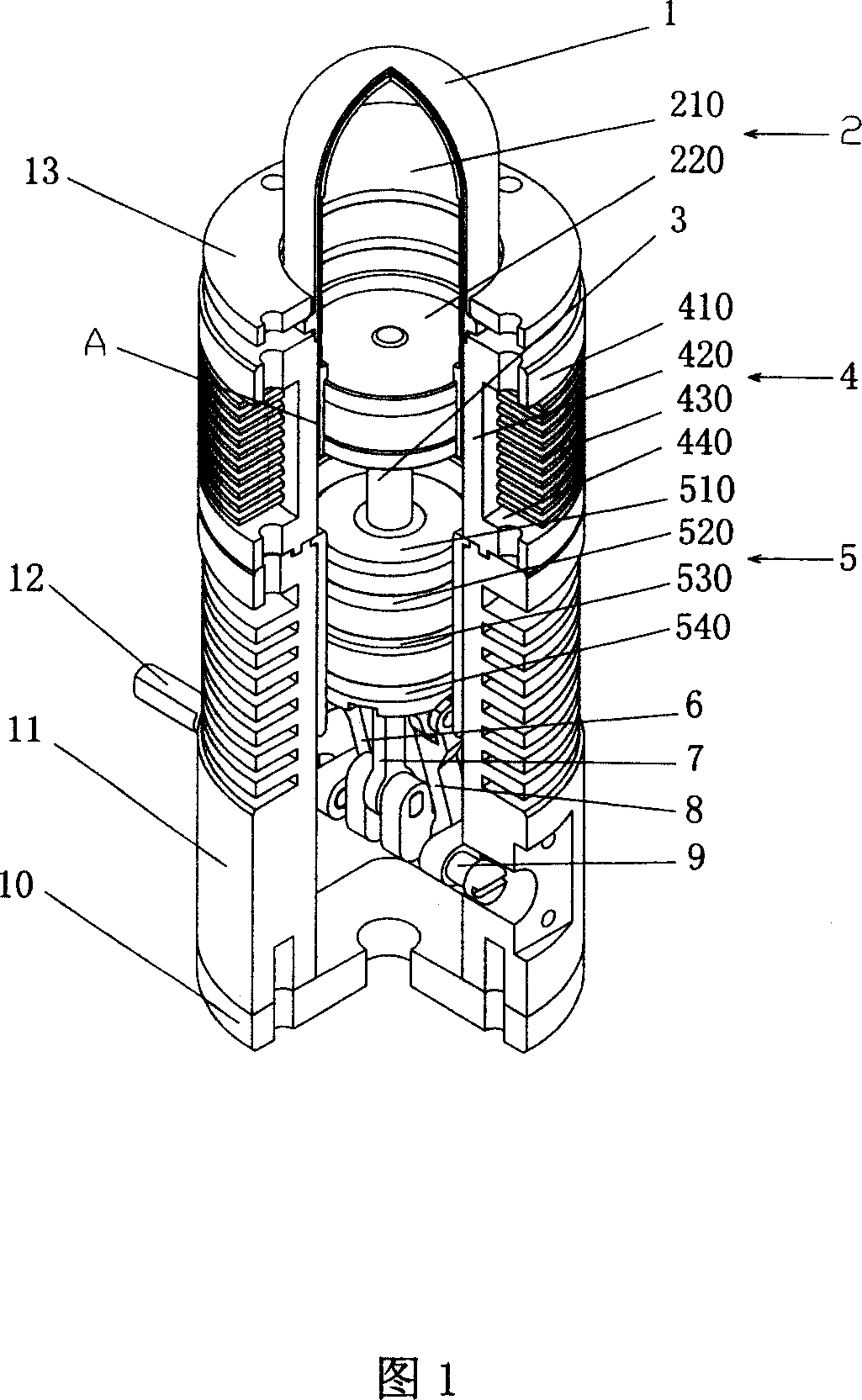

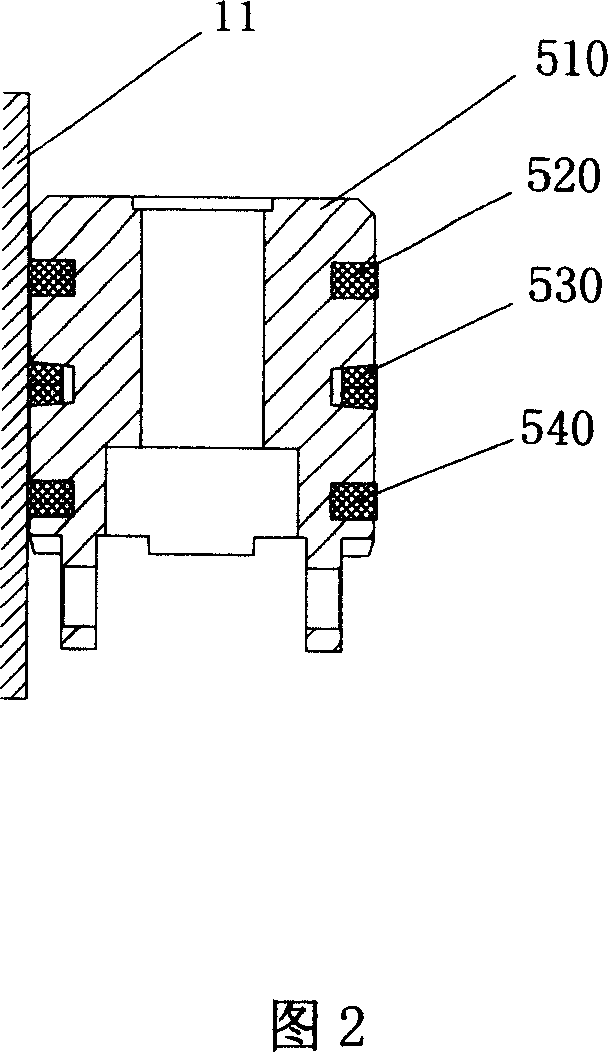

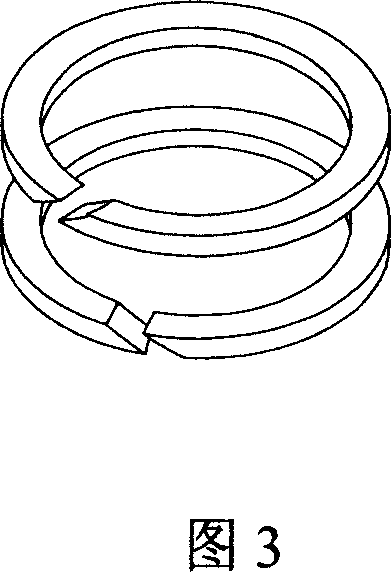

[0018] As shown in Figures 1, 2 and 3, it is an embodiment of the present invention. A cylindrical heater 1, a baffle plate 13, a cooler 4, a fuselage 11 and a bottom plate 10 are arranged on the outside in sequence from top to bottom, and a gas distribution piston is arranged in sequence from top to bottom inside the closed space formed by the above components. 2. Piston rod 3, power piston 5, connecting rods 6, 7, 8 and crankshaft 9 and other components. The heater 1 is a thin-walled cylindrical structure with a closed top, which is processed by heat-resistant metal, and is used to transfer the heat generated by the heating device of the heater to the working medium in the inner cavity, and push the piston to do work. The inner cavity of the heater 1 is adapted to the structure of the piston top 210 of the gas distributing piston 2 of the heater, and forms the gas distribution cylinder of the heater together with the cooler 4 inner cavity at the lower end. The heater 1 is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com