Instrument for measuring humidity ratio of treatment media and measuring method using same

A measurement method and technology of moisture content, applied in the field of tobacco industry, can solve problems such as difficulty in meeting high temperature measurement, inconvenient system adjustment in time, and environmental temperature requirements, etc., and achieve the effect of simple structure, small error and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

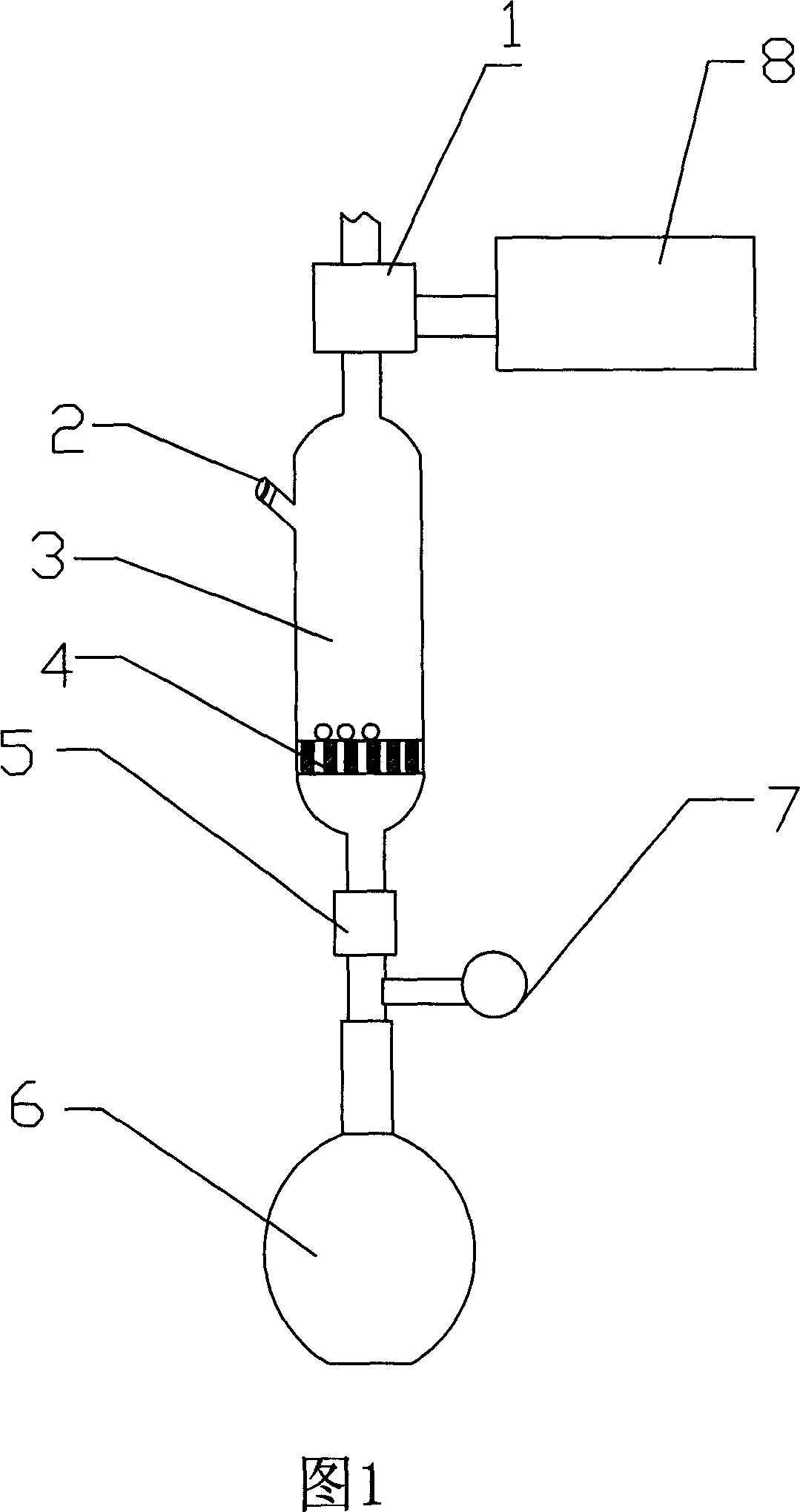

[0021] As shown in Figure 1, the measuring instrument for measuring the moisture content of the processing medium in the tobacco processing process; three-way valve 1, vacuum generator 8, flask 6, one-way valve 5, drier 3 and vacuum gauge 7, and drier 3 is provided with There is a distribution plate 4 with through holes, the distribution plate 4 is set in the lower part of the dryer 3, the desiccant is placed on the distribution plate 4, and the inlet for placing the desiccant is opened on the dryer 3, and the inlet is sealed by a sealing plug 2 . One end of the three-way valve 1 is connected to the drier 3, the other end is connected to the vacuum generator 8, the third end is the inlet of the test medium, the other end of the drier 3 is connected to the flask 6 through the one-way valve 5, and the side pipe of the flask 6 Connect with vacuum gauge 7.

[0022] Test object:

[0023] The moisture content of the process gas during the drying process of the shredded tobacco is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com