Fluorescent powder material, preparation method thereof and white light LED electric light source

A technology of phosphors and powders, applied in the directions of luminescent materials, chemical instruments and methods, circuits, etc., can solve the problems of low luminous intensity of fluorescent powders and inability to produce high-brightness white LEDs, etc., to improve luminous efficiency and improve mobile luminescence Wavelengths, effects of improving and shifting emission wavelengths

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Example 1: Phosphor (Tb 1.9 Y 0.5 Gd 0.5 Ce 0.1 )Al 5 O 12 Example of preparation

[0043] Select the raw materials according to the chemical structure formula of the above phosphors, the raw materials are selected from Tb 4 O 7 , Y(NO 3 ) 3 ·6H 2 O, Gd 2 O 3 , Ce(NO 3 ) 3 ·6H 2 O, Al(NO 3 ) 3 ·9H 2 O. Tb 4 O 7 , Gd 2 O 3 Dissolve in nitric acid to make the corresponding nitrate, then dissolve all the nitrate in deionized water to form an aqueous solution, control the concentration of the reactant to 2mol / L, and the acidity pH to 4.5. Add urea to the above solution to adjust The pH of the aqueous solution is 10.5, the concentration of the precipitating agent is 1mol / L, and it is stirred at 90°C to form a white jelly. The white jelly is calcined in the air at 900°C for 30 minutes to obtain the precursor. 50nm. Add flux HBO to the precursor 3 , The flux content is 5% of the total precursor. After mixing uniformly, place the mixture in the crucible, 2 -H 2 The calcination is...

Embodiment 2-11

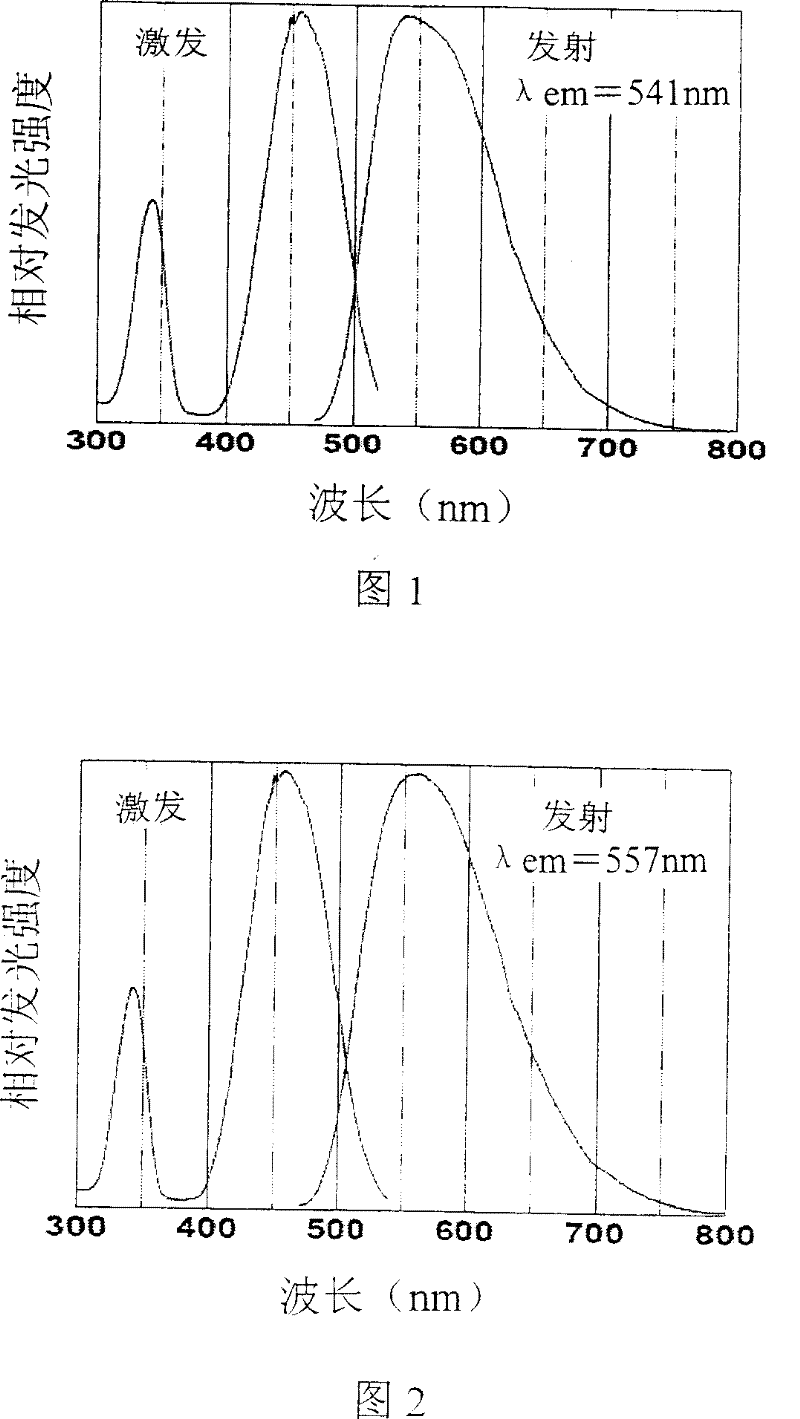

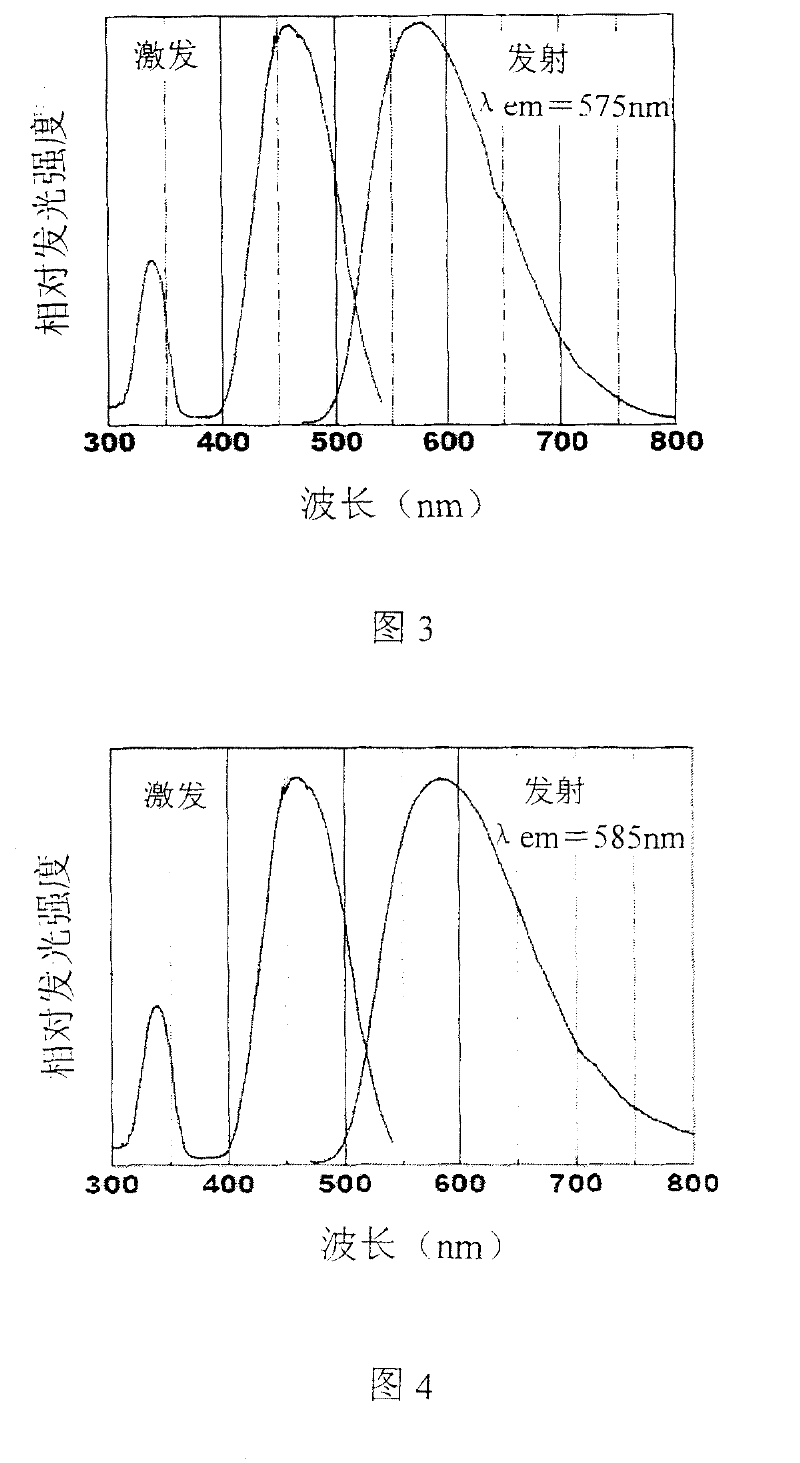

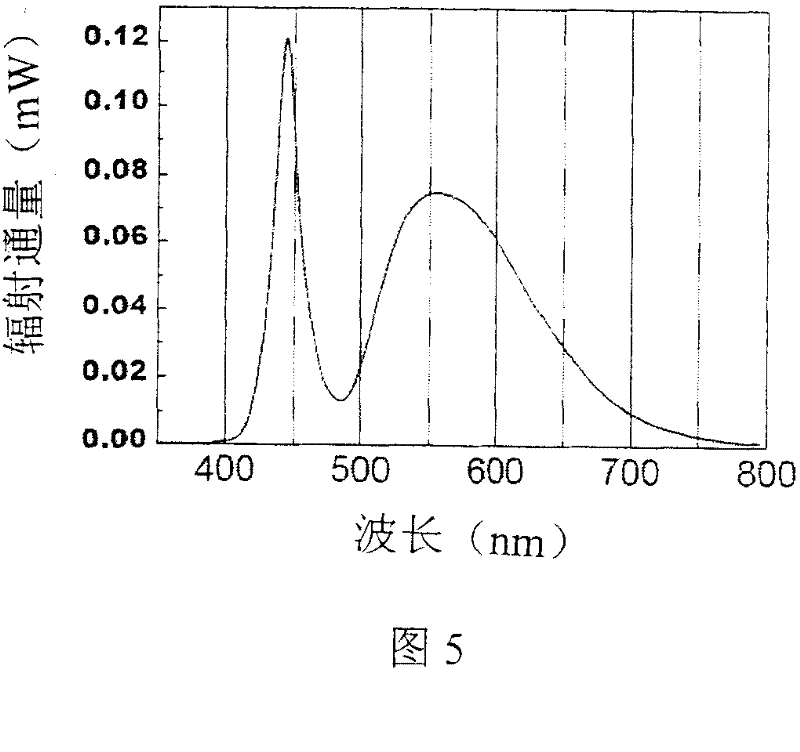

[0044] Example 2-11: Weigh the corresponding raw materials according to the chemical formula composition and stoichiometry of each example in Table 1. The preparation process is the same as that of Example 1. The emission peak and luminous intensity obtained under the excitation of 460nm wavelength light are shown in the table 1.

[0045] Table 1 Chemical formulas and luminescence characteristics of Examples 1-11

[0046] Example Chemical formula Emission peak light intensity 1(Tb 1.9 Y 0.5 Gd 0.5 Ce 0.1 )Al 5 O 12 541 1.6 2(Tb 2.9 Ce 0.1 )Al 5 O 12 562 1.5 3(Tb 2.4 Gd 0.5 Ce 0.1 )Al 5 O 12 551 1.4 4(Tb 2.4 Y 0.5 Ce 0.1 )Al 5 O 12 538 1.5 5(Tb 1.9 Y 0.5 Nd 0.5 Ce 0.1 )Al 5 O 12 539 0.8 6(Tb 1.9 Y 0.5 Lu 0.5 Ce 0.1 )Al 5 O 12 542 1.1 7(Tb 1.9 Y 0.5 La 0.5 Ce 0.1 )Al 5 O 12 543 0.9 8(Tb 1.9 Y 0.5 Sm 0.5 Ce 0.1 )Al 5 O 12 547 1.0 9(Tb 1.9 Y 0.5 Dy 0.5 Ce 0.1 )Al 5 O 12 542 0.7 10...

Embodiment 14

[0047] Example 14: Phosphor (Tb 1.7 Y 0.5 Gd 0.5 Lu 0.3 Ce 0.1 )(Al 3.5 Ga 1.0 In 0.5 )O 12 Example of preparation

[0048] Select the raw materials according to the chemical structure formula of the above phosphors, the raw materials are selected from Tb 4 O 7 , Y(NO 3 ) 3 ·6H 2 O, Gd 2 O 3 , Lu 2 O 3 , Ce(NO 3 ) 3 ·6H 2 O, Al(NO 3 ) 3 ·9H 2 O, In 2 O 3 , Ga 2 O 3 . Tb 4 O 7 , Lu 2 O 3 , Gd 2 O 3 , In 2 O 3 , Ga 2 O 3 Dissolve in nitric acid to make the corresponding nitrate, then dissolve all the nitrate in deionized water to form an aqueous solution, control the concentration of the reactant to 2mol / L, and the acidity pH to 4.5. Add ammonia water to the above solution to adjust the pH of the aqueous solution to 10.5 and the concentration of the precipitation agent to 2mol / L, and stir at 90°C to finally form a white gum. The white jelly was calcined in the air at 900℃ for 30min to obtain a precursor with a particle size of 50nm. Add flux HBO to the precursor 3 , The content of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com